Oil & Gas Industry

Class I Division 2 | Extended Operating Temps | Sunlight Readable

Oil and gas companies around the globe rely on Maple Systems products to help ensure uninterrupted production of critical resources. Whether you are designing for a new application or updating an existing one, Maple Systems offers industrial automation and networking solutions, including Google analytics integration that provide the connectivity, monitoring and control required to get the job done. From pipeline and wellhead monitoring to platform automation, hydraulic fracturing rigs and compressor station control, our industrial automation and networking solutions offer connectivity, monitoring and control across many oil and gas applications.

HMIs for Oil & Gas: Multi-Protocol Integration Without External Converters

Table of Contents

Oil & Gas Companies Partner With Maple Systems

Schedule a call with one of our Technical Sales Representatives. We would love the opportunity to talk with you about how we can help.

Some of the Oil & Gas companies that trust Maple Systems

Class I, Division 2 Rated Products for Oil & Gas Companies

At Maple Systems, we have a wide selection of Class I, Division 2 rated products designed to give you confidence in even the most demanding environments. From HMIs and Web HMIs to Industrial Panel PCs, Box PCs, HMI+PLC Combo Units, and rugged Industrial Monitors, our solutions combine safety, reliability, and performance.

Human Machine Interface (HMIs)

Choose one of our CID2 rated touchscreen HMI displays of 7”, 10”, and 15”. Our industry-leading HMIs features include Capacitive Touchscreens, Wi-Fi, Dual Ethernet, Remote Access, IIoT protocols such as MQTT, Ignition, SparkPlug B , and more. Integrate your ABB TotalFlow, ROC800, ControlWave, and over 400 other PLC and controllers easily with our free configuration software, EBPro.

HTML Web HMI

Web HMIs provide a streamlined alternative to the traditional operator interface. Choose from 4.3″ 7″ and 10.1″ capacitive or resistive touchscreen. As client-only devices, Web HMIs are designed to connect and interact with web-based applications running on a server. No program installations and reduced wiring requirements mean that Web HMIs can be easily added into an existing Class I, Division 2 control system without the need for extensive programming or configuration.

Industrial Panel PCs and Industrial Box PCs

Our CID2 Industrial PCs come with a Windows® Operating System installed that can operate any Windows® Software, powerful SCADA software such as Allen-Bradley’s FactoryTalk® View, Ignition™, AVEVA™ Edge and Wonderware®, or configure them using programming languages such as Visual Basic, Python and C++, providing you with flexible options. Choose from a 15”, 19” or 21” display, or no display at all, to meet your environment and application needs.

HMI+PLC Combo Units

Utilized worldwide to employ diverse applications, our HMI+PLCs lower costs, save space, and feature options including: Serial and Ethernet communication, support for Class I Division 2 installations, and numerous I/O configurations. Programmed using our Free HMI+PLC software MAPware-7000, you get access to graphs, alarms, trending, data logging, web server functionality and more, providing an affordable combination of display and control in a single package.

Industrial Monitors

Our C1D2 Monitors are designed to withstand prolonged shock & vibration, a wide temperature range, and protection from water and dust. With a stainless steel enclosure and high-brightness/sunlight readable 1000 nit projected capacitive touchscreen, this extended temperature, Class 1, Division 2 Industrial Monitor is a great value. ATEX rated. Pair with our C1D2 Box PC.

