Wi-Fi Enabled

Our industrial Wi-Fi-enabled devices, having few installation and wiring restrictions, are ideal for mobile application, remote monitoring, and device maintenance. The HMI Wi-Fi access point allows smartphones or laptops to wirelessly connect to HMI allowing monitoring and maintenance of the HMI through your connected device. The Wi-Fi access feature can be easily enabled from a browser or on the HMI.

Results

-

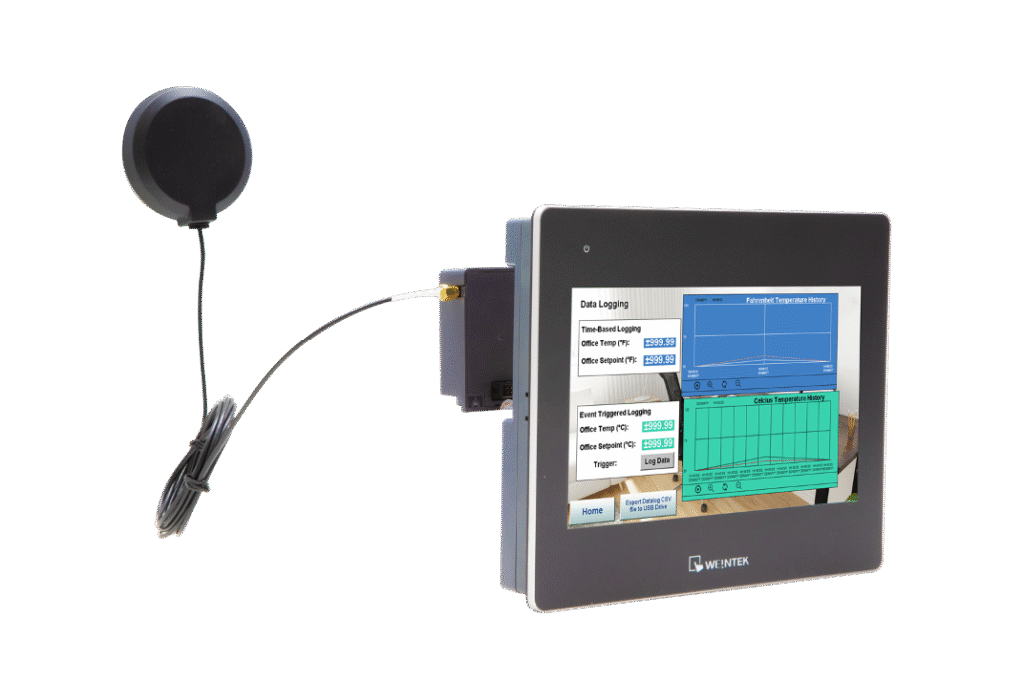

10.1″ cMT2108Xv2 and M02 Wi-Fi Enabling Package

- 10.1″ cMT2108X2V2 Advanced HMI

- UNBRANDED – With a sleek blank overlay, integrating this HMI into your machine is easy

