HMIs for Oil & Gas: Multi-Protocol Integration Without External Converters

Maple Systems HMIs are engineered for demanding Oil & Gas operations, delivering reliable performance in harsh environments and across complex multi-vendor networks. As an Oil and Gas HMI, instead of protocol converters, they feature built-in drivers, multiple communication interfaces, multi-session Ethernet support, and secure cloud connectivity. As a result, the HMI can connect directly to PLCs and field devices without additional gateway hardware – thereby simplifying integration, reducing project costs, and ensuring fast, real-time monitoring across pipelines, refineries, well pads, and offshore platforms.

Rugged Design for Harsh Environments

In the Oil & Gas industry, where operations are often spread across remote sites and harsh environments, reliable and efficient automation is critical. To meet these demands, Maple Systems HMIs provide a powerful solution by enabling easy integration with multiple PLCs and devices without the need for costly protocol converter hardware. Additionally with built-in drivers, multiple communication interfaces, and support for remote monitoring through cMT Viewer and IIoT cloud connectivity, these HMIs simplify complex networks while reducing installation costs and system complexity. As a result, from offshore platforms to refineries and pipeline networks, Maple HMIs offer a rugged, cost-effective, and future-ready solution for modern Oil & Gas automation challenges.

Built-In Protocol Integration

Maple Systems HMIs deliver true 2-for-1 value by combining a full-featured operator interface with powerful multi-protocol communication capabilities. Furthermore, using our free EBPro software, you can easily add drivers for widely used Oil & Gas PLCs such as ABB TotalFlow, Emerson ControlWave, ROC800, Rockwell, and FlowBoss 3000. As a result, the HMI can communicate directly with multiple devices – without needing a separate protocol converter or data gateway.

Moreover, because external protocol converters are often expensive, complex to configure, and another point of failure in the field, Maple HMIs help operators streamline installation and lower total system cost. In addition, in Oil & Gas environments where facilities frequently use equipment from multiple vendors, this “two devices in one” approach simplifies integration, reduces wiring and panel space, and accelerates deployment.

Ultimately, with Maple Systems HMIs, you get one device that does the job of two, making it easier and more cost-effective to build reliable, scalable automation systems.

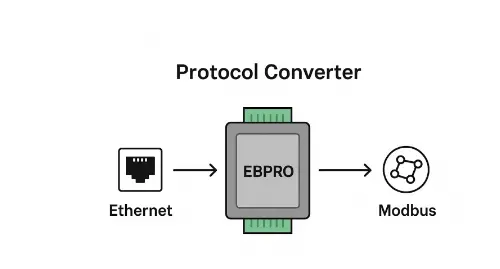

How EBPro Functions as a Built-In Protocol Converter

EBPro, the configuration software used with Maple Systems HMIs, enables the HMI to operate as a powerful protocol conversion gateway—a major advantage for Oil & Gas operations where equipment from different vendors must communicate reliably across long distances and harsh environments. In other words, instead of adding multiple external protocol converters, the HMI itself can translate between protocols, reducing hardware count and simplifying your field architecture.

How the Protocol Conversion Process Works in Oil & Gas Systems

- First, the HMI communicates with Device A using Protocol A

For instance, an upstream Oil & Gas site might use a PLC communicating over Modbus TCP or EtherNet/IP through the HMI’s Ethernet port. - Next, the HMI communicates with Device B using Protocol B

At the same time, the HMI can connect to field instruments – such as VFDs, flow computers, meters, or pressure transmitters – using Modbus RTU or another serial protocol. - Then, EBPro maps and transfers data between both protocols

You simply assign tags in EBPro that read from one driver and write to another. The HMI automatically handles the data exchange in the background, ensuring that mission-critical values move between devices without requiring additional gateways.

