Class I, Division 2 HMIs

Maple Systems offers Class I, Div 2 certified HMIs designed to keep operators and their environment safe. Our CID2 HMIs are being used in a potentially dangerous environment or around flammable hazards everyday, and are designed to prevent dangerous explosions and ensure worker safety. These products are used in industries including oil and gas, mining, painting, chemical processing, pharmaceutical, food processing, and more.

HMI Accessories

$35.00

More Details$45.00

More Details

We offer custom communication cables to interface with over 300 protocols. Call us or see our Support Center for more details.

User Friendly HMI Configuration Software

Free, powerful HMI configuration software for our HMIs provides the flexibility to create and deploy custom control applications suited to your unique industrial process. With support for over 300 PLC & controller communication protocols, EBPro enables our HMIs to seamlessly integrate with your new or existing system.

Programmable Logic Controller (PLC) Connectivity

With over 300 PLC & Controller communication protocols, these HMIs will easily integrate with your preferred PLC brands, including:

Allen-Bradley

Siemens

Omron

Emerson

GE

Panasonic

Mitsubishi

...and many

more

Compatible PLCs

Select your preferred PLC brand from the list below for more information on how it can seamlessly integrate with Maple Systems HMIs.

Why Class 1 Division 2?

We offer many Class I, Div 2 certified solutions designed to keep operators and their environment safe. These products are used in industries including oil and gas, mining, painting, chemical processing, pharmaceutical, food processing, and more. C1D2 is an important factor to consider when looking for an HMI solution to use in hazardous industries.

A Class I, Division 2 location is:

- A location in which volatile flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are handled, processed, or used, but in which the liquids, vapors, or gases will normally be confined within closed containers or closed systems from which they can escape only in case of accidental rupture or breakdown of such containers or systems or in case of abnormal operation of equipment.*

- A location in which ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are normally prevented by positive mechanical ventilation, and which might become hazardous through failure or abnormal operation of the ventilating equipment.*

- A location that is adjacent to a Class I, Division 1 location, and to which ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors above their flash points might occasionally be communicated unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided.*

*www.termwiki.com

Industries Around the World

Improved traceability provides valuable data.

Companies around the globe rely on Maple Systems products to help ensure uninterrupted production of critical resources. Whether you’re designing for a new application or updating an existing one, Maple Systems offers industrial automation and networking solutions that provide the connectivity, monitoring and control required to get the job done.

Read our Case Studies

See why our customers are so happy and continue to use our products year after year

Read Case Studies & Application Stories about how Maple Systems HMIs, OITs, PLCs, Industrial PCs, and HMI + PLCs are used in real-world applications. These case studies and success stories illustrate how our customers use our products to reduce costs and excel in building projects with Class I, Division 2 applicaitons.

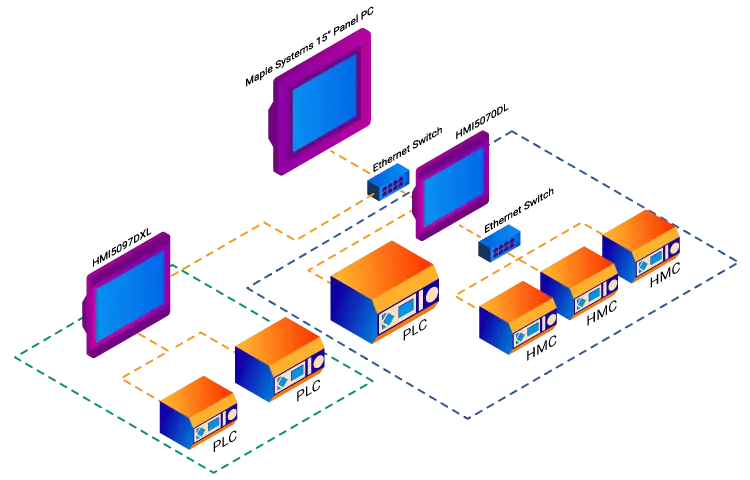

Supervisory Control and Data Acquisition (SCADA)

Early on, these types of systems were built using proprietary hardware and software, operating in isolation without connections to other networks. Operators had to reside in a centralized control room or command center because human-machine interfaces. (HMIs) did not support remote access. Any information provided to personnel other than operators was delivered via reports, which often had a significant time lag. Once devices were connected to much larger networks, they became more complex and gained broad capabilities

To learn more about how our Class I, Division 2 products work together to create scalable SCADA solutions, visit our SCADA solutions page.

Customize your HMI, HMI+PLC, or PC

Highlight your brand and differentiate your machine with a custom label

Company branding is a significant aspect of business marketing. By using custom labels on your products, you can create an identity to gain recognition from customers and potential buyers. It helps consumers recognize that the product was made by your company. Having this type of brand recognition can help your business stand out from competitors.

Our Custom Labels:- Fit Your Product Perfectly

- Offer Professional-Looking Packaging

- Strengthens Your Marketing Efforts

- Provides an Identity to Your Business

In this exclusive Design Guide, we review the types of HMIs — as well as their basic functions and new and emerging HMI functions and connectivity options. The role of HMIs in IIoT operations and the trend towards standardization (for both open source and proprietary setups) is also covered.