Your cart is currently empty!

PLC Configuration Software Features

Easily create your control projects using our large selection of software features including memory monitoring, auto-tuning, offline simulation, detailed error detection, our fast selection of pre-made instructions and so much more.

- Free full version software

- Quick Start Guides and Video Training Center

- Tutorials on common topics with sample projects

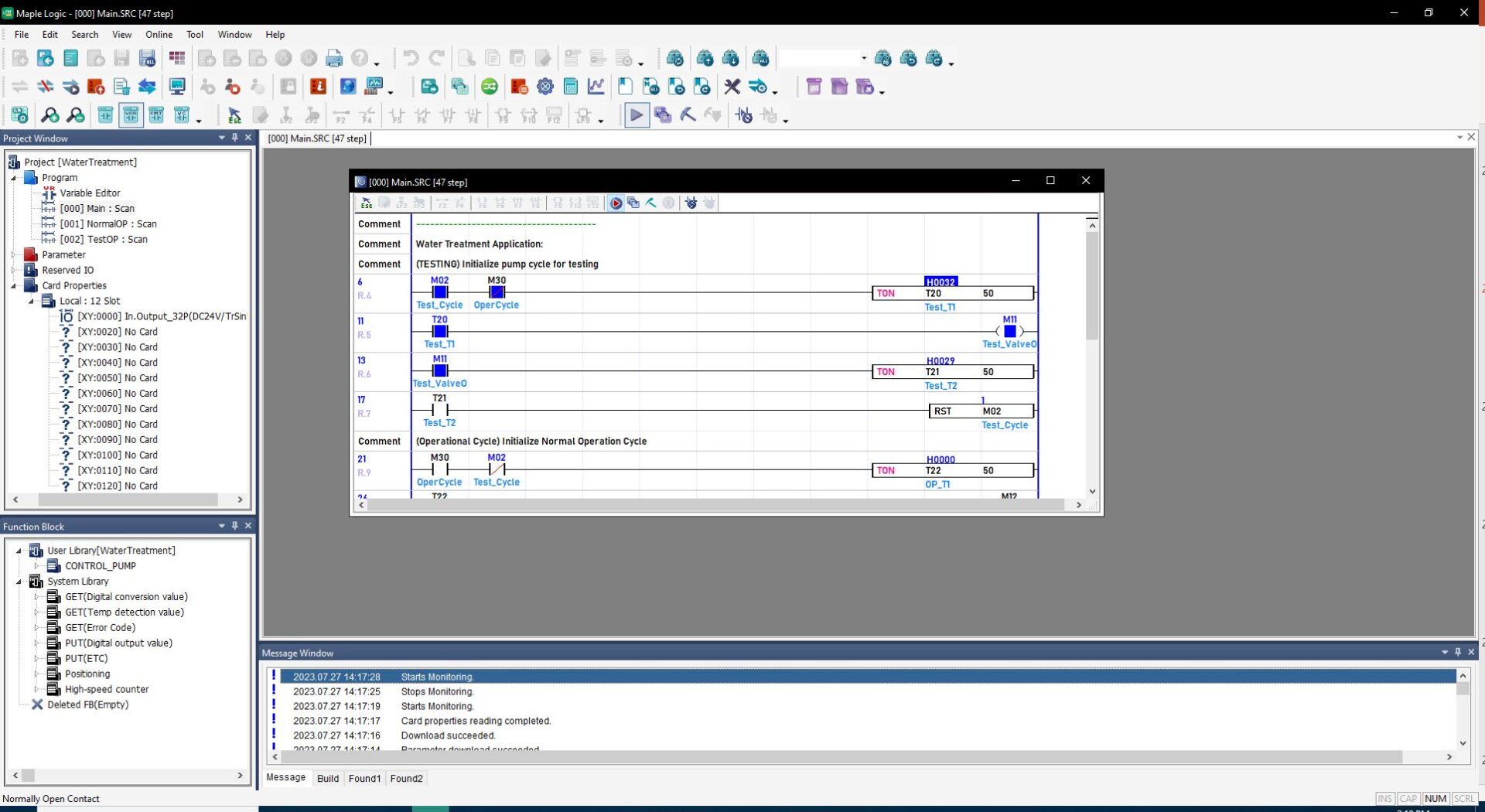

Auto Detection (auto detects modules attached to the PLC CPU and displays them in the Project Window)

MapleLogic has the ability to autodetect modules attached to the PLC CPU. Connecting to a PLC while it is online will show the identified modules connected to the CPU in the Project Window.