Why This Matters for Oil & Gas

Oil & Gas facilities often run a mix of PLCs, controllers, flow computers, and measurement equipment from multiple vendors. Because of this, EBPro’s protocol-mapping capabilities allow these devices to share information even if they use entirely different communication standards. Consequently, operators can:

- Reduce the number of protocol converters installed at the well pad or processing site

- Lower wiring and panel complexity

- Improve reliability by removing additional failure points

- Speed up deployment during commissioning or retrofit projects

Real-World Example

For example, consider a Modbus TCP PLC communicating through the HMI to a Modbus RTU VFD or flow computer.

In this scenario, the HMI reads a register from the Ethernet-based PLC, writes that data to a serial VFD or flow computer, collects the response, and delivers updated values back to the PLC. Once configured, the exchange runs continuously – ideal for pump control, flow measurement, or automated well management.

Connecting Maple Systems HMIs to PLCs Using Protocol Drivers

These steps provide a simplified overview of the setup process. For detailed instructions, advanced configuration options, and troubleshooting guides, here is a guide on our website.

Download and Install EBPro To begin, you must be registered and logged into the Maple Systems website to download EBPro. (Registration is free, and the software is free as well.)

Start your project

Next, launch EBPro, create a new project—or open an existing one—and select the HMI model you are using.

Configure the communication protocol

In the System Parameters dialog, navigate to the Device tab and click New Device/Server…. Choose the appropriate driver for your controller (e.g., Modbus TCP/IP, Siemens S7), then enter the required settings such as IP address, station number, or COM port.

Map registers or tags

With the device configured, assign HMI objects—such as lamps, numeric displays, and trend charts—to the controller’s register or tag addresses. In EBPro, simply select the device you created and enter the correct address for each object.

Download and test the project

Finally, upload the project from your PC to the HMI via Ethernet or USB. Then connect the HMI to the controller and verify communication by testing the mapped objects.