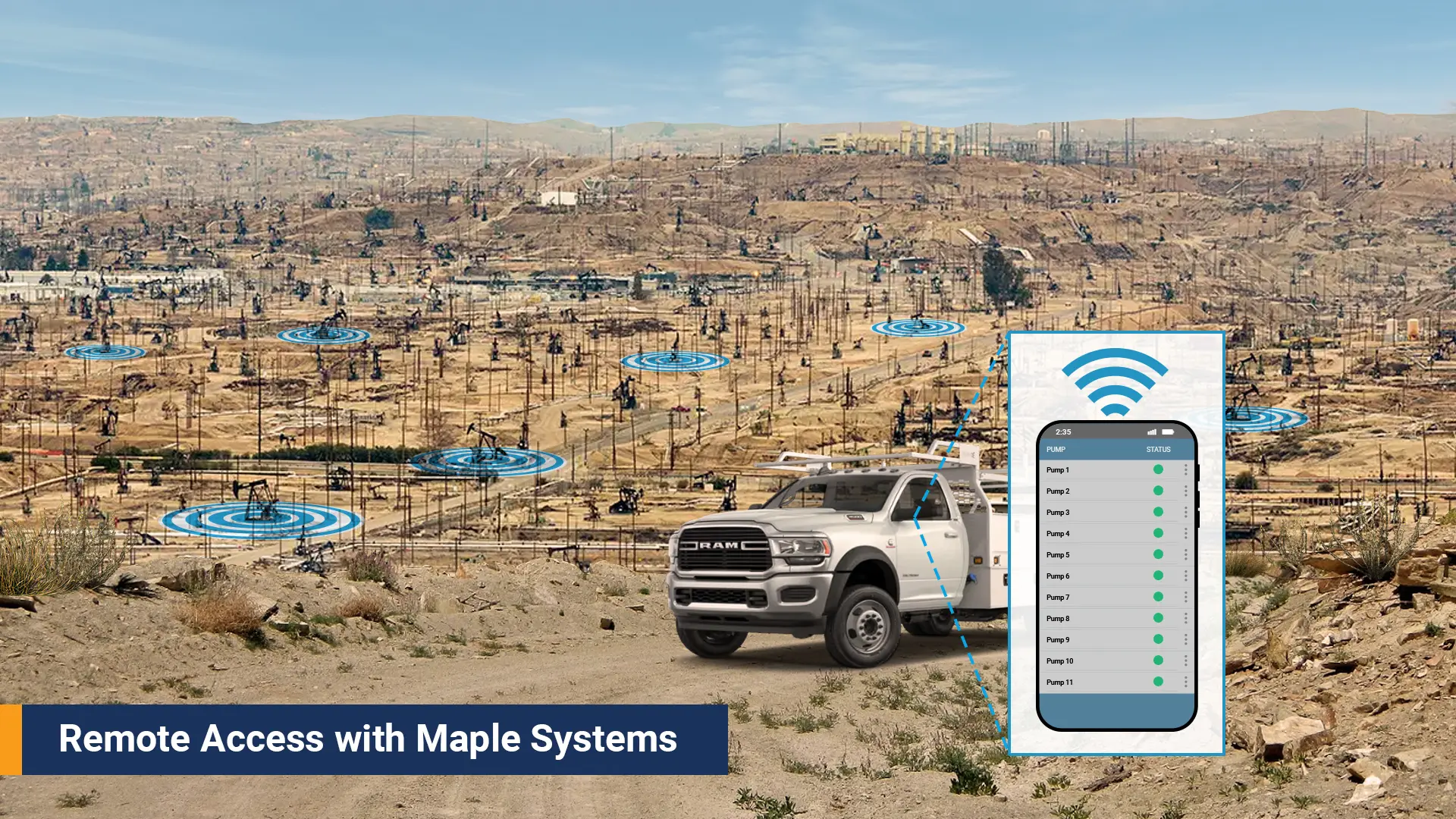

Remote Access

Remote access allows you to reach an HMI or connected device anytime, from anywhere. With our EBPro HMI configuration software and supported hardware solutions, you can connect to an HMI or Gateway device from a tablet, smartphone, or PC. As a result, you can view all data and applications and control the system as if you were standing in front of it.

We have several remote access solutions and each one is different, but generally, all work in similar ways. Keep in mind that each remote access solution will work slightly differently and have their own set of features. Depending on your specific situation, there may be several remote access solution that will work, only you can decide what is best for your specific situation.

EasyAccess2.0

EasyAccess2.0 is a secure access utility that enables remote access to Maple Systems’ HMI and cMT Series devices. View and control any remote HMI with EasyAccess 2.0 from a PC or mobile device, allowing you to resolve issues immediately as they arise from anywhere in the world.

- Control your remote HMIs as though you’re standing in front of them.

- Upload/Download projects to modify and test your HMI Programs.

- Interact with connected PLCs using the PLC Passthrough mode.

cMT Viewer

cMT Viewer is remote connection software built into our EBPro HMI configuration platform. It works with select Maple Systems IIoT-ready HMIs and can run on PCs, Panel PCs, iPads, and Android tablets. Also, with cMT Viewer, you can easily monitor and manage your devices from anywhere.