Learn more about allocating modules and going online with our “Allocating your I/O Expansion Module and Online Communication” tutorial.

Download our free MapleLogic Programming Software here. Read more about Auto Detection in our MapleLogic Programming Manual.

Built-in Simulator (test and troubleshoot applications before downloading to physical PLC)

Run projects in simulator mode, giving you the ability to test and troubleshoot applications before downloading to the physical PLC. Select the simulator option in the connection settings window and download and link to the simulator.

While using the simulator, you may manipulate register values to simulate operations seen in the field.

Visit our PLC simulator tutorial page to learn how to use the simulator. Follow along to our demo video and download the project to test yourself.

Download our free MapleLogic Programming Software here. Read more about the Built-in-Simulator in our MapleLogic Programming Manual.

Downloadable Device Comments (shows original comments, variable names, & descriptions in addition to the logic when the project is uploaded)

Download project comments to a PLC’s internal memory by selecting the comment option when downloading to a Maple PLC.

This feature has been designed to make troubleshooting and diagnosing errors hassle-free by allowing technicians to upload a project from the PLC to a PC and have the original comments, variable names, and descriptions shown in addition to the logic.

Download our free MapleLogic Programming Software here. Read more about Downloadable Device Comments in our MapleLogic Programming Manual.

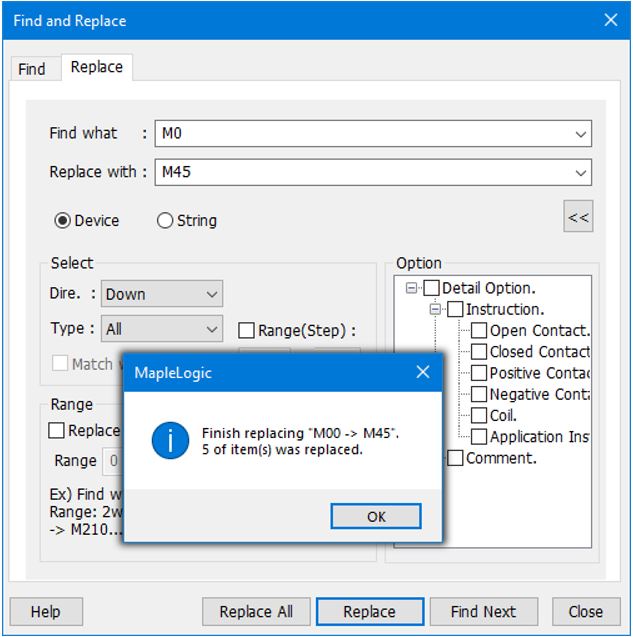

Find and Replace

The find and replace allows users to quickly search for specific registers and strings and replace them if needed. This feature is commonly used to adjust register ranges for consistent organization, fixing any errors, and updating logic.

Find and replace can be used in a program to:

- Find a specific device register (or string)

- Find and replace a single register (or string)

- Find and replace all registers (or strings)

Download our free MapleLogic Programming Software here. Read more about the Find and Replace Feature in our MapleLogic Programming Manual.

Function Blocks

Create customized function blocks to enhance project clarity, implementation across projects, and security. MapleLogic embedded function blocks allow for password protection. This security feature is useful when sending projects between users, while also protecting sections of code from being seen and overwritten by unqualified personnel. Develop function blocks to run custom protocols, perform complex mathematical operations, scale incoming data, and accomplish a myriad of other tasks, simplifying the overall project workflow.

Check out our Tutorials page, Maple Logic Software Overview for more information.

Download our free MapleLogic Programming Software here. Read more about Function Blocks in our MapleLogic Programming Manual.

High-Speed Counter (HSC)

The High-Speed Counter (HSC) program allows users to count the number of pulses received in a high-speed digital input. All our Maple PLCs have two built-in high-speed input channels, with our modular PLC also having a HSC expansion module available.

