Your cart is currently empty!

Alphanumeric OIT Series

Maple Systems Alphanumeric OITs are powerful, affordable operator interface terminals. Our units offer best-in-class features including 2 and 4-line LCD and VFD Displays,16 and 24-key keypads, unique user-definable keypads, and slide-in legends. With the ability to communicate with more than 100 brands of PLCs such as Emerson, GE, Koyo, Mitsubishi, Schneider, and many more; motion controllers, temperature controllers, and embedded microcontrollers, you can easily create the perfect operator interface terminal for your application.

All our OITs operate in temperature extremes ranging from -10˚C up to 65˚C and meets strict Class I, Division 2 and BABA requirements. Made with a rugged aluminum enclosure in the USA, our LCD and VFD OITs are ideal for harsh environments.

Keep reading below to learn more about our Alphanumeric OITs.

LCD Display Models

Great for normal lighting conditions, affordable Backlit LCD OITs are rugged and reliable. They are operable in temperature extremes ranging from -10˚C up to 65˚C. Features include 2 or 4-line Displays, 6 to 24-key keypads, and custom slide-in legends. Class I, Division 2.

OIT3160-B00 • $445.00

2 X 20 Backlit LCD Display, 6 Programmable Keys

OIT3165-A00 • $445.00

2 x 20 Backlit LCD Display, 24 Programmable Keys

OIT3175-A00 • $505.00

4 x 20 Backlit LCD Display, 16 Programmable Keys

OIT3185-A00 • $505.00

4 x 20 Backlit LCD Display, 24 Programmable Keys

VFD Display Models

VFD OITs are useful in situations where a crisp high-contrast Display is desired. The light-emitting Display makes it more readily viewable in low-light environments. They are operable in temperature extremes ranging from -10˚C up to 65˚C. Features include 2 or 4-line Displays, 6 to 24-key keypads, and custom slide-in legends. Class I, Division 2.

OIT4160-B00 • $570.00

2 x 20 VFD, 6 Programmable Keys

OIT4165-A00 • $570.00

2 X 20 VFD, 24 Programmable Keys

OIT4175-A00 • $655.00

4 X 20 VFD, 16 Programmable Keys

OIT4185-A00 • $655.00

4 X 20 VFD, 24 Programmable Keys

More Information about the Alphanumeric OITs

Overview

Alphanumeric OIT

Maple Systems text-based Operator Interface Terminals (OITs) are powerful, affordable solutions for industrial control. Easy to setup and program, OITs offer best-in-class features including two and four-line Backlit LCD and VFD Displays, 16 and 24-key keypads, unique user-definable keypads, and the ability to create custom keypad legends for your application. All Maple OITs are Class I, Division 2 certified and feature a wide operating temperature range of 14 to 149 degrees Fahrenheit (-10 to 65 degrees Celsius).

When programmed with OITware-200 configuration software, Maple OITs can communicate with more than 100 brands of PLCs, motion controllers, servo drives, and temperature controllers.

When programmed with STEPware-100 configuration software, Maple OITs can communicate with an embedded microcontroller or host controller using the ASCII protocol.

Backlit LCD Displays

Vacuum Fluorescent Displays

Maple Systems OITs have three types of standard keypads.

OIT3160/4160 Keypads:

- 3 x 6 = 18 Keys with tactile feedback

- 6 Programmable function Keys (any global or screen dependent function can be assigned to these Keys)

- Tactile-style keypad

OIT3175/4175 Keypads:

- 3 x 6 = 18 Keys with tactile feedback

- 2 x 8 = 16 Programmable Keys (any key function can be assigned to any key location)

- Membrane keypad with non-tactile feedback

- Customizable slide-in key legend insert

- User-generated graphics for keypad

- Free legend generator software available

OIT3165/3185/4165/4185 Keypads:

- 3 x 8 = 24 Programmable Keys (any key function can be assigned to any key location)

- Membrane keypad with non-tactile feedback

- Customizable slide-in key legend insert

- – Free legend generator software available

Maple Systems Alphanumeric OITs can support the monitoring and control of:

- Controllers/PLCs

- Controllers/Motion

- Modbus/ASCII

Certifications

Maple Systems OITs ensure strict compliance with industry standards to provide you with the highest quality product. Our OITs are UL, CE, C1D2, RoHS, & BABA certified to ensure strict compliance with industry standards.