Key benefits include:

- Free download for quick setup

- Monitor up to 50 HMIs simultaneously

- Faster connections with less bandwidth (only application data is exchanged)

To learn more, read our article What is cMT Viewer?

WebView

WebView enables you to point your browser to the supported HMI’s IP address on your local network and log in. Now you have access to all the functions, data, and project screens from your HMI application. You can access system settings, navigate to any window, and fully control your HMI from anywhere. It works just like VNC, but without requiring you to download or install any additional software!

VNC

VNC (Virtual Network Computing) server is built in on all our HMIs. Any third party VNC viewer client can log into a Maple HMI to see and control exactly what’s shown on the HMI screen. Configurable options on the Maple HMI include: set a password, enable monitor mode (view only – no control), allow single connection or multiple connections.

Online Technical Resources

We’ve compiled our most common technical support topics in one place to help you find the answers you need. From hardware to software, and everything in between, we’ve got you covered.

- Free Software Downloads & Upgrades – Download full versions of our HMI (EBPro) or HMI+PLC (MAPware-7000) configuration software for FREE; access demo versions of our SCADA software, Aveva Edge; and find legacy software versions anytime.

- Manuals & Guides – Our Manuals and Guides help you learn more about our products. We have Operation Manuals, Programming Manuals, and Quick Start Guides on a variety of products and functionality.

- Controller Information Sheets – Maple Systems offers support of more than 400 controller protocols for our HMI series. Controller Information sheets provide instructions and settings for each protocol, allowing your Maple Systems product to communicate with a specific Controller, including Allen-Bradley, Siemens, Omron, Idec, and many more.

- Video Center – We’ve compiled all of our most useful How-To’s, Troubleshooting, Webinar videos into convenient playlists. Choose the playlist you’d like to view below, and watch from start to finish in our video player.

- Tutorials – Browse our list of tutorials for the task you’re looking for, (or use the search function). Quickly grasp the user-friendly features of our different software programs. Follow step-by-step tutorials to guide you through the process seamlessly.

- Sample Projects – We have created sample applications/projects and sample kits that demonstrate software features, give programming information for specific controllers, or demonstrate product capabilities.

- Controller/Communication Cables – We offer hundreds of custom communication cable drawings for the industry’s most popular PLC manufacturers. Whether you want to build your own cable or have us build it for you, we can provide you with exactly what you need.

- Technical Notes – Find documentation for PLC connectivity, email, setting IP addresses, alarms, recipes, macros, and more.

- Solutions – Our Case Studies and Application Stories show real-life applications and how Maple Systems can help improve your company’s bottom-line. Read articles on key software features, connecting current or legacy systems to the IIoT, and improving how you collect, analyze, and manage data.

Free U.S. Based Support

If you weren’t able to find answers in our Support Center, you can ask a product or service-related question by:

- Opening a case with our Technical Support by using our online Case Logger. From this page, enter as much information as possible and a member of our Technical Support team will contact you within 2 business days.

- Reaching out to our Sales team. Email us at [email protected] or call 425-745-3229. We are here M-F 6:00am – 4:30pm Pacific Time to answer your questions.

Large In-Stock Inventory

We carry a large inventory, and most models can ship the next business day. Because we are located on the West Coast, we can handle late orders and get you what you need, fast.

Maple Systems offers our customers the ability to place Blanket Purchase Orders to better manage your inventory and cash flow. Additionally, this strategy helps our production team guarantee we can meet your delivery needs.

Flexible Pricing Structure

Our tiered pricing structure gives customers the most flexibility in purchasing. We will work with you to determine available discounts and maintain pricing from order-to-order regardless of order size.

Call 425-745-3229 or email our Sales team at [email protected] for a quote today

Built-In Industry Drivers for Oil & Gas Companies

One of the advantages of our free programming software, EBPro, is its extensive library of built-in drivers, including support for popular industry PLCs and RTU controllers:

- ABB TotalFlow

- Emerson ROC800

- ControlWave

- Rockwell Ethernet/IP

Our extensive HMI software driver library proved especially valuable for a systems integrator based in Midland, Texas, working on a TotalFlow Meter Run application.