Our HSC function also includes:

- Pulse Input Type: Single Phase, two-phase, and quadrature available

- Counting Modes: Ring counter mode or linear counting mode

- Preset Value: Used to set up a preset value

- Comparison Mode: Used to compare current value to the comparison value

- Digital Output: Used to indicate if comparison parameters were met

- Pulses Counting Modes: RPM, PPS, and Pulses per Unit Time

To learn more about HSC check out our “How to Program a High Speed Counter” and “What is a High Speed Counter and How is it Used with an Encoder” tutorial pages.

Download our free MapleLogic Programming Software here. Read more about High-Speed Counter in our MapleLogic Programming Manual.

Import and Export Programs, Variables, and Function Blocks

Streamline your project workflow by importing or exporting programs, variables, function blocks, and other settings between projects. This feature allows for the seamless reuse of assets, enhancing overall project efficiency.

Additionally, MapleLogic enables users to export real-time or historical trends that have been recorded while monitoring PLC operations when the system is connected.

Download our free MapleLogic Programming Software here. Read more about these features in our MapleLogic Programming Manual.

Input Filtering (configure filter to eliminate any noise coming from a digital signal, for PLC-ES modules)

The input filtering program allows users to configure the digital input filter for PLC-ES modules. Configure the filter to eliminate any noise coming from a digital signal. Modify both the standard input filter and the user defined filter (from 1-200ms) of any module, and select which inputs use which filter.

Download our free MapleLogic Programming Software here. Read more about Input Filtering in our MapleLogic Programming Manual.

Interrupt Routines (used to halt normal cycles)

The Periodic Interrupt Program allows a program to be executed at intervals specified by the interrupt period. Create up to 15 interrupt programs that are executed at high priority. Use interrupt functions to halt the normal scan cycle until the interrupt program is completed.

Download our free MapleLogic Programming Software here. Read more about Interrupt Routines in our MapleLogic Programming Manual.

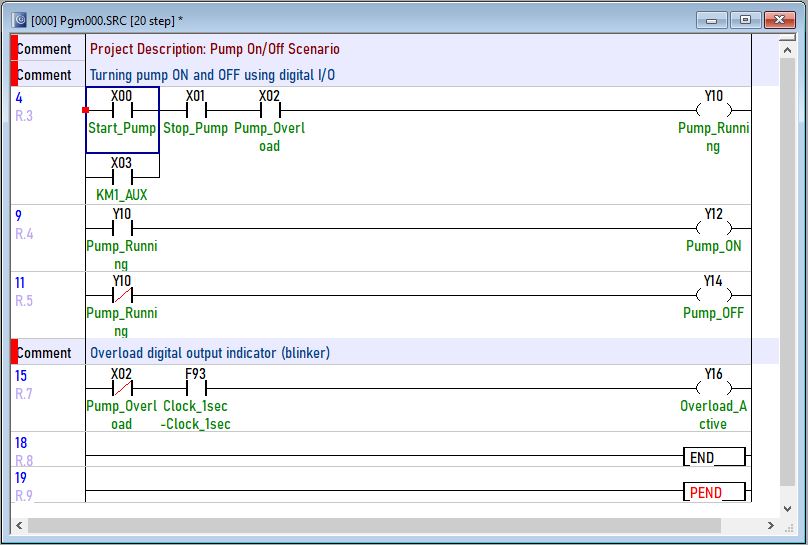

Logic Instructions

Intuitively write your logic by clicking the icons in the instruction toolbar located above the work window. Save additional time by typing out your logic directly onto a rung and using keyboard shortcuts to connect it together all without leaving the keyboard. Our comprehensive help file includes detailed information and examples on instruction use and how they can be implemented in your project.

For more support, check out our tutorial page which includes videos that go through the steps of utilizing different software features.

Download our free MapleLogic Programming Software here. Read more about different logic instructions in our MapleLogic Programming Manual.

Modbus Communication Protocol

MapleLogic makes communicating between devices easy – all our micro and modular PLCs are natively client (slave) devices meaning server (master) devices can simply communicate point-to-point to the predefined register ranges of the PLC via Modbus TCP/IP, Modbus RTU RS-232, and Modbus RTU RS-485.

Visit our tutorial page to learn how to communicate to a PLC, as the slave device, using Modbus RTU and TCP/IP. Our PLCs can also be set up as server (master) devices through serial communication, with our Modular PLC also able to be set up as a Modbus TCP/IP master with an additional communication expansion module, to control devices such as Variable Frequency Drivers (VFDs), remote I/O, and more. Enable automatic transmission of data or control the rate of data exchange with logic.

