Your cart is currently empty!

Micro PLC

Micro PLCs are compact logic controllers for small-scale applications that require less than 36 Inputs and Outputs and are extremely cost effective. These controllers provide high-level performance and reliability for industrial automation applications and use our free PLC programming software which utilizes easy-to-use Ladder Logic, Function Blocks, Instruction Lists, or other functions to fit your application. With advanced built-in features such as PID control, high speed counter (HSC), input filtering, and periodic interrupts, these PLCs will work for almost any project. They are DIN rail mountable and come with a variety of digital and analog configurations. Our PLCs easily communicate with our HMIs using MODBUS TCP/RTU making it easy to integrate with the rest of your equipment.

If you need more than 36 I/O points for larger projects, or require Temperature Inputs, see our Expandable PLC products.

Results

-

16-channel Micro PLC

PLC-FB0808P- 8 Bi-Directional Digital Inputs / 8 Digital Outputs

- Serial or Ethernet Communication, Real Time Clock (RTC)

- 2 High Speed Counter (HSC) Inputs – up to 20kHz

- 2 Pulse Train Output (PTO) Channels – up to 100KHz

- PID control, 32 Loops with Auto-Tuning

- Diagnostic LEDs, Built in flash memory

$220.00Quantity Discounts Available -

36-channel Micro PLC

PLC-FB1616P0202- 16 Bi-Directional Digital Inputs, 16 Digital Outputs

- 2 Analog Inputs, 2 Analog Outputs

- 2 High Speed Counter (HSC) Inputs – up to 20kHz

- 2 Pulse Train Output (PTO) Channels – up to 100KHz

- Serial or Ethernet Communication, Real Time Clock (RTC)

- PID Control, 32 Loops with Auto-tuning

- Diagnostic LEDs, Built in flash memory

$320.00Quantity Discounts Available -

36-channel Micro PLC Relay

PLC-FB1616R0202- 16 Bi-Directional Digital Inputs, 16 Relay Digital Outputs

- 2 Analog Inputs, 2 Analog Outputs

- 2 High Speed Counter (HSC) Inputs – up to 20kHz

- Serial or Ethernet Communication, Real Time Clock (RTC)

- PID control, 32 Loops with Auto-tuning

- Diagnostic LEDs, Built in flash memory

$320.00Quantity Discounts Available -

PLC Training

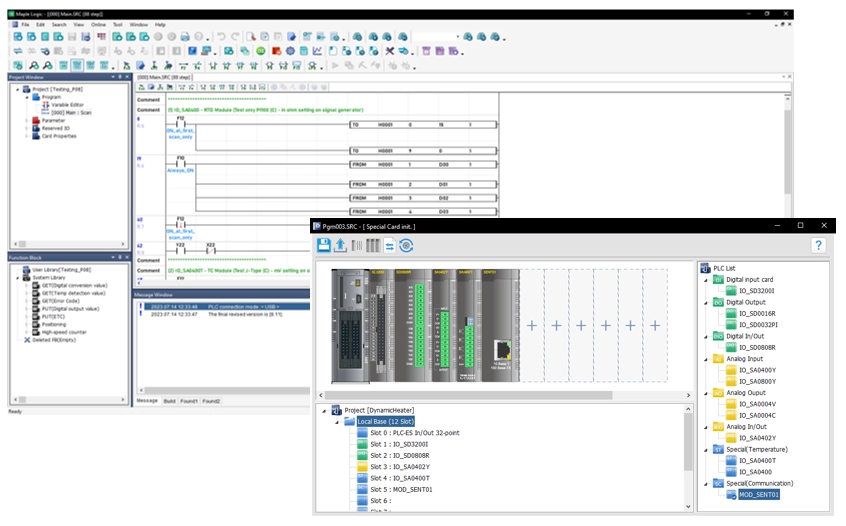

Are you new to PLC programming or do you need more support with our PLC programming software (MapleLogic)? Our catalog of tutorials, sample PLC projects, and tech notes were created to help you learn the tools needed to solve various control problems.

Get introduced to the tools, programming, and hardware used throughout the automation industry. Work alongside our tutorial videos to learn the basics of PLC hardware and PLC software while becoming more proficient in programming by creating your own solutions to common automation problems and testing them in our PLC simulator without the need to have physical hardware.

