Food & Beverage Industry

Increase Throughput | Elevate Quality Control | Enhance Traceability

Today’s advanced HMI in food industry applications offers innovative solutions for addressing industrial process control challenges across food and beverage systems. Whether your operation involves sorting, filling, forming, packing, or inspecting products, modern control technology helps you tackle unique manufacturing challenges with precision and reliability. These comprehensive food and beverage systems enable operators to manage multiple production lines from a single interface while improving safety through intelligent alarms and emergency shutdown capabilities. The integration of robust HMI in food industry environments supports companies in meeting stringent regulatory compliance and sanitation requirements through durable, easy-to-clean designs that withstand demanding production conditions. From automated dairy operations to freeze-drying applications and cereal processing equipment, food and beverage systems featuring advanced human-machine interfaces provide the flexibility, performance, and traceability essential for maintaining product quality, enhancing operational efficiency, and ensuring food safety throughout the entire supply chain.

Table of Contents

Food & Beverage OEMs, Machine Builders, and Manufacturers Partner With Maple Systems

Schedule a call with one of our Technical Sales Representatives. We would love the opportunity to talk with you about how we can help.

“Value, Great Support, Ease of Operation, Value Added – great website, training, stock on hand, and Innovation… makes Maple Systems one of E-PAK Machinery Inc. best partners.”

Tony Williams, Purchasing Manager E-PAK Machinery Inc.

Some of the Food & Beverage companies that trust Maple Systems

Food & Beverage Product Solutions

Food & beverage companies require control solutions that are reliable, flexible, and easy to program and update. With high brightness displays, rugged enclosures, and industry certifications, our products are designed to give you confidence in even the most demanding environments. From HMIs and Web HMIs to Industrial Panel PCs, Box PCs, HMI+PLC Combo Units, and Programmable Logic Controllers, our solutions combine safety, reliability, and performance.

Human Machine Interface (HMIs)

Choose a high resolution, sunlight readable, or a Class I, Div 2 rated touchscreen HMIs with displays ranging from 7” to 15”. Our industry-leading HMIs features include Capacitive Touchscreens, Wi-Fi, Dual Ethernet, Remote Access, IIoT protocols such as MQTT, Ignition, SparkPlug B , and more. Integrate your Allen-Bradley CompactLogix or ControlLogix, Siemens SIMATIC S7, or one of the other 400+ PLCs and controllers our free configuration software, EBPro supports.

HTML Web HMI

High Brightness Web HMIs provide a streamlined alternative to the traditional operator interface. Choose from 4.3″ 7″ and 10.1″ capacitive with 1000 nits. As client-only devices, Web HMIs are designed to connect and interact with web-based applications running on a server. No program installations and reduced wiring requirements mean that Web HMIs can be easily added into an existing control system without the need for extensive programming or configuration.

Industrial Panel PCs and Industrial Box PCs

A washdown panel PC for food processing that is cleanroom compatible or Box PC paired with our SCADA software, Aveva Edge, can create applications that are 21 CFR Part 11 compliant. Track change over and other data in a SQL database for future inspection. Because they are compatible with powerful SCADA software such as Allen-Bradley’s FactoryTalk® View, Ignition™, AVEVA™ Edge and Wonderware® or programming languages including Visual Basic, Python and C++, they provide you with a wide range of options.

HMI+PLC Combo Units

Utilized worldwide to employ diverse applications, our HMI+PLCs lower costs and save space. Specifically, they feature a variety of options designed to meet diverse industrial needs, including serial and Ethernet communication, support for Class I Division 2 installations, and numerous I/O configurations. Programmed using our Free HMI+PLC software MAPware-7000, you get access to graphs, alarms, trending, data logging, web server functionality and more, providing an affordable combination of display and control in a single package.

Programmable Logic Controllers (PLCs)

Maple Systems’ PLCs offer position control, PWM, PID with auto-tuning, High-Speed Counter (HSC), and more features to aid you in your control’s solution.

Get you control system up and running in no time with our easy-to-implement PLCs. Reliable replacements or additions to small-medium scale control systems at an affordable price.

Network Switches

Our network switches provide a high level of immunity against EMI and EMS found in industrial environments; and include features such as ESD Protection, Surge Protection, and Short Circuit Protection to ensure continuous operation in unstable power conditions. Additional capabilities like dual redundant power inputs, auto-negotiation, rate limitation, reverse polarity protection, flow and storm control, VLAN data forwarding, and QoS further optimize network performance and enhance security.

Online Technical Resources

We’ve compiled our most common technical support topics in one place to help you find the answers you need. From hardware to software, and everything in between, we’ve got you covered.

- Free Software Downloads & Upgrades – Download full versions of our HMI (EBPro) or HMI+PLC (MAPware-7000) configuration software for FREE; access demo versions of our SCADA software, Aveva Edge; and find legacy software versions anytime.

- Manuals & Guides – Our Manuals and Guides help you learn more about our products. We have Operation Manuals, Programming Manuals, and Quick Start Guides on a variety of products and functionality.