CE Compliance

The CE mark indicates the OIT has met stringent standards for immunity in harsh industrial environments. This standard must be met by all products sold in the European marketplace, meaning that Maple Systems OITS can be sold in European countries.

UL Listed

Underwriters Laboratories, Inc. is the oldest and most recognizable product safety-testing laboratory in the United States. Components recognized by UL have passed safety testing and meet nationally and internationally recognized standards for product safety.

Representative samples of this OIT have been evaluated by UL and meet applicable UL requirements for use in Class I, Division 2 locations, Groups A,B,C,D or non-hazardous locations.

OIT Backlit LCD Displays

Operating in normal lighting conditions? Choose an LED Backlit Liquid Crystal Display (LCD).

Key highlights of Maple Backlit LCD OITs include:

- High contrast LED Backlit LCD (Liquid Crystal Display)

- Viewing angle: Approximately 90 degrees

- 2 lines of 20 characters or 4 lines of 20 characters

- Character height: 0.19 inches (4.8 mm) (2 x 20 models)

- Character height: 0.16 inches (4.0 mm) (4 x 20 models)

In addition, Maple Systems LCD OITs offer useful benefits and features including:

- Support for 100+ controllers

- Class I, Division 2 rating

- Customizable slide-in key legend inserts

- Up to 24 Programmable function Keys

- Operates in extreme temperatures (14° to 149° F | -10° to 65° C)

- Sturdy metal enclosure

- Easy to use configuration software

OIT VFD Displays

For easier viewing in low light environments, choose a Vacuum Fluorescent Display OIT.

Key highlights of Maple VFD OITs include:

- Vacuum Fluorescent Display (VFD)

- High visibility

- Viewing angle: Approx. 90 degrees

- 2 lines of 20 characters or 4 lines of 20 characters

- Character height: 0.19 inches (4.8 mm) (2 x 20 models)

- Character height: 0.16 inches (4.0 mm) (4 x 20 models)

In addition, Maple Systems VFD OITs offer useful benefits and features including:

- Class I, Division 2 rating

- Customizable slide-in key legend inserts

- Up to 24 Programmable function Keys

- Operates in extreme temperatures (14° to 149° F | -10° to 65° C)

- Sturdy metal enclosure

- Easy to use configuration software

- Support for 100+ controllers

Customizable Keys

Enjoy flexibility with Programmable Custom Keys. Many OITs also offer the option to create custom slide-in legends.

Text Displays with Customizable Keys

Maple Systems OIT series has alphanumeric Displays with membrane-style Keys. Each key is Programmable, allowing you to define a unique keypad to match your specific application. The ability to create a custom key legend insert means you don’t have to pay extra for custom overlays to achieve a custom look.

A wide range of communication drivers are available for OITs, including: Allen-Bradley, Modicon, GE Fanuc, Keyence, Galil, and Bristol Babcock. Over 100 brands of PLCs and motion controllers are supported.

Key highlights:

- 2 or 4 lines by 20 character Displays

- LCD and VFD models

- Membrane-style keypad with custom key legend insert

- User-definable Keys

- Serial RS232/422/485 port

- Recipes and menus

- NEMA 4X, CE, UL certified

- Class I, Division 2 rating

Key Types and Functions

Whether you are designing for one application or many, Maple’s OIT series fits the bill with 500 user-definable screens, 16 or 24 user-definable Keys, and a user-definable keypad legend.

Operational Overview

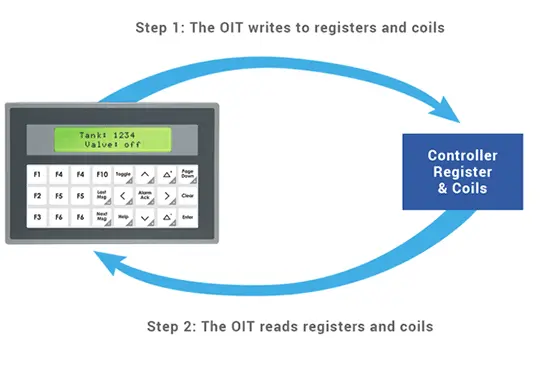

Serial communication allows OITs to read from and write to PLCs and motion controllers.