- 2 Ethernet, 1 USB, 2 Serial Ports

- PDF Reader, Web Streaming, WebView, IP Camera, & CODESYS

- cMT2108X2V2 Data Sheet

- 6′ Magnetic Mounted Antenna

- Adds Wireless Network Connectivity

- Low-Profile, Simple Installation

- M02 Expansion Module Data Sheet

$988.00Quantity Discounts Available -

10.1″ cMT3102Xv2 and M02 Wi-Fi Enabling Package

- 10.1″ cMT3102Xv2 High Performance HMI

- 2 Ethernet, 1 USB, 2 Serial Ports

- PLC Web Browser, Barcode Scanner, IP Camera, Client & Server

- cMT3102Xv2Data Sheet

- 6′ Magnetic Mounted Antenna

- Adds Wireless Network Connectivity

- Low-Profile, Simple Installation

- M02 Expansion Module Data Sheet

$1,318.00Quantity Discounts Available -

10.1″ cMT3108XH and M02 Wi-Fi Enabling Package

- 10.1″ cMT3108XH High Performance, High Resolution HMI

- 2 Ethernet, 1 USB, 2 Serial Ports

- PLC Web Browser, Barcode Scanner, IP Camera, Client & Server

- cMT3108XH Data Sheet

- 6′ Magnetic Mounted Antenna

- Adds Wireless Network Connectivity

- Low-Profile, Simple Installation

- M02 Expansion Module Data Sheet

$1,438.00Quantity Discounts Available -

10.1″ cMT3108XP and M02 Wi-Fi Enabling Package

- 10.1″ cMT3108XP High Performance, High Resolution, Capacitive Touchscreen HMI

- 2 Ethernet, 1 USB, 2 Serial Ports

- PLC Web Browser, Barcode Scanner, IP Camera, Client & Server

- cMT3108XP Data Sheet

- 6′ Magnetic Mounted Antenna

- Adds Wireless Network Connectivity

- Low-Profile, Simple Installation

- M02 Expansion Module Data Sheet

$1,498.00Quantity Discounts Available -

10.1″ cMT3102Xv2R and M02 Wi-Fi Enabling Package

- 10.1″ cMT3102Xv2R High Performance HMI

- 2 Ethernet, 1 USB, 2 Serial Ports

- PLC Web Browser, RFID Scanner, IP Camera, Client & Server

- cMT3102Xv2R Data Sheet

- 6′ Magnetic Mounted Antenna

- Adds Wireless Network Connectivity

- Low-Profile, Simple Installation

- M02 Expansion Module Data Sheet

$1,318.00Quantity Discounts Available -

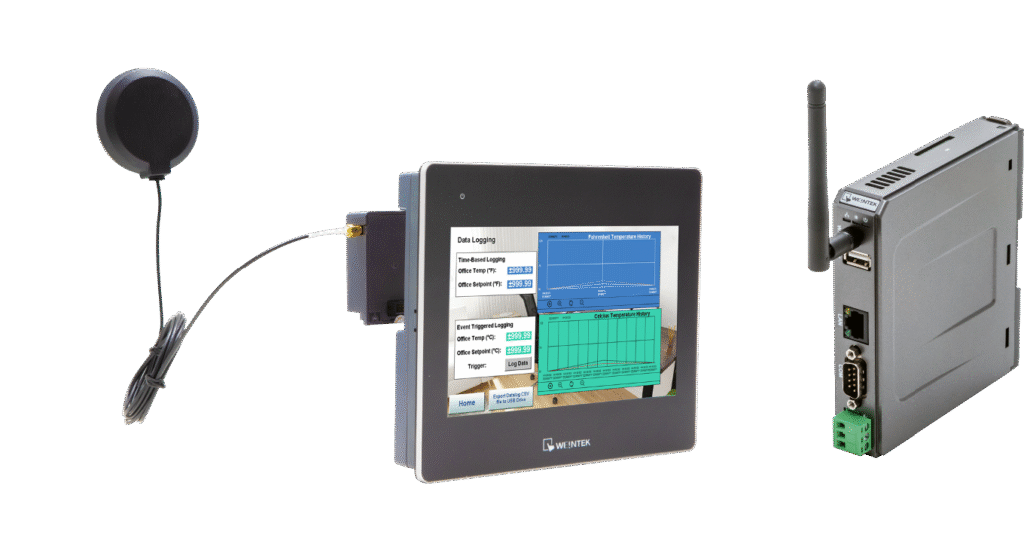

Headless HMI with Wi-Fi/EasyAccess License

cMT-SVR-202- Supports display on a tablet, laptop, smartphone, PC, or cMT iV Series

- Enhanced Security, Recipes, Data Logging, Barcode Scanner, Email, and more

- Remote Access, MQTT, OPCUA Client/Server, SQL Database, Wi-Fi Enabled, EasyAccess2.0 license included

- 1 Ethernet Port, 1 USB Port, 1 Serial Port, DIN-rail Mount, Micro SD Slot

- UL, CE, RoHS

$555.00Quantity Discounts Available -

Standard Headless HMI with Wi-Fi

cMT-SVR-200v2- Supports display on a tablet, laptop, smartphone, PC, or cMT iV Series

- Enhanced Security, Recipes, Data Logging, Barcode Scanner, Email, and more

- Remote Access, MQTT, OPCUA Client/Server, SQL Database, Wi-Fi Enabled

- 1 Ethernet Port, 1 USB Port, 1 Serial Port, DIN-rail Mount, Micro SD Slot

- UL, CE, RoHS

$450.00Quantity Discounts Available

User Friendly HMI Configuration Software

Free, powerful HMI configuration software for our HMIs provides the flexibility to create and deploy custom control applications suited to your unique industrial process. With support for over +400 PLC & controller communication protocols, EBPro enables our HMIs to seamlessly integrate with your new or existing system.