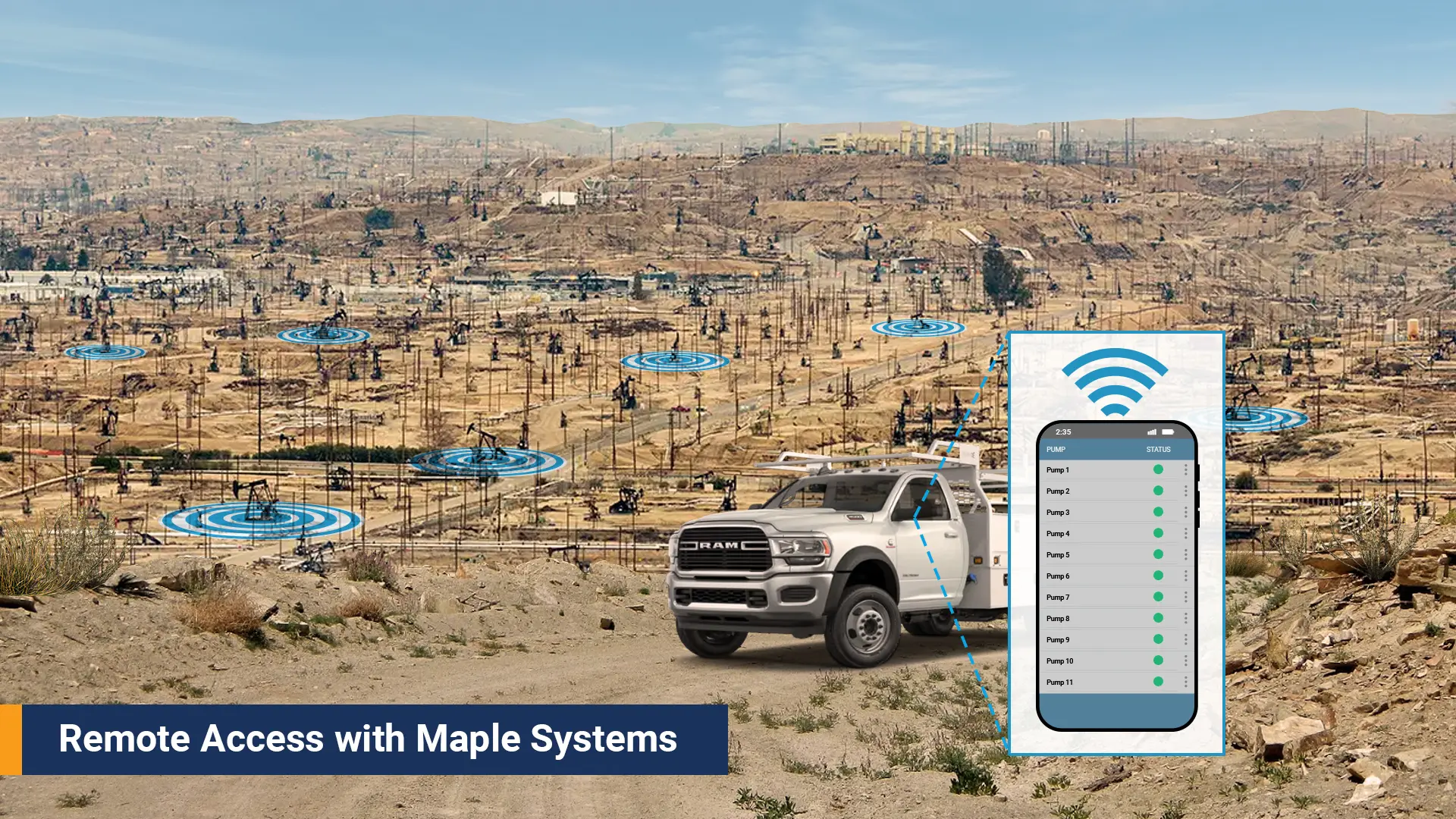

Multi-Session Ethernet Controller

Maple Systems cMT-series HMIs are built for environments where multiple people need access to the same system at the same time. With this in mind, the free cMT Viewer application allows up to 10 users to connect simultaneously to a single HMI over Ethernet or Wi-Fi. Whether on a PC, tablet, or phone, each user can view screens, acknowledge alarms, or adjust settings without interrupting anyone else’s session. Therefore, this capability is ideal for operations teams, maintenance crews, and remote engineers who all require real-time visibility into the process.

Additionally, because cMT Viewer runs the HMI project directly on the client device, the HMI doesn’t waste CPU resources rendering graphics for multiple remote users. Instead, it focuses on reading and writing data to the PLCs. Consequently, this architecture keeps performance fast and responsive even when several sessions are active, and it dramatically reduces network load compared to streaming full-screen video.

Furthermore, beyond supporting multiple users, a single cMT HMI can communicate with up to 64 connected PLCs or field devices within one project. This means you gain a centralized hub for systems that rely on mixed equipment—common in Oil & Gas and other industries where devices from many vendors must work together. As a result, you can pull data from dozens of controllers, unify it on one interface, and give your team shared access without adding extra gateways or servers.

Overall, the multi-session Ethernet capability gives you collaborative access for your team, high-performance HMI operation, and the ability to consolidate many controllers under one device – reducing hardware cost and simplifying your entire architecture.

Multiple Communication Interfaces

Maple Systems HMIs are built with a wide range of communication interfaces to support the diverse equipment found in upstream, midstream, and downstream Oil & Gas applications. In many cases, with onboard Ethernet, serial, and USB ports, these HMIs allow operators to connect PLCs, flow computers, meters, sensors, and SCADA networks without adding third-party gateways or expansion hardware. This versatility makes them an ideal choice for well pads, pump stations, compressor sites, and custody-transfer systems where reliability and compatibility are essential.

High-Speed Ethernet for Multi-Protocol Integration

Most Maple Systems HMIs include one or more RJ-45 Ethernet ports, giving you high-speed connectivity to PLCs, RTUs, and remote networks. Additionally, these Ethernet ports support popular Oil & Gas protocols such as Modbus TCP, EtherNet/IP, and MQTT, allowing you to pull data from flow computers, communicate with control systems, or send telemetry to cloud dashboards. Likewise, with EBPro’s multi-driver capability, a single HMI can communicate with dozens of devices at once and route data between them – significantly reducing the need for external protocol converters.