Maple Systems operator interface terminals communicate with PLCs and motion controllers by using point-to-point serial communications to read from and write to the internal discrete and register memory of the controller. Some of the controller’s discrete and register memory is designated for special purposes: Message Request Register, Current Message Register, Status Bit Coils, and Key Coils.

Message Request Register

The OIT continuously monitors registers in the controller to display correct screens and perform special functions.

The Message Request Register (MRR) is a register in the controller that is continuously monitored by the OIT. When the controller enters a number into this register, the OIT:

- Displays the screen that corresponds to that number

- Performs any special functions associated with the screen

- Optionally sends the screen’s contents to a serial printer.

For example, the system programmer may want Screen #30 to be shown on the OIT whenever input coil X1 is turned on. Screen #30 might say “Oven Door is Open!!!”. The relay ladder logic could be the following:

In this case, D500 is the MRR that the OIT has been configured to poll once every 200 milliseconds. When input coil X1 is activated, the controller puts the decimal number 30 into the MRR. The OIT then sees the number 30 in the MRR and Displays Screen #30.

Current Message Register

The OIT can be programmed to send the number representing the screen currently Displayed on the OIT to a register in the controller called the Current Message Register (CMR). The CMR can be used by the controller to determine which screen is currently being Displayed on the OIT. This might be used to determine which screen in a chained sequence the OIT operator sees.

Status Bits and Key Coils

The OIT uses keypress data to activate coils in the controller to properly display and communicate information.

Status Bit Coils

Status bit coils are a block of discrete coils in the controller used by the OIT to communicate information to the controller.

- Message Received is set by the OIT when a screen request has been successfully retrieved from the controller.

- Invalid Display Message Number is set by the OIT when the controller requests an empty or non-existent screen.

- Message/Keytable Error is set by the OIT when it detects invalid or corrupted data in the screens or key table.

- Message Stack Full and Message Stack Empty are set when the screen stack feature is enabled and the OIT’s internal screen stack is full or empty.

- Reset is set by the OIT each time it powers up or performs a re-initialization due to exiting the OIT’s local setup menu.

- Alarm Stack Full and Alarm Stack Empty are set by the OIT when the OIT’s internal alarm stack is full or empty.

- Clear Alarm is monitored by the OIT to allow the controller to clear the currently Displayed alarm. When the controller sets this coil, the OIT cancels the alarm in progress.

- Clear Alarm Stack is monitored by the OIT to allow the controller to clear the entire stack of alarms including the alarm in progress.

- Acknowledge Alarm is set by the OIT when the operator presses the Alarm Ack key to clear an alarm.

- OIT Pulse is pulsed by the OIT every 10 seconds. This allows the controller to determine if the OIT is still communicating with it.

Key Coils Register

Key Coils are divided into two blocks of discrete coils in the controller: Function Key Coils and Control Key Coils. Key Coils are used to pass keypress data from the OIT to the controller. When a key is pressed, the corresponding coil in the controller is activated. For example, the system programmer wants a motor to run whenever the F1 function key is being pressed by the operator. The relay ladder logic could be:

In this case, internal control relay C389 has been configured as the Function Key Coil for the F1 function key. If the F1 function key has been configured as momentary, then C389 will be activated as long as the F1 function key is being pressed by the operator. Internal control relay C389 is controlling output coil Y33, which is controlling a motor. Consequently, the motor runs whenever the operator is pressing the F1 function key.

Register Monitoring

Easily monitor, display, and update the controller’s discreet and register memory. Includes set points and linear scaling.

The controller’s discrete and register memory can be monitored, displayed, and updated by the OIT. This can be done by configuring the OIT’s screens to display the controller’s discrete and register memory as embedded data fields (register monitors). When the OIT Displays a screen containing a register monitor, the OIT reads the specified memory address in the controller and then displays the data. If the register monitor has been configured as read/write, when the operator changes the data in the register monitor on the OIT’s display the OIT writes the change to the controller’s memory.

Up to 25 read only or read/write register monitors can be displayed in each OIT screen. Each register monitor has:

- Adjustable decimal/symbol location

- Adjustable field width

- High/low limits

- Increment/decrement value

- Left/right justification

- Optional comma insertion

- Optional “hide data” format for secure data entry

- Optional leading zeros

- Read only or read/write

Set Points

Set points are controller memory locations that the OIT monitors. Up to 16 can be active simultaneously. Each set point is configured with a controller memory address to monitor a low and high limit, and OIT screen numbers Display upon low or high limit violation. Set points have a variety of uses: system warnings or alarms, restarting a recipe after a given number of units have been batch processed, or providing the operator with a choice of actions when a trip point has been exceeded.