Visit our tutorial pages to learn how to set up a Maple PLC as a Modbus RTU master and as a Modbus TCP/IP master device.

Download our free MapleLogic Programming Software here. Read more about communications in our MapleLogic Programming Manual.

Online Edit (allows you to edit your project while PLC is still in operation)

Online editing allows users to edit their logic while the PLC is still in operation. This feature makes adjusting logic easier by not requiring the PLC to be taken out of the field which may affect the entire control system.

Simply click connect in the project file and select the “Online-Edit” button above the main program window. Once the logic has been adjusted, click the online edit download button to update the PLC program during run time. This feature is particularly useful during the prototype and testing phase, allowing for quick modifications and streamlining of projects.

To learn more, visit our “How to use the PLC Simulator and Online Edit in Maple Logic” tutorial page. The tutorial page includes a downloadable sample project that can be used to follow along with our written or recorded tutorial.

Download our free MapleLogic Programming Software here. Read more about online editing in our MapleLogic Programming Manual.

PID (with Auto-tuning)

PID (Proportional Integral Derivative) controllers are used to maintain or reach a given target value, such as a desired temperature in a room. Using a feedback system, the PID controller adjusts an output signal.

To learn how to use the PID Auto-tuning feature, refer to our “How to Control the Temperature of a Heater using a PID Loop” tutorial.

Download our free MapleLogic Programming Software here. Read more about PID with Auto-tuning in our MapleLogic Programming Manual.

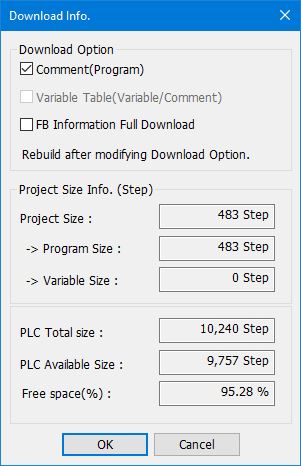

Project Memory Size (displays how much memory has been used and how much free space is available)

The project size of an application is calculated on every download. The download information window displays:

- Steps used in program

- Program and variable step distribution

- Total steps available

- Available steps in percentage

In addition, MapleLogic offers numerous preconfigured F registers that represent CPU Information such as minor and major errors, scan time information, and other indicators useful for troubleshooting and fault detection.

Download our free MapleLogic Programming Software here. Read more this feature in our MapleLogic Programming Manual.

PWM (Pulse Width Modulation)

The Pulse Width Modulation (PWM) program allows users to control the high-speed digital outputs of PWM modules. These digital output signals allow you to control motors, lights, and more.

The PWM special program includes features to control:

- Frequency (pps/Hz)

- Frequency rate change (0-10min)

- Duty Ratio: 0.0-100.0%

- Duty Ratio rate change (0-10min)

Use our PWM GUI to easily modify and test PWM outputs and easily convert to Ladder Diagram for more control.

Check out our Tutorials page to learn more about PWM.

Download our free MapleLogic Programming Software here. Read more about PWM in our MapleLogic Programming Manual.

Real-Time Clock (RTC)

Synchronize the current time of your PLC with your PC in the PLC status window when online with your PLC. The RTC information is used internally to accurately track faults which can be easily accessed through MapleLogic software and can be used in logic.

The Device Monitor window allows for the selection of registers to be monitored, rather than seeing all registers in a data area. Using the auto scan function, all registers used in your program can be easily displayed and monitored while connected to your PLC. Use up to 4 monitor windows to streamline your testing and debugging process. Additionally, this window allows users to edit register descriptions, edit register values, and display registers in various data types (e.g. Float).

Download our free MapleLogic Programming Software here. Read more about RTC in our MapleLogic Programming Manual.

Real-Time Monitoring (monitor your memory addresses in real-time while you’re connected and online with your PLC)

Monitor your memory addresses in real-time with this handy feature that is available while you are connected “online” with your Maple PLC.

Memory Monitor

The Memory Monitor provides an easy tool that can be used to debug your project, open multiple windows, and see the status of all your registers. In addition, the Data Window can also be used to download preset values to the PLC for testing.