By using one of our CID2-certified HMIs, the integrator was able to quickly develop their project in EBPro. Once their project was complete, they sent it back to us where we created a custom part number for them and retained their project.

When an order was placed for this custom part number, the HMI shipped fully configured and ready to go. On arrival, all the customer had to do was mount it, apply power, and they were back up and running—with no additional setup or programming required.

This is just one example of how our built-in driver support and customer-focused workflow simplify deployment and reduce downtime in the field.

Read our article HMIs for Oil & Gas: Multi-Protocol Integration Without External Converters to learn more about how a Maple Systems HMI can connect directly to PLCs and field devices without additional gateway hardware – thereby simplifying integration, reducing project costs, and ensuring fast, real-time monitoring across pipelines, refineries, well pads, and offshore platforms

Try Before You Buy

We offer multiple ways for you to test and learn our FREE software before you buy any hardware. After downloading the software, walk through the tutorials, watch our videos, use the sample projects, or even attend a webinar.

- Try our HMI Configuration (EBPro) Software – Download, Connect, Run Simulation. Check out our article as we walk you through downloading the software, creating a project, and run the project with offline and/or online simulation.

- Try HMI+PLC Combo (MAPware) Software – Quickly grasp the user-friendly features of MAPware-7000, by following step-by-step tutorials to guide you through the process seamlessly.

- Try SCADA (Aveva Edge) Software – The AVEVA™ Edge demo will run in “Evaluation Mode” for 40 hours before requiring you to purchase a license. It demonstrates the full capabilities of the software.

Now that you’ve explored the software, we can provide you a demo unit for testing potential applications, or to use in an evaluation. Demo units are available for up to 30 days. Contact our sales team for more information on a demo unit.

Oil & Gas Case Studies

At Maple Systems, we’ve partnered with customers across industries to deliver automation solutions that solve real-world challenges. From LACT Skids for custody transfer and remote access systems, to tank battery monitoring, injection well control, meter runs, and water & wastewater control panels, our technology is trusted in the field.

LACT Skid – Custody Transfer

An Integrator in Pecos, TX uses our C1D2 HMIs on their Lease Automatic Custody Transfer (LACT) Skids to sample and measure oil so it can be properly and accurately delivered from the well site to the customer. Our HMI is used to display information regarding the transfer process as well as alert operators and stakeholders of operational issues, such as high water and sediment content. Fail-Safe shutdown and gas detection procedures are also built into the HMI as well as Cloud transmission for remote access.

Remote Access Kit

A Value Added Reseller in Midland, TX created a remote access kit for their end users. The goal was to save both time and cost by reducing the need to send technicians to remote sites for troubleshooting and clearing alarms on skids and pump jacks. To achieve this, the kit included our cMT-SVRX-822, a power supply, and a broadband cellular router mounted just outside the C1D2 area. In addition, it used a C1D2 ethernet cable connected to the PLC within the classified area. With EasyAccess 2.0 preinstalled and activated on the cMT-SVRX-822, customers could log in from home. As a result, they were able to view event logs, check alarm history, clear alarms, and adjust the program preventing future failures.

Tank Batteries

An Integrator in Roswell, NM uses one of our C1D2 HMIs as the eyes into their 5 Tank Batteries. It’s used to view tank levels, control oil flow in and out of the tank, as well as control gas injection at the pumps. Each tank has its own recipe for injection, based on the flow rate, the HMI tells an actuator how much gas is allowed to be pumped into each well, improving the flow of oil into the tanks.

Injection Well Control

An OEM in the Permian Basin uses our 10″ C1D2 HMI to control and monitor the operations of Injection Wells used for disposal of wastewater produced during oil and gas extraction. Our HMI gives the operators an interface to view flow rate, injection volume, and pressure and allows for them to easily make adjustments for efficiency and safety making sure the fluids remain contained, protecting nearby aquafers and there are no unexpected pressure surges.

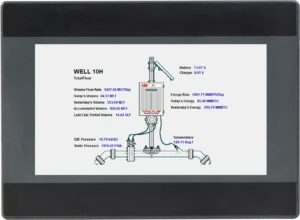

Meter Run

An OEM in Odessa, TX needed a low cost HMI that could communicate to his Emerson ROC800 and view Static Pressure, Differential Pressure, Temperate and Flow values on their Meter Runs. With our free, EBPro Programming software, the Emerson drivers are already built in so our 7″ C1D2 HMI was the perfect solution.