PLC Integration

PLC Communication

Maple Systems OITs communicate with over 100 controllers and are compatible with most major brand PLCs on the market today.

PLC Manufacturers

Maple Systems OITs are compatible with most major brand PLC manufacturers. Please review the list below.

| PLC Manufacturer | PLC Brands | Protocol |

|---|---|---|

| Acroloop | Motion Controllers | STEPware100 |

| Allen-Bradley (Rockwell Automation) | SLC500 Series PLC 5 Series MicroLogix Series | DF1 Full Duplex (CRC) |

| Animatics | SM172x, 23xx, 34xx, 42xx, and 56xx, and RTC3000 | SmartMotor ASCII |

| Animatics | SM172x, 23xx, 34xx, 42xx, and 56xx, and RTC3000 | SmartMotor ASCII |

| API | Centennial Series, Digital Drive Series, Intelligent Drive (9300), Mini Servo (9400), and Mini Stepper (DM2400) | ISAP |

| Aromat (Panasonic) | FP Series | Computer Link |

| Aromat (Panasonic) | FP Series | Computer Link |

| ASCII Slave | Generic | ASCII (OIT as Slave) |

| Baldor | Mint Drives, Smart Move, and Next Move BX | STEPware100 |

| Bristol Babcock | RTU 3305/3310, DPC3330/3335 | Modbus RTU (OIT as master) |

| Control Microsystems | SCADAPack | Modbus RTU (OIT as master) |

| CTC | Series 2200/2800 | CTC Serial Data |

| Delta | DVP Series | DVP Modbus (OIT as master) |

| Electro-Craft | IQ Series Servos | STEPware100 |

| Emerson | Axima, En Drives, Epsilon | Modbus RTU (OIT as master) |

| Entertron | SK1600, Elite 2000, Smart Pak | Modbus RTU (OIT as master) |

| Fife | CDP-01 | Fife |

| GE Fanuc | Series 90-30/70, Micro, VersaMax | SNP |

| Giddings & Lewis | MMC, PIC controllers | Modbus RTU (OIT as master) |

| Hitachi | H Series | Procedure 1 One-Way |

| Idec | Micro3 and OpenNet | Computer Link 1:1 (ONC) |

| Industrial Control Links | ICL4100/4200/4300 | Modbus RTU (OIT as master) |

| Intelligent Motion | Lynx | STEPware100 |

| Intelligent Parallel Machines | IPM | Modbus RTU (OIT as master) |

| Keyence | KV Series | KV-Mode |

| Koyo (Automation Direct) | DL305 Series | N Sequence (CCM) |

| Koyo (Automation Direct) | DL105, DL205, DL405 Series | K Sequence |

| Mitsubishi | FX Series | Monitor Interface |

| Modbus Generic | Generic | Modbus RTU (OIT as master) |

| Modicon (Schneider Electric) | 984 Series, Compact, Momentum, Micro | Modbus RTU (OIT as master) |

| Motorola | MOSCAD | Modbus RTU (OIT as master) |

| Omron | C Series and CPM1, CPM1, SRM1 | Hostlink |

| Pacific Scientific | PC830 Drives | PC830 |

| Pacific Scientific | Indexer/Drivers 5345, 5445, 5465 | STEPware100 |

| QuickSilver | SilverMax Drives | ASCII |

| SAF | Drives | Modbus RTU (OIT as master) |

| Siemens | S5 Series | Loader Port |

| Siemens | S7-200 Series | PPI |

| SixNet | SixTrak VersaTrak | Sixnet Modbus RTU (OIT as master) |

| Telemecanique | TSX Nano, Quantum Series | Modbus RTU (OIT as master) |

| Texmate | TEX-ICC400/4480 | Modbus RTU (OIT as master) |

| Thomson | TMC2000 | STEPware100 |

| Toshiba | T Series | Programming Port |

| Trio Motion | Motion Coordinator Master | Modbus RTU (OIT as master) |

| Twido (Schneider Electric) | Twido | Modbus RTU (OIT as master) |

| Warner | MX2000, SZ2000, TDC330 | STEPware100 |

| Watlow Electric | CAS200, CLS200, CPC400, MLS300, PPC200 | Modbus RTU (OIT as master) |

| Whedco | Motion Controllers | Modbus RTU (OIT as master) |

| Yaskawa | Magnetek Drives MP Series | Modbus RTU (OIT as master) Memobus |

Serial Communication

Serial Communication enables to OIT to monitor and support a variety of controllers.