Skills you will gain: How to wire your input and output devices, configure your PLC, and how to read and write to a register.

Skills you will gain: Understanding of various timers, how to implement timers, and when certain timers should be used.

Skills you will gain: What data types are available, how to address memory, and simple ladder logic.

View our entire training material. Learn how to use, troubleshoot, and create automation solutions.

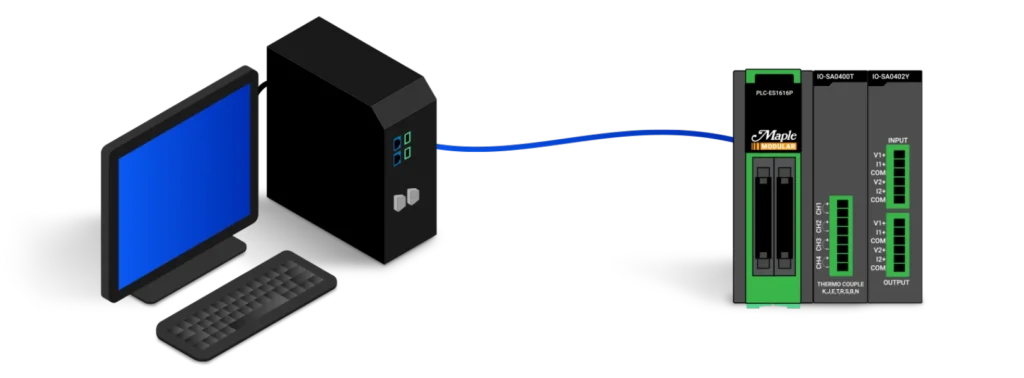

PLC Communication

Our PLCs can function seamlessly as both native slave and master devices through Modbus RTU and TCP/IP protocols. This flexibility simplifies the setup process, automatically assigning Modbus addresses to device addresses, reducing configuration errors and time.

To establish communication, connect your device, configure the channel to reference our PLC, and specify the Modbus address. You can easily verify communication status, or PLC connection, using the diagnostic LEDs located on the front panel of our PLCs.

Available Protocols

- Communicate over Etherent (10/100 Mbps): Modbus TCP/IP Slave

- Communicate over Serial RS-232: Modbus RTU Master and Slave

- Communicate over serial RS-485: Modbus RTU Master and Slave, multi-drop available (up to 32 devices), resistance switch option to improve communication quality

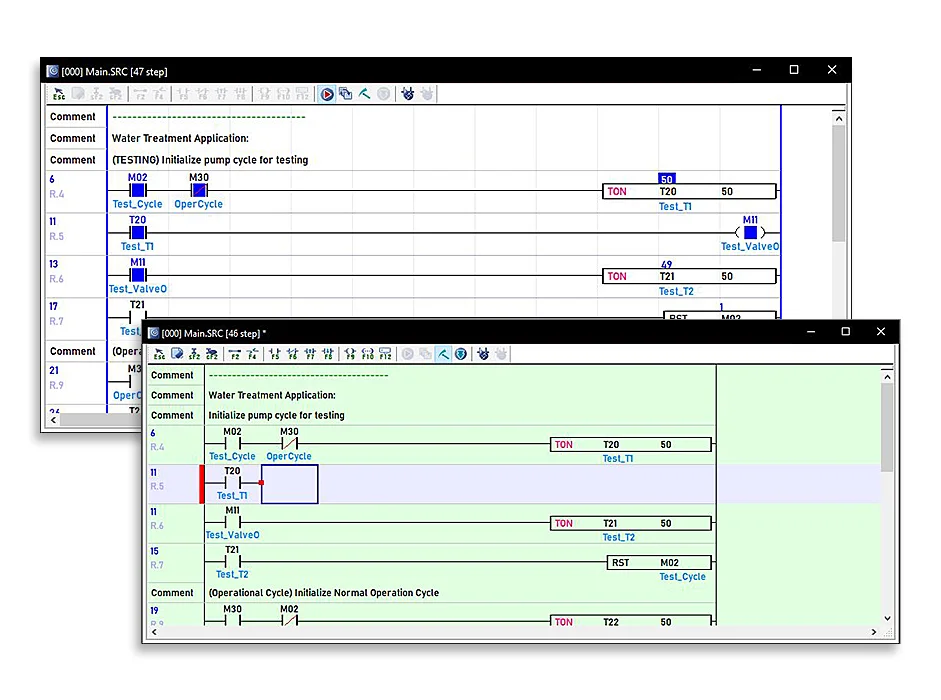

Online PLC Editing

With our PLC software, you have the convenience of making real-time online edits to your logic without ever disconnecting from your PLC device.