The Device Monitor

The Device Monitor window allows for comprehensive monitoring of a program. Using the auto scan functionality all registers used in your program can be easily displayed and managed while connected to your PLC. Use up to 4 monitor windows to streamline your testing and debugging process. Additionally, the device monitor window allows you to:

- Edit descriptions

- Edit values

- Display your registers in either INT, UINT, HEX, FLOAT, or ASCII data types

- Change your register data type

Download our free MapleLogic Programming Software here. Read more about Real-Time Monitoring in our MapleLogic Programming Manual.

Register Database

MapleLogic uses an address-based tag system. Our software provides a large selection of device areas, or data registers, that can be utilized when programming logic. Each data area has a predefined use that allows users to easily keep track of a register’s purpose.

Check out our MapleLogic tutorial video on PLC registers and data types to learn more on how to work with registers.

Download our free MapleLogic Programming Software here. Read more about Register Database in our MapleLogic Programming Manual.

Security Features (Project password, Program password, Function Block password)

MapleLogic allows you to safeguard your project in a multitude of ways:

- Project Password: Ensure users cannot access your entire project without the password

- Program Password: Protect specific programs within your project by only allowing users to access the programs you have determined to be non-critical

- Function Block (FB) passwords: Blocks users from accessing your function block, allowing you to have complex logic equations and formulas without the fear of users accessing and modifying your logic.

In addition, we provide different backup options for projects and programs, giving you the confidence that your projects are secure and can always be accessed by you.

Download our free MapleLogic Programming Software here. Read more about our Security Features in our MapleLogic Programming Manual.

Software Configuration (customize your software to work with your programming style)

Customize your software to work with your programming style

- Adjust how the software behaves on start-up

- Change the visibility of tools and icons

- Alter the look and feel of the Editors

- Create your own hot keys

- Wide selection of Theme settings

- And more!

Download our free MapleLogic Programming Software here. Read more about how to customize your software in our MapleLogic Programming Manual.

Special Programs (streamlines programming of popular functions)

MapleLogic offers a selection of special programs when creating a new program in a project. These special programs streamline the configuration and logic programming of popular functions our PLCs provide. Notable special programs:

- PID Control (auto-tuning available)

- High-Speed Counter (HSC)

- Pulse-Width Modulation (PWM)

Download our free MapleLogic Programming Software here. Read more about this feature in our MapleLogic Programming Manual.

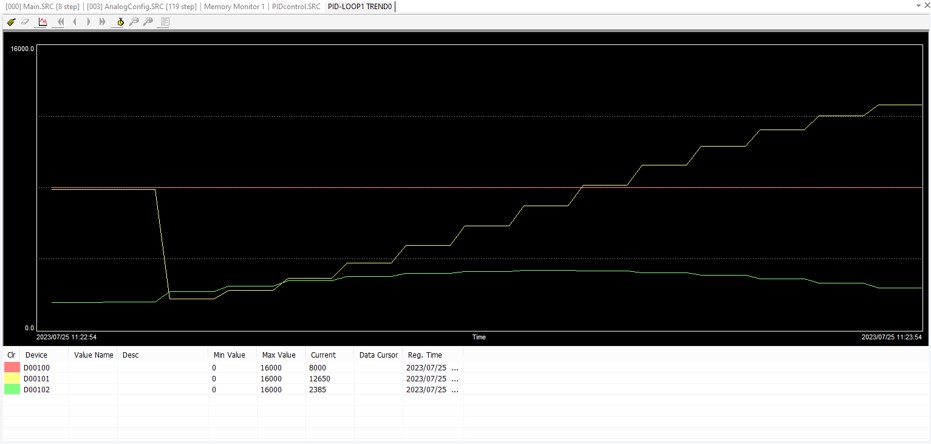

Trend Graphs and Data Analysis

Use the Trend Graph to capture and display real-time or historical trends when connected to a PLC.

- Real-time trend displays data as sampled in real time

- Historical trend displays data over a given time span

- Use both trends to review and save data to an external file

Download our free MapleLogic Programming Software here. Read more about how this feature works in our MapleLogic Programming Manual.