The Maple Systems OITs support RS232/422/485 communication, allowing support monitoring and control of:

- PLCs (Programmable Logic Controllers)

- Motion Controllers

- Specialized Controllers

Screens

Convey important information to the operator using various screen types and features.

Type of Screens

Maple Systems OITs allow users to store up to 500 user-definable screens and offer many types of useful screens. These include:

- Message Screens: Convey information to the OIT operator and allow the OIT operator to change data in the controller.

- Recipe Screens: Allow the OIT operator to setup and start a batch process.

- Alarm Screens: Notify the OIT operator of alarm conditions using a message and an audible alert.

- Menu Screens: Allow the OIT operator to branch off to other message, recipe, or menu screens.

- Help Screens: Convey information to the OIT operator specific to the screen being Displayed when the OIT operator presses the HELP key.

| Feature | Message | Recipe | Alarm | Menu | Help |

|---|---|---|---|---|---|

| Blinking Characters | ✔ | ✔ | ✔ | ✔ | ✔ |

| Special Characters | ✔ | ✔ | ✔ | ✔ | ✔ |

| Screen Chain | ✔ | ✔ | |||

| Help Screen | ✔ | ✔ | ✔ | ||

| Horizontal Scrolling | ✔ | ✔ | ✔ | ✔ | |

| Beep on Display | ✔ | ✔ | ✔ | ✔ | |

| Startup Screen | ✔ | ✔ | ✔ | ||

| Timed Display | ✔ | ✔ | ✔ | ||

| Register Monitors | ✔ | ✔ | ✔ | ✔ |

Messages

Easy to read messages provide clear direction for the OIT operator.

- Display up to 25 register monitors

- Convey information to the operator in an easy to read format

- Allow the operator to change data in the controller

- Beep on Display

- Chain to other messages

- Display for a preset duration of 1 to 255 seconds

- Display one line of scrolling text up to 128 characters

Message Display

Messages can be displayed by function keys or by requests from the controller.

Recipes

Easily create, edit, and use recipes for all of your batch processes.

- Operator may set up and start a batch process

- Include up to 20 preset values

- Operator can edit preset values

- Display up to 25 operator controlled values

- Beep on Display

- Display for a preset duration of 1 to 255 seconds

- Display one line of scrolling text up to 126 characters

- Select Recipe Screen

- Edit Recipe/View Presets

- Add Presets

- Gate Coil

- View Presets

- 20 Presets Per Recipe

Download Recipe

With Maple Systems OITs, recipes are easily downloaded to the controller by setting the Initiator to “Y” and pressing the Enter key.

Alarms

Notify the OIT operator regarding alarm conditions and real-time information.

- Inform the operator of alarm conditions

- Display a message using one of 4 priority levels

- Sound one of 9 audible alerts

- Select tones and duration of alarms

- Display up to 25 register monitors

- Provide real-time information

- Display one line of scrolling text up to 128 characters

- Alarm Conditions

- Priority Level

- Alarm Outputs

Alarm Activation

Alarms are activated by the controller using the message request register.

Menus

Operators may easily branch menu screens together to use for longer descriptions.

- Operators may easily branch to a maximum of 9 message, recipe, or menu screens

- Can chain menu screens together for longer descriptions

- With the addition of “timed Display”, menus will auto-scroll vertically

- Menu Selection

- Menu Editor

- Text Editing

Number Keys to Display

With Maple Systems OITs, you can quickly and easily use number keys to display menu screens.

Help Overview

Use the Help feature to provide additional information to aid the OIT operator. With Maple Systems OITs, the help feature can be utilized to:

- Display help screens from any message, recipe, or menu screen

- Provide additional information to assist the OIT operator

- Link to related message, recipe, or menu screens

Help Key

Press the Help key to Display help options.

Keys and Key Legend Inserts

Use OIT Keys to assign functionality. Most units can be customized with keypad legend inserts.