Water & Wastewater Control Panels

GLX Technologies, a systems integrator for small and mid-sized utilities, integrates Maple Systems HMIs into their GLX Connect product line. As a result, the HMIs provide a fully configurable interface for monitoring pumps, tanks, analyzers, and treatment processes without requiring custom PLC programming. In addition, operators can adjust alarms, thresholds, and site configurations directly from the HMI, which reduces engineering time and deployment costs. Consequently, Maple Systems helped GLX deliver scalable, off-the-shelf panels that bring custom-system flexibility at a lower cost.

Customer Service / Warranty

At Maple Systems, providing exceptional customer service is our top priority. As a valued customer, you’ll work with a dedicated Account Manager who knows your business. They are ready to assist with any request: from starting a technical support case and checking order status to locating a missing invoice.

Our online customer portal makes it easy to manage your account anytime. You can view and print sales orders, track shipments, update shipping addresses, and access invoices or our secure payment portal 24/7. In addition, customers with specific permission levels can buy on terms and see established discounts directly on the website. For more details, contact your Account Manager.

Support & Service Resources

- Returns / Repairs

- Warranty Statement

- Start a Support Case

- Contact Sales

- How to Place an Order

- Online Account Benefits

- FAQs

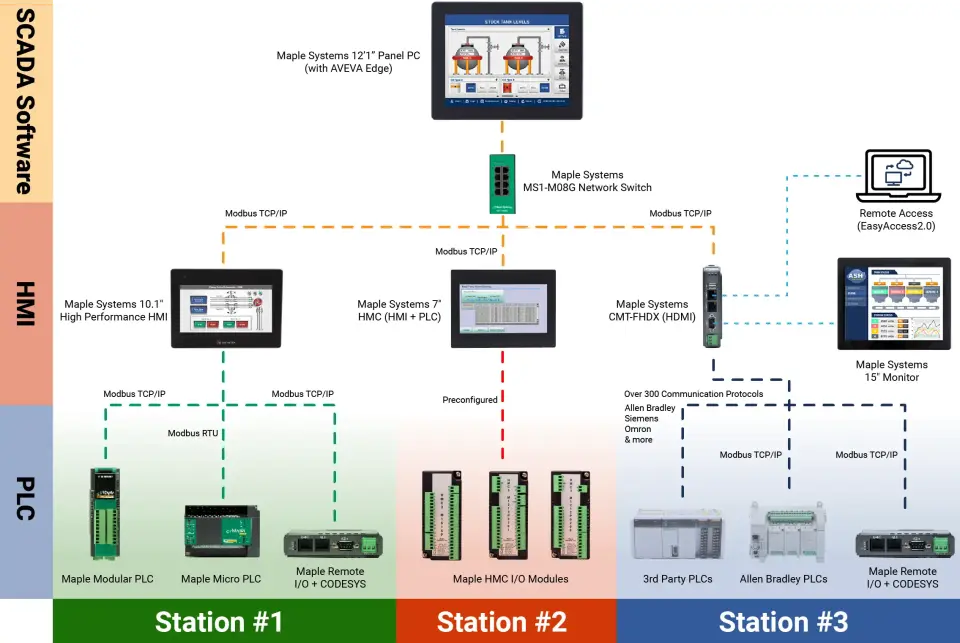

SCADA

Maple Systems offers all the components you need to build your own supervisory data acquisition and control system. This ranges from simple stand-alone machines to sophisticated multi-device networked production lines. In addition, we support enterprise-level operations and IIoT functionalities that leverage cloud connectivity.

- Log data from your devices to aid in reporting, improve efficiency, and reduce downtime.

- Use it to plan routine maintenance with ease.

- Add IIoT functionality such as MQTT, OPC UA, Ignition, SQL database integration, and more.

Our products can help you standardize communications between devices, gluing different systems together for one source to your SCADA. No need to redesign your entire application.

Keep the components that are already working for you, just add Maple Systems components to grow your abilities to supervise, control, and acquire data.

To learn more about how our products work together to create scalable SCADA solutions, visit our SCADA solutions page.