Online editing offers several other valuable benefits, such as:

- Reduced Downtime: Perform updates and modifications to your control system quickly, minimizing downtime and ensuring continuous operation

- Rapid Troubleshooting: Quickly diagnose and rectify issues by making immediate changes to the logic during testing and production runs.

- Efficient Maintenance: Simplify routine maintenance tasks by fine-tuning logic and parameters without disrupting the overall system.

This powerful capability not only streamlines your programming and testing but also complements our hardware and software fault detection features.

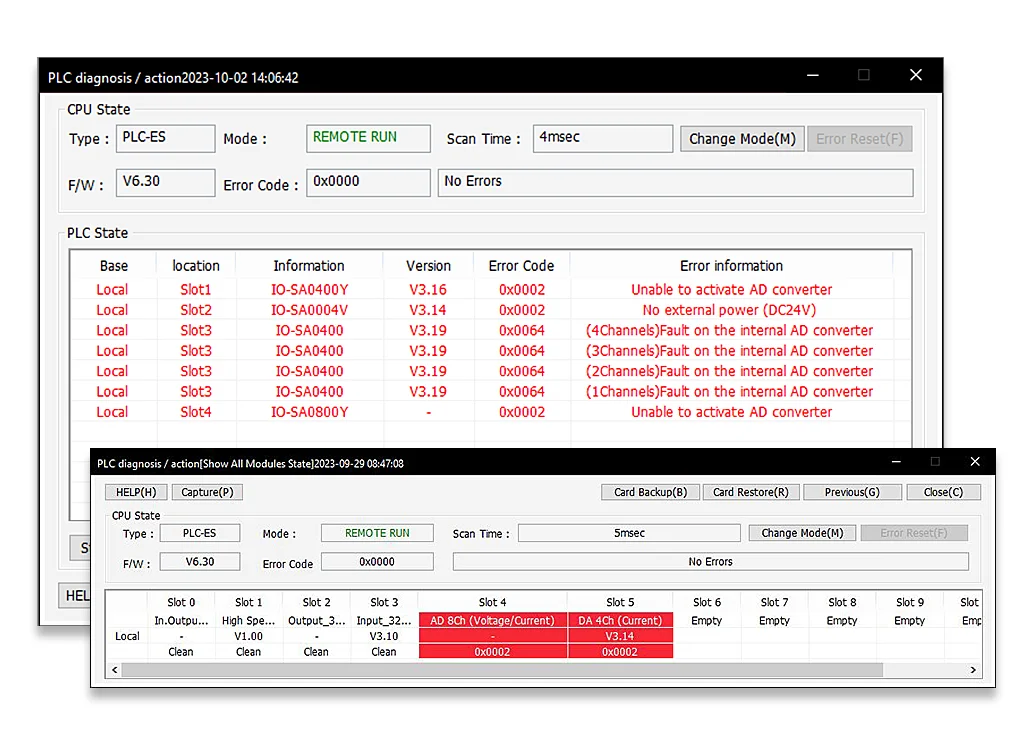

Hardware and Software Diagnosis

MapleLogic provides detailed fault and error detection, ensuring that in the event of an error, you can swiftly identify issues within your device. Detailed information is displayed about the location of the error, whether there’s an error with the PLC CPU and/or the modules, we offer guidance on potential resolutions.

We have also compiled extensive error code tables in our help file, covering general errors and module-specific lists to aid you in your testing phase.

At Maple Systems, we provide free U.S Technical Support, ensuring you have all the diagnostic resources and help to create your unique industrial solution. Feel free to call our Technical Support Team at (425) 745-3229 available Monday – Friday from 6:00AM to 4:30PM PST.

Software

Our software further enhances your troubleshooting capabilities through a dedicated diagnostics window, where error codes and their associated reasons are displayed. If you’re using our Modular PLC, all attached modules are listed with any associated error codes.

Hardware

The front panel of each device features diagnostic LEDs that will indicate anytime there is an error. Special modules also have various speeds of LED blinking corresponding to different errors.