Key Legend Inserts

Maple Systems OIT products offer a key legending feature that gives you a fully customized keyboard easily and affordably. The OIT’s tough polyester overlay provides for a water tight protective insert for any graphics added in the clear window area. Use the Maple supplied insert or create your own.

Create Your Own Custom Key Legend

The key legend insert is exposed when the panel mounted bezel is removed, allowing the insert to easily slide in or out. The clear window lets you change the look of the Function, Numeric, and Control Keys, or designate a location for your logo through simple replacement of the standard Maple Systems insert. Simply remove the Maple supplied insert and replace it with your own custom graphics to customize your keypad to the colors and graphics of your choice.

Once the bezel is replaced, the window is fully water and oil resistant to a NEMA 4/12 rating, so you can even use photocopied materials for your insert. With custom key legending, you can add as many colors as you’d like without incurring additional costs.

Type of Keys

- Global function Keys

- Screen-dependent function Keys

- Numeric Keys (can be combined with Control Keys)

- Control Keys (Page Down, Toggle, Help, etc.)

- Edit Keys

User-Defined Keys

For models with keypad legend inserts:

- Choose according to the number of Keys needed:

- Up to 24 Keys (OIT3165, OIT4165, OIT3185, OIT4185).

- Up to 16 Keys (OIT3175, OIT4175).

- Determine the arrangement of the Keys:

- Any key function can be assigned to any key location.

- Configure the OIT’s keypad:

- OIT configuration software includes an easy-to-use key editor.

- Create your own customizable key legend insert to label the Keys:

- Use Maple’s easy legend generator software.

- User-Defined Key Editor

- Arrangement of Keys

- Defined Key Function

- Configure the OIT’s Keypad

Control Keys

With Maple Systems OITs, control can be separate or combined. Control Keys are programmed as:

- Page Up and Page Down (Move through chained screens)

- Last Msg and Next Msg (Move through stacked screens)

- Help (Display customized help screens)

- Alarm Ack (Acknowledge Displayed alarm messages)

- Arrow Keys (Move cursor between register monitors)

- Delta+ and Delta- Keys (“Jog” register value by a preset amount)

- Toggle (Change the state of the coil/bit)

- Set up (Place the OIT in setup mode)

Global Keys

- Up to 16 global function Keys per keypad

- Each global function key is configured to perform the same function everytime, no matter what screen is Displayed

- Can be programmed as:

- Momentary

- Push On/Push Off

- Latch

- Display Message

- Disabled

- Page Up and Page Down (Move through chained screens)

- Last Msg and Next Msg (Move through stacked screens)

- Help (Display customized help screens)

- Alarm Ack (Acknowledge Displayed alarm messages)

- Arrow Keys (Move cursor between register monitors)

- Delta+ and Delta- Keys (“Jog” register value by a preset amount)

- Toggle (Change the state of the coil/bit)

- Set up (Place the OIT in setup mode)

Function Key Operation

- Function Key Editor

- User-Defined Key Editor

- User-Defined Key Assignment

- Function Key Assignment

Screen-Dependent Function

With Maple Systems OITs, screen-dependent function Keys, or SDF Keys:

- Can be located anywhere on the keypad

- Each performs a single dedicated “default” function, or multiple functions dependent on the message screen

- Can be programmed as:

- Default (global)

- Momentary

- Push On/Push Off

- Latch

- Message Display

- Disabled

- Up to 8 per keypad (6 for OIT3160/OIT4160)

Different Action on Each Screen

Screen-dependent function Keys can perform a different action on each new screen.

- Screen-Dependent Key Editor (1)

- Screen-Dependent Key Editor (2)

- User-Definable Key Assignment

- Screen-Dependent Function Key Editor

- Screen-Dependent Function Key Default

Edit Keys

Maple Systems Edit Keys are programmed as:

- Clear: Clears the current register monitor’s contents and activates data entry mode

- Delete: Performs a destructive backspace at the cursor’s current position in a register monitor

- Enter: Accepts the data entered by the OIT operator and updates the PLC register. In setup mode, accepts the current entry and advances to the next menu.

- User-Defined Key Editor

- User-Definable Key Assignment

Control Registers

The OIT shares and displays information from the controller by activating registers in the controller.

Overview

The OIT family reads from and writes to the controller’s internal registers and coils.