Serial Ports for Legacy and Field Instruments

Oil & Gas operations commonly rely on serial-based instruments such as VFDs, valve controllers, tank-level sensors, and pressure transmitters. To support this, Maple Systems HMIs include RS-232, RS-485, and RS-422 (2 or 4 wire) interfaces. As a result, these serial ports allow technicians to connect directly to field equipment using protocols like Modbus RTU without needing extra hardware. This is especially important for older wells and field assets that still operate on serial infrastructure but require modern visualization and data collection.

USB Ports for Data Logging and Service

Everyday Oil & Gas operations require reporting, manual data pulls, configuration backups, and firmware updates. To support these needs, Maple HMIs include both USB Host and USB Device ports for data logging to thumb drives, loading project files, exporting alarm histories, or performing routine maintenance. Moreover, for remote or unmanned sites, USB storage provides a simple and reliable way for technicians to plug in, extract data, and go—minimizing service time in hazardous or hard-to-reach locations.

C1D2 HMIs: Ready for Hazardous Locations

Maple Systems Class I, Division 2 (C1D2) HMIs feature the same communication flexibility as standard units, yet they are specifically engineered for hazardous locations where flammable gases may be present. To support diverse field requirements, these HMIs also provide multiple Ethernet ports, serial interfaces (RS-232/485), and USB connections, allowing them to integrate seamlessly with a wide range of Oil & Gas equipment—including PLCs, RTUs, flow computers, sensors, and VFDs.

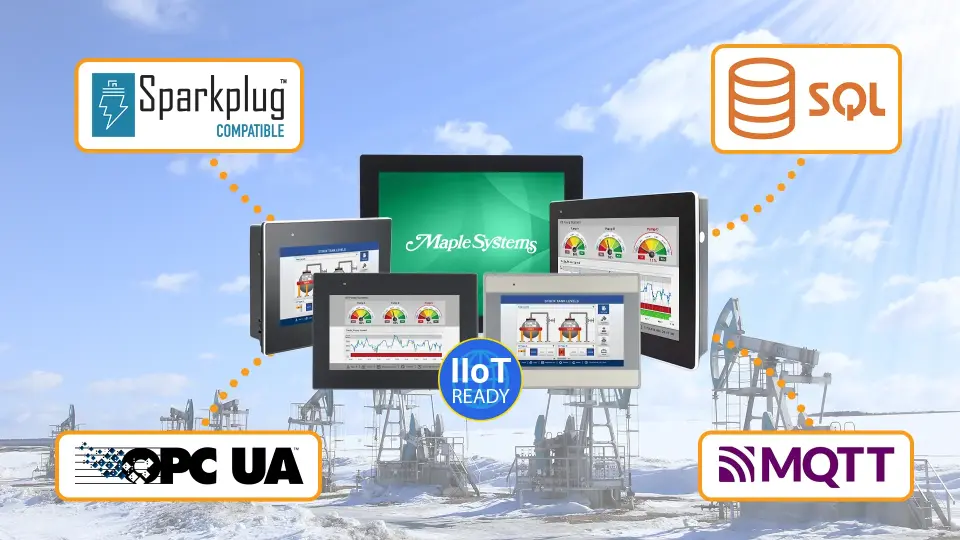

IIoT and Cloud Connectivity

Modern Oil & Gas operations rely on fast, secure access to real-time data – from production rates and tank levels to alarms, diagnostics, and remote control. To support these demands, Maple Systems HMIs are designed with built-in IIoT and cloud capabilities that make it easy to connect field devices to enterprise systems without adding extra hardware.

With this in mind, native support for MQTT, Sparkplug B, OPC UA, and SQL database integration allows Maple HMIs to function as powerful edge gateways – publishing process data to SCADA, historians, and cloud dashboards in a secure and efficient format. As a result, operators can remotely monitor assets, receive alerts, trend performance data, and troubleshoot issues from anywhere. This ultimately reduces the need for costly site visits and improves visibility across widely distributed assets such as well pads, tank batteries, and compressor stations.

