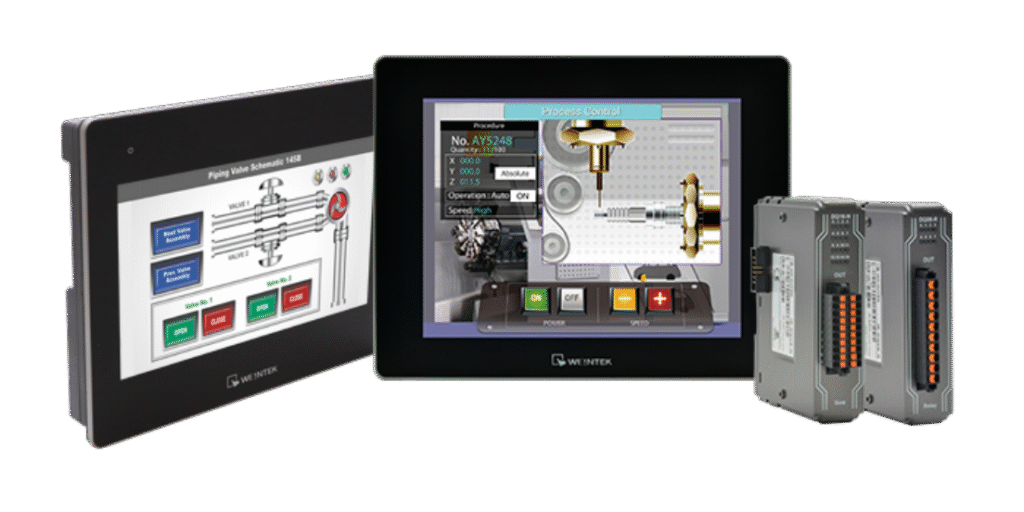

Communication Couplers & I/O Modules

After selecting your HMI, choose from a suite of easy to use powerful I/O modules to connect to your field equipment. We offer a complete set of I/O modules which can be combined with any of three communication couplers to create a remote I/O block.

Communication Couplers

I/O Modules

(up to 16 modules per Controller or Communication Coupler)

Documentation

Here’s the list of documents that support our Remote I/O products:

Need additional support? Contact us today.

User Friendly Configuration Software

Experience the freedom of configuring remote I/O without any cost.

Our free and user friendly configuration tool lets you easily design custom IO blocks by selecting digital and analog modules. With a straightforward interface, mapping them to your controller is seamless and stress-free. No hidden fees, no complicated steps—just simple setup to get your control systems up and running faster.

Industries Around the World

Improved traceability provides valuable data

Companies around the globe rely on Maple Systems products to help ensure uninterrupted production of critical resources. Whether you’re designing for a new application or updating an existing one, Maple Systems offers industrial automation and networking solutions that provide the connectivity, monitoring and control required to get the job done.

Read our Case Studies

See why our customers are so happy and continue to use our products year after year

Read Case Studies & Application Stories about how Maple Systems HMIs, OITs Industrial PCs, and HMI + PLCs are used in real-world applications. These case studies and success stories illustrate how our customers use our products to reduce costs while providing premium products and services.

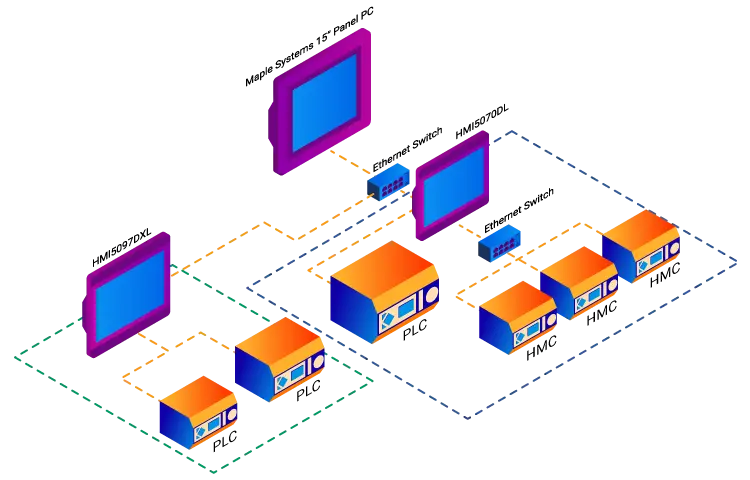

Supervisory Control and Data Acquisition (SCADA)

Early on, these types of systems were built using proprietary hardware and software, operating in isolation without connections to other networks. operators had to reside in a centralized control room or command center because human-machine interfaces (HMIs) did not support remote access. Any information provided to personnel other than operators was delivered via reports, which often had a significant time lag. Once devices were connected to much larger networks, they became more complex and gained broad capabilities.

To learn more about how our wifi products work together to create scalable SCADA solutions, visit our SCADA solutions page.