Message Request Register

The Message Request Register (MRR) is a register in the controller that is continuously monitored by the OIT. When the controller enters a number into this register, the OIT:

- Displays the screen that corresponds to that number

- Performs any special functions associated with the screen

- Sends the screen’s contents to a serial printer (optional)

For example, the system programmer may want Screen #30 to be shown on the OIT whenever input coil X1 is turned on. Screen #30 might say “Oven Door is Open.” The relay ladder logic could be the following:

In this case, D500 is the MRR that the OIT has been configured to poll once every 200 milliseconds. When input coil X1 is activated, the controller puts the decimal number 30 into the MRR. The OIT then sees the number 30 in the MRR and Displays Screen #30

Message Request Register Overview 1

Request Display of stored screen Step 1: Controller writes the screen number into the Message Request Register.

Message Request Register Overview 2

Allows the controller to request stored screens for Display on the OIT, using one or multiple Message Request Registers and an optional status coil.

- Message Control Settings

- Message Request Register Options

- Message Request Register (MRR) Editor

- Create New MRR Entry

- Multiple Language Support

Current Message Register

Maple Systems OITs can be programmed to send the number representing the screen currently Displayed on the OIT to a register in the controller called the Current Message Register (CMR). The CMR can be used by the controller to determine which screen is currently being Displayed on the OIT, whether Displayed due to MRR, Set Point Limit, Function Key, etc. This might be used to determine which screen an OIT operator sees in a chained sequence.

- Message Control Settings

- Enable Current Message Register

Status Register

The Status Register allows the controller and OIT to share status information and provide handshaking capabilities for messages, alarms, and errors, etc.

Status Bit Coils and Key Coils

Status bit coils are a block of discrete coils in the controller used by the OIT to communicate information to the controller.

- Message Received is set by the OIT when a screen request has been successfully retrieved from the controller.

- Invalid Display Message Number is set by the OIT when the controller requests an empty or non-existent screen.

- Message/Keytable Error is set by the OIT when it detects invalid or corrupted data in the screens or key table.

- Message Stack Full and Message Stack Empty are set when the screen stack feature is enabled and the OIT’s internal screen stack is full or empty.

- Reset is set by the OIT each time it powers up or performs a re-initialization due to exiting the OIT’s local setup menu.

- Alarm Stack Full and Alarm Stack Empty are set by the OIT when the OIT’s internal alarm stack is full or empty.

- Clear Alarm is monitored by the OIT to allow the controller to clear the currently Displayed alarm. When the controller sets this coil, the OIT cancels the alarm in progress.

- Clear Alarm Stack is monitored by the OIT to allow the controller to clear the entire stack of alarms including the alarm in progress.

- Acknowledge Alarm is set by the OIT when the operator presses the Alarm Ack key to clear an alarm.

- OIT Pulse is pulsed by the OIT every 10 seconds. This allows the controller to determine if the OIT is still communicating with it.

Key Coils

Key Coils are divided into two blocks of discrete coils in the controller: Function key coils and Control key coils. Key coils are used to pass keypress data from the OIT to the controller. When a key is pressed, the corresponding coil in the controller is activated. For example, imagine the system programmer wants a motor to run whenever the F1 function key is being pressed by the operator. The relay ladder logic could be:

In this case, internal control relay C389 has been configured as the Function Key Coil for the F1 function key. If the F1 function key has been configured as momentary, then C389 will be activated as long as the F1 function key is being pressed by the operator. Internal control relay C389 is controlling output coil Y33, which is controlling a motor. Consequently, the motor runs whenever the operator is presses the F1 function key.

- Controller Settings

- Controller Access Settings

Control Keys

Control Keys allow the controller to monitor OIT key presses. Each of these Keys can be separately configured to disable its normal OIT operation, emulating a momentary function key. An OIT can set and clear Control Key coils as the corresponding key is pressed and released.

- Control Key Editor

- Control Key Configuration Data

Set Points

Set points are controller memory locations that the OIT monitors. Set points allow OITs to continuously monitor up to 16 controller registers simultaneously. Each set point is configured with a controller memory address to monitor a low and high limit:

- OIT periodically reads the registers with OIT-assigned set points

- OIT compares value with high and low limits

- If a limit is exceeded, the associated screen is Displayed

Set points have a variety of uses: system warnings or alarms, restarting a recipe after a given number of units have been batch processed, or providing the operator with a choice of actions when a trip point has been exceeded.