Furthermore, Maple’s remote access tools – such as VNC, WebView, and the cMT Viewer – enable technicians and engineers to securely view and interact with the HMI in real time. This, in turn, empowers teams to identify problems sooner, optimize production, and make informed decisions without stepping foot on-site. By integrating IIoT features directly into the HMI, Maple Systems eliminates the need for separate gateways, protocol converters, or expensive cloud-ready PLCs, making it a cost-effective solution for digital transformation in Oil & Gas.

Maple Systems HMIs: Class I, Division 2 Certified

Maple Systems Class I, Division 2 (C1D2) HMIs HMIs are designed specifically for hazardous locations that require safe, rugged, and reliable operator interfaces. To ensure long-term durability, they feature aluminum enclosures, wide operating temperature ranges, and IP66/NEMA 4 protection to withstand harsh oil & gas, chemical, and industrial environments. Additionally, with support for dual Ethernet, serial ports, USB, and CANbus, they integrate easily into existing control systems. Furthermore, they include built-in drivers for major PLC brands (ABB TotalFlow, ControlWave, ROC800, Rockwell, FlowBoss 3000), as well as OPC UA, MQTT, and advanced functions like a PDF viewer, web browser, remote access, and IIoT connectivity. Certified for UL and C1D2, Maple’s HMIs deliver the durability and security needed for critical operations in hazardous areas.

Below are several examples of Maple Systems Class 1 Division 2 HMIs.

7″ High Brightness HMI

cMT3072XHTL

Class 1 Division 2 (C1D2) certified engineered for hazardous Oil & Gas environments.

Perfect for well pads, compressor stations, and tank battery control rooms.

Rugged aluminum enclosure with IP66 / NEMA 4 front-panel protection built to endure dust, spray, and harsh industrial conditions.

Ensures reliable performance in remote field locations.

Extended-temperature operation from -20 °C to 55 °C (-4 °F to 131 °F) Makes it suitable for the extreme climate conditions commonly found in Oil & Gas sites.

High-brightness 7″ display (1200 nits) with wide viewing angle optimized for outdoor and high-glare Oil & Gas environments.

As a result, operators can clearly read process data in direct sunlight or bright ambient light.

Compact 7″ form factor saves panel space while still providing clear, usable visualization for field operators.

In many cases, this makes it ideal for tight enclosures and retrofit projects in existing Oil & Gas panels.

Multiple I/O interfaces: (2) Ethernet ports and (2) serial ports (RS-232 / RS-485) flexible connectivity for legacy and modern control equipment.

Simplifies integration of RTUs, flow computers, PLCs, and SCADA networks on the same HMI.

Built-in IIoT & cloud support: MQTT, OPC UA, SQL database integration, and remote access capability ready for remote monitoring and analytics.

Accordingly, it enables connected Oil & Gas operations with real-time production data, alarms, and diagnostics accessible from anywhere.

10″ Wi-Fi Capable HMI

cMT3108XH

Class 1 Division 2 (C1D2) and ATEX Zone 2/22 certified – engineered for hazardous Oil & Gas environments.

Ideal for wellheads, compressor stations, tank batteries, and areas with flammable gases or vapors.

Rugged IP66 / NEMA 4 front panel – built for harsh outdoor and industrial field conditions.

Because of this, it withstands dust, water spray, vibration, and demanding Oil & Gas environments.

10.1″ high-resolution WVA touchscreen (1280×800) – clear visibility in bright sunlight and field applications.

Wide viewing angle improves operator usability in remote and outdoor Oil & Gas sites.

Dual Ethernet ports (10/100 + Gigabit) – perfect for segmented OT/IT networks and multi-device connectivity.

Allows isolated SCADA networks, IIoT networks, and PLC/RTU connections without external switches.

Multiple serial interfaces: (2) RS-232/RS-485 ports + CANbus – smooth integration with legacy Oil & Gas equipment.

Similarly, it supports flow computers, RTUs, PLCs, and metering systems commonly used in upstream and midstream operations.