- Controller Information Sheets – Maple Systems offers support of more than 400 controller protocols for our HMI series. Controller Information sheets provide instructions and settings for each protocol, allowing your Maple Systems product to communicate with a specific Controller, including Allen-Bradley, Siemens, Omron, Idec, and many more.

- Video Center – We’ve compiled all of our most useful How-To’s, Troubleshooting, Webinar videos into convenient playlists. Choose the playlist you’d like to view below, and watch from start to finish in our video player.

- Tutorials – Browse our list of tutorials for the task you’re looking for, (or use the search function). Quickly grasp the user-friendly features of our different software programs. Follow step-by-step tutorials to guide you through the process seamlessly.

- Sample Projects – We have created sample applications/projects and sample kits that demonstrate software features, give programming information for specific controllers, or demonstrate product capabilities.

- Controller/Communication Cables – We offer hundreds of custom communication cable drawings for the industry’s most popular PLC manufacturers. Whether you want to build your own cable or have us build it for you, we can provide you with exactly what you need.

- Technical Notes – Find documentation for PLC connectivity, email, setting IP addresses, alarms, recipes, macros, and more.

- Solutions – Our Case Studies and Application Stories show real-life applications and how Maple Systems can help improve your company’s bottom-line. Read articles on key software features, connecting current or legacy systems to the IIoT, and improving how you collect, analyze, and manage data.

Free U.S. Based Support

If you weren’t able to find answers in our Support Center, you can ask a product or service-related question by:

- Opening a case with our Technical Support by using our online Case Logger. From this page, enter as much information as possible and a member of our Technical Support team will contact you within 2 business days.

- Reaching out to our Sales team. Email us at [email protected] or call 425-745-3229. We are here M-F 6:00am – 4:30pm Pacific Time to answer your questions.

Large In-Stock Inventory

We carry a large inventory, and most models can ship the next business day. Because we are located on the West Coast, we can handle late orders and get you what you need, fast.

Maple Systems offers our customers the ability to place Blanket Purchase Orders to better manage your inventory and cash flow. Additionally, this strategy helps our production team guarantee we can meet your delivery needs.

Flexible Pricing Structure

Our tiered pricing structure gives customers the most flexibility in purchasing. We will work with you to determine available discounts and maintain pricing from order-to-order regardless of order size.

Call 425-745-3229 or email our Sales team at [email protected] for a quote today

Built-In Industry Drivers

One of the advantages of our free programming software, EBPro, is its extensive library of built-in drivers, including support for popular industry PLCs and RTU controllers:

- Allen-Bradley CompactLogix and ControlLogix

- Siemens S7 family

- Omron

- Maple Systems

Real Application:

Frito Lay partners with Douglas Machines to provide high quality automated packaging solutions for the salty chip division. Douglas specializes in the design and manufacture of case and tray packers, shrink wrap systems, cartoners, sleevers, variety pack systems and palletizers. We are proud to partner with Douglas to provide our High-Performance 9.7″ HMI to bagging machines for Frito Lay/Pepsi Co.

Try Before You Buy

We offer multiple ways for you to test and learn our FREE software before you buy any hardware. After downloading the software, walk through the tutorials, watch our videos, use the sample projects, or even attend a webinar.

- Try our HMI Configuration (EBPro) Software – Download, Connect, Run Simulation. Check out our article as we walk you through downloading the software, creating a project, and run the project with offline and/or online simulation.

- Try HMI+PLC Combo (MAPware) Software – Quickly grasp the user-friendly features of MAPware-7000, by following step-by-step tutorials to guide you through the process seamlessly.

- Try SCADA (Aveva Edge) Software – The AVEVA™ Edge demo will run in “Evaluation Mode” for 40 hours before requiring you to purchase a license. It demonstrates the full capabilities of the software.

Now that you’ve explored the software, we can provide you a demo unit for testing potential applications, or to use in an evaluation. Demo units are available for up to 30 days. Contact our sales team for more information on a demo unit.

Food & Beverage Case Studies

At Maple Systems, we’ve partnered with customers across industries to deliver automation solutions that solve real-world challenges. From increasing throughput, reducing labor costs, to increasing quality, our technology is trusted in food & beverage companies around the world.

Increase Throughput

Reduce labor costs and increased quality.

Automated Dairy started its own research and development division where they manufactured a proprietary automated dairy system called TURBOWASH. When looking into designing the user interface, Automated Dairy selected a Maple Systems 9.7″ HMI to work with the PLC. The integrated solution allows the user total access to all the dairy’s daily milking functions, ensuring consistency and proactive control in milking.

Increase Quality

Enhanced safety and compliance.

Every Harvest Right Freeze Dryer has been designed, engineered and hand-assembled with care. They spent four years designing and engineering this product to roll out to the world and use a Maple Systems 4.3″ HMI as the display of choice. This product is built to last and can preserve the foods you and your family will love for years to come.