- Set Points Editor

- Add To Setpoints List

Register Monitoring

The controller’s discrete and register memory can be monitored, Displayed, and updated by the OIT. This can be done by configuring the OIT’s screens to Display the controller’s discrete and register memory as embedded data fields (register monitors). When the OIT Displays a screen containing a register monitor, the OIT reads the specified memory address in the controller and then Displays the data. If the register monitor has been configured as read/write, when the operator changes the data in the register monitor on the OIT’s Display, the OIT writes the change to the controller’s memory.

The Register monitor allows you to Display and modify controller registers and coils.

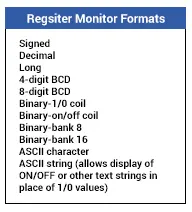

Step 1: The OIT writes to registers and coils

Step 2: The OIT reads registers and coils

Register Monitor Options

Maple Systems OITs enable up to 25 read-only or read/write register monitors to be Displayed in each OIT screen.

In addition, OITs offer many Register Monitor options including:

- Format selection

- Adjustable field width

- Increment/decrement value

- Separator and comma selections and insertions

- Adjustable decimal/symbol location

- Left or right justification

- Leading zero’s selection

- Adjustable offset

- Adjustable low and high limits

- Hidden data entry format for secure data entry

- Read only or Read/Write

- “Blink if bit is set” selection

- ASCII characters and stored strings displayed by register value

- Linear scaling conversion

- Select from 20 presets or define your own

OITs allow controller’s registers and coils to be displayed or modified using Number keys, the Toggle key, and + / – keys.

Register Monitor Option Examples

- PLC Register Monitor

- Set Data

- Read/Write Access

Linear Scaling Presets

Programmable linear scaling is available on the signed, decimal, and long register monitor formats. Linear scaling is the process of converting one unit of measure to another, usually from a machine format to an operator-readable format, so the operator has the data presented in readily understandable terms. A common application involves converting analog or digital data into degrees, speed, voltage, or temperature. If linear scaling is used on a read/write register, the operator can modify the data in the operator-readable format and it will be converted back into the machine format before being sent to the controller.

Software

OITware-200

Alphanumeric OIT configuration software contains powerful features and is easy to use.

Software Overview

Maple Systems latest release of OITware-200 comes with powerful features to make configuring your OIT products more intuitive:

- Multi-language support allows you to configure an OIT with 2, 5, or 10 different languages

- Recipe uploads and downloads can be triggered by either the OIT or the controller

- Remote variable storage function provides greater storage capacity

- Your OIT can be configured as a Modbus slave device

- Expanded support for Allen-Bradley MicroLogix Controllers, including the L data file

- Added support for CTC motion controllers, Yaskawa-Magnetek controllers, and Control Microsystems controllers

Main Feature

- OITware-200 supports all OIT, PLC, and motion controller protocols in a single software package

- Enables easy OIT configuration from a personal computer

- Provides access to all configurable OIT functions and options

- Transfers protocol and application data to the OIT

- Reads application data from the OIT (for a previously configured OIT)

- Offers full Windows® compatibility including menus, commands, and features

Implement It

Follow our five easy steps for setting up your OIT/PLC and first project.

Easy Implementation

Utilizing a Maple Systems OIT is amazingly simple. When your application is ready, just connect the OIT to your PC’s RS-232 port, power up and download. And it’s just as easy to modify your application in the future. Maple Systems configuration software lets you develop your application on any Windows®-based PC. An intuitive interface and user-friendly controls enable you to quickly design screens, layout the keypad, and setup function Keys.

Step 1

Open or create a project in OITware-200.

Step 2

Add a custom keypad legend if desired.

- Use the default keypad legend supplied within your OIT.

- Create a computer-generated keypad legend using the dimensions supplied in the OIT’s installation manual.

- Or, photocopy the blank keypad legend supplied in the OIT’s installation manual and hand illustrate.

- You may also create a full color slide-in keypad legend using Maple’s free

Keypad Legend Generator software.

Step 3

Connect your PC to the OIT using Com 1. If Com 1 is not available, use Com 2.

Step 4

Download Project to the OIT.

- At power-up, press and hold the lower right key until the OIT asks for a setup password.

- After entering setup password, press the lower right key until the OIT’s Display reads: “Computer Comm Mode, Computer must log-on.”

Step 5

Connect the OIT to the Controller.