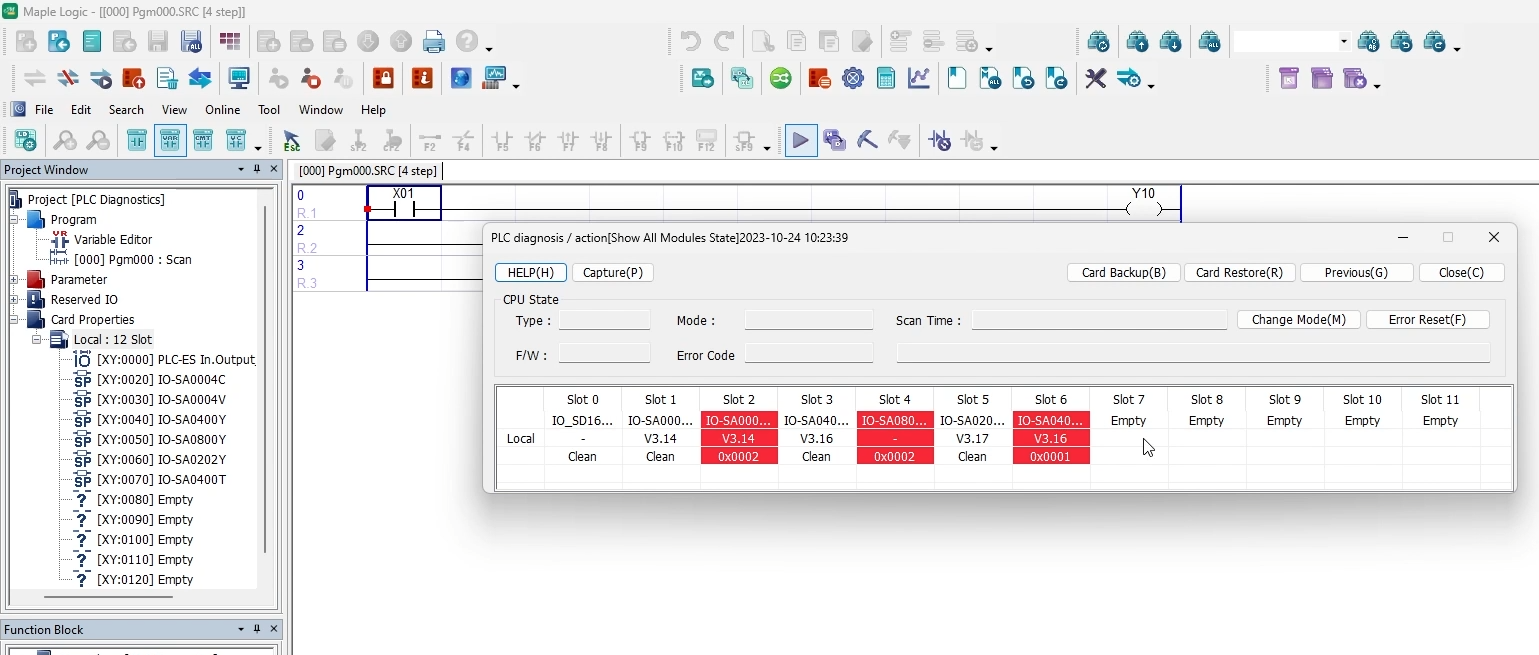

Troubleshooting/Debugging

MapleLogic has a variety of troubleshooting and debugging features to help you create and manage your projects. Detailed information, such as location and possible cause of error, is displayed in the diagnosis window when connected and online with the PLC. When not connected to the PLC, errors can be identified with flashing indicator LEDs on the front panel of the PLC CPUs and modules.

All errors will have a corresponding code and information on the possible reasons for the error. More information and codes can be found in the help file for each module. For additional resources visit our tutorial page on “How to Troubleshoot and Reset Error Codes for your PLC Diagnostics in MapleLogic”.

Download our free MapleLogic Programming Software here. Read more about how these features works in our MapleLogic Programming Manual.

Application Memory Status (displays the memory status of your current project)

The application memory status of your project can be seen on every download.

Information displayed in this window includes:

- Overall Project size in Steps

- Step information for program and variables

- Total Steps available

- Free space on your PLC

In addition, utilize preconfigured F registers, which represent CPU information such as errors and scan times, in your logic to notify you of any major changes in your PLC.

Download our free MapleLogic Programming Software here. Read more about Application Memory Status in our MapleLogic Programming Manual.