Built-in IIoT connectivity: MQTT, OPC UA, SQL database logging, and secure remote access.

Enables real-time monitoring, cloud dashboards, SCADA integration, and remote troubleshooting.

High-performance quad-core processor runs HMI applications and soft-PLC logic simultaneously.

As a result, it reduces panel hardware, simplifies design, and improves local automation capability.

USB host and expansion support adds Wi-Fi, data export, and external device connectivity.

Flexible options for field technicians, data backups, and wireless communication.

Durable industrial construction with strong EMI immunity dependable in high-interference Oil & Gas sites.

Ensures reliable operation near pumps, motors, VFDs, and compressors.

15″ Widescreen HMI

cMT2158Xv2

Class 1 Division 2 (C1D2) certified – approved for hazardous Oil & Gas environments where flammable gases and vapors may be present.

Perfect for well pads, compressor stations, midstream facilities, and refinery process areas requiring certified equipment.

15″ widescreen touchscreen (1024 × 768 resolution) – large, easy-to-read display for detailed process graphics and SCADA-style dashboards.

Ideal for control panels, central valve stations, and operations centers needing maximum screen real estate.

Dual Ethernet ports (10/100 + Gigabit) – supports network segmentation, SCADA connectivity, and secure OT/IT architectures.

Allows PLC/RTU networks to stay isolated while enabling cloud, historian, or remote monitoring connections.

Multiple serial interfaces: 2× RS-232/RS-485 ports – integrates seamlessly with legacy Oil & Gas equipment.

Supports RTUs, flow computers, controllers, LACT units, tank-level devices, and metering systems without external converters.

Built-in IIoT capabilities: MQTT, Sparkplug B, VNC/WebView remote access – ready for modern digital Oil & Gas operations.

Enables real-time production data, alarm reporting, predictive maintenance, and remote SCADA connectivity.

Rugged aluminum enclosure with IP66 / NEMA 4 front panel protection – built for harsh and dirty field environments.

Resists dust, moisture, washdowns, and tough outdoor conditions commonly encountered at Oil & Gas sites.

Fanless solid-state design with high EMI immunity – reliable operation near pumps, motors, VFDs, and high-noise electrical systems.

Minimizes downtime, reduces maintenance needs, and improves long-term field reliability.

Powerful quad-core processor with advanced HMI performance – supports complex graphics, large projects, and fast data handling.

Ideal for multi-screen projects, real-time trending, and high-speed data polling in demanding environments.

7″ Standard HMI

HMI5070L/HMI5070LB

Class 1 Division 2 (C1D2) certified — engineered for hazardous environments common in Oil & Gas operations.

Suitable for field panels and remote locations where flammable gases or vapors may be present.

7″ 800 × 480 pixel resolution display – compact and clear for control panels and remote field installations.

Allows essential process monitoring in tight-space enclosures or small operator stations.

Rugged industrial HMI design with Ethernet, 2 serial ports, – supports connectivity with legacy and modern field equipment.

Includes 1× 10/100 Base-T Ethernet, RS-232, RS-485, and a USB host for data export.

Charcoal/light-grey industrial finish and durable build – designed for harsh field environments and industrial use.

Ideal for sites with rugged conditions, dust, vibration, and moderate exposure.

Solid-state design with industrial interfaces – built for reliability in demanding operational settings.

Reduces downtime and supports long-term, low-maintenance field performance.

Next Steps

The right HMI can greatly improve reliability, safety, and data access in Oil & Gas operations. Maple Systems’ C1D2-certified HMIs provide a durable, future-ready platform for both traditional control and IIoT applications. With multi-protocol support, remote access, edge processing, and rugged design, operators can streamline systems and modernize their infrastructure cost-effectively.

Learn More with Maple Systems

Whether building complex industrial networks or programming your first PLC or HMI, Maple Systems has an expansive library of technical and educational resources to support your success. Explore our support pages for tutorials, technical notes, sample projects, and more.

Contact us

Contact our sales team for pricing, availability, and support.

Email [email protected] or call (425) 745-3229.

About the Author