High-Output Capabilities

Remote Access and Flexibility.

Cetec Cereal Technologies serves the cereal milling and food processing industries. When Cetec decided to pursue the development of its own range of specialized process equipment such as the highly regarded HTX Grain Heater and the revolutionary Hydromax Flour Hydrator they decided on Maple HMIs as their go-to operator display. Because our HMIs support over 400 PLCs and controllers, including Allen-Bradley and Siemens, our HMI was the ideal user interface.

Enhanced Traceability

The ability to track products from end-to-end is critical in the food and beverage industry. Automation significantly improves traceability which means a product can be readily tracked from its source, through processing and distribution, until it reaches the shelf for consumers. If a problem is detected with a batch of products, the shipment can be located and retrieved, avoiding potential issues. Improved traceability provides valuable data that allows manufacturers to ensure regulatory compliance and cut down on the cost of compliance. This data also allows for trouble-shooting and identification of issues along the supply chain – allowing for continuous improvement and enhancing overall quality, safety, and profitability.

Increase Efficiency

Automated processes can work 24/7 with occasional outages for maintenance, which is clearly faster than human operators can perform. For this reason, increased efficiency and higher through-put rates are two of the biggest benefits of automation in the food and beverage industry. In addition to elevated efficiency, automation also allows companies to collect valuable data from the production line that can be used to improve maintenance. Predictive maintenance is used to identify potential issues and alert when maintenance is needed – further reducing costs as well as production downtimes.

Customer Service / Warranty

At Maple Systems, providing exceptional customer service is our top priority. As a valued customer, you’ll work with a dedicated Account Manager who knows your business. They are ready to assist with any request: from starting a technical support case and checking order status to locating a missing invoice.

Our online customer portal makes it easy to manage your account anytime. You can view and print sales orders, track shipments, update shipping addresses, and access invoices or our secure payment portal 24/7. In addition, customers with specific permission levels can buy on terms and see established discounts directly on the website. For more details, contact your Account Manager.

Support & Service Resources

- Returns / Repairs

- Warranty Statement

- Start a Support Case

- Contact Sales

- How to Place an Order

- Online Account Benefits

- FAQs

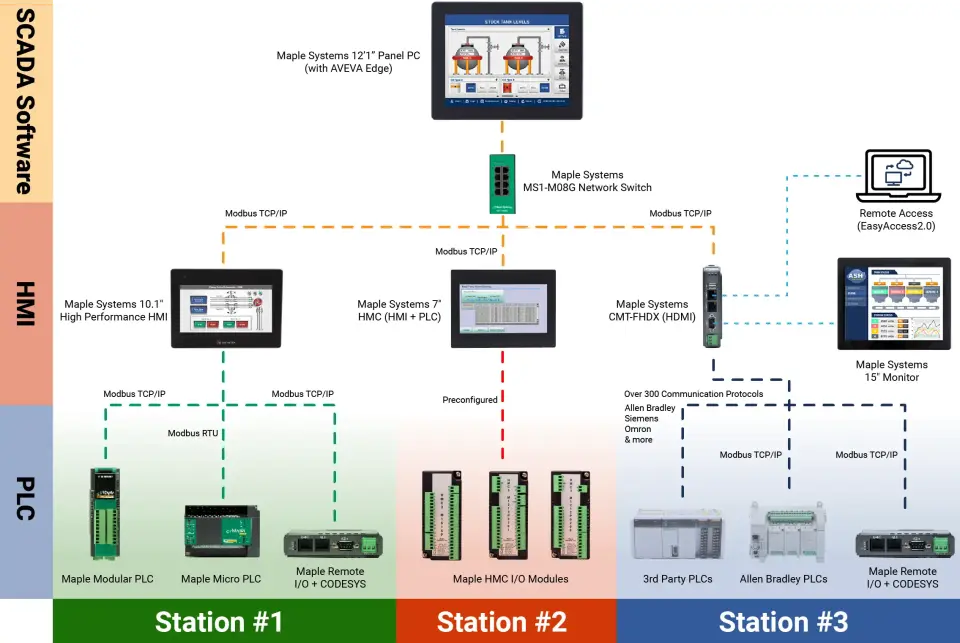

SCADA

Maple Systems offers all the components you need to build your own supervisory data acquisition and control system. This ranges from simple stand-alone machines to sophisticated multi-device networked production lines. In addition, we support enterprise-level operations and IIoT functionalities that leverage cloud connectivity.

- Log data from your devices to aid in reporting, improve efficiency, and reduce downtime.

- Use it to plan routine maintenance with ease.

- Add IIoT functionality such as MQTT, OPC UA, Ignition, SQL database integration, and more.

Our products can help you standardize communications between devices, gluing different systems together for one source to your SCADA. No need to redesign your entire application.

Keep the components that are already working for you, just add Maple Systems components to grow your abilities to supervise, control, and acquire data.

To learn more about how our products work together to create scalable SCADA solutions, visit our SCADA solutions page.