Programmable Logic Controller (PLC) Connectivity

With over +400 PLC & Controller communication protocols, these HMIs will easily integrate with your preferred PLC brands, including:

- Maple Systems

- Allen-Bradley

- Siemens

- Omron

- Emerson

- GE

- Panasonic

- Mitsubishi

- …and many more

Read more about connecting a Maple Systems PLC to one of our HMIs

Why a WiFi-Enabled HMI is the Right Choice

Adding a wifi-enabled HMI allows easily connect the display to the facility wireless network without running additional ethernet cable to the HMI

Whether you have a dedicated access point, such as a Wi-Fi Router or Cellular Modem, or whether you use Mobile Hotspots, you can connect to your Maple Systems Wi-Fi enabled HMI quickly and easily to receive the latest updates, make modifications to your application, or control your operations wirelessly. Read more information on the benefits of employing a Wi-Fi HMI.

Industries Around the World

Improved traceability provides valuable data

Companies around the globe rely on Maple Systems products to help ensure uninterrupted production of critical resources. Whether you’re designing for a new application or updating an existing one, Maple Systems offers industrial automation and networking solutions that provide the connectivity, monitoring and control required to get the job done.

Read our Case Studies

By adding Wi-Fi to their machine, OEM improved safety and productivity

Read about one of our OEM customers with large stainless steel rolling equipment who added an HMI with wifi for viewing alarm conditions and making adjustments to the parameters in the PLC and drives. In this application, the HMI was mounted at the end of the machine and connected securely to the plant Ethernet network. Adding the optional wifi module created an access point for the operator’s phone or tablet. This enabled operators to log in and remotely view the system right on their phone. They can adjust parameters, clear alarms, or diagnose issues on their phone as they walk around and observe operation of the machine. Read more about this application.

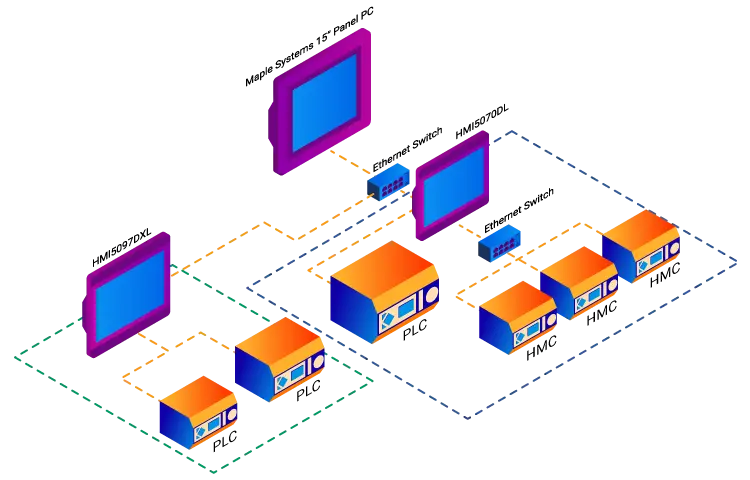

Supervisory Control and Data Acquisition (SCADA)

Adding a wifi-enabled HMI allows you to easily connect supported hardware to the facility wireless network

Early on, these types of systems were built using proprietary hardware and software, operating in isolation without connections to other networks. Operators had to reside in a centralized control room or command center because human-machine interfaces. (HMIs) did not support remote access. Any information provided to personnel other than operators was delivered via reports, which often had a significant time lag. Once devices were connected to much larger networks, they became more complex and gained broad capabilities.

To learn more about how our Class I, Division 2 products work together to create scalable SCADA solutions, visit our SCADA solutions page.

Customize Your HMI, HMI+PLC, or PC

Highlight your brand and differentiate your machine with a custom label

Company branding is a significant aspect of business marketing. By using custom labels on your products, you can create an identity to gain recognition from customers and potential buyers. It helps consumers recognize that the product was made by your company. Having this type of brand recognition can help your business stand out from competitors. Our Custom Labels:

- Fit Your Product Perfectly

- Offer Professional-Looking Packaging

- Strengthens Your Marketing Efforts

- Provides an Identity to Your Business