High Brightness HMI

Our 7” high brightness HMI gives you all the functionality available in our High-Performance Series plus a 1200 nit sunlight readable display.

For systems where size does matter, we created high bright combo units that provide you with the processing power of our Advanced and High-Performance headless HMIs, and the option to choose from our 4.3” to 21.5” sunlight readable displays.

Ranging in 4.3”, 7”, and 10.1”, our high bright, Web HMIs come standard with a built-in Chromium Browser, HTML5 Powered, IP66, Class I, Division 2 rating, without the need for conversion or re-engineering.

Results

-

7.0″ C1D2 Rated, Rugged High Brightness, Extended-Temperature HMI

cMT3072XHTL- 1024 x 600 Resolution, 2 Ethernet Ports, 1 USB Port, 2 Serial Ports, Aluminum Enclosure

- High Brightness, 1200 nits

- Advanced features include PDF Reader, Web Streaming, Web View, and Web Browser

- Remote Access, supports MQTT JSON/AWS IoT, SQL Database and OPCUA servers

- Pair with our remote IO modules for soft PLC functionality

- UL, C1D2, CANbus, CE, RoHS, IP66, NEMA4

$919.00Quantity Discounts Available -

4.3″ High Brightness Web HMI Display, HTML5 Powered, UL C1D2 Rated

WP4043AP- Capacitive Touchscreen Technology

- Built-in Chromium Browser Version 75

- Pair with our Industrial Embedded Box PCs or our Headless HMIs

- UL Class 1 Division 2 Hazardous Location Rated

- IP66 Rated for Washdown Environments

- 480 x 272 Pixel Resolution, High-Brightness 1000 nits

$445.00Quantity Discounts Available -

4.3″ High Brightness Web HMI and cMT-SVRX-820 Package

- Headless HMI – cMT-SVRX-820

- 2 Ethernet, 1 USB, 1 Serial Port

- 1GB RAM, 4GB Flash

- cMT-SVRX-820 Data Sheet

- 4.3″ HTML5 Web HMI Touchscreen

- High Brightness 1000 nits

- Free Programing Software

- WP4043AP Data Sheet

-

-

4.3″ High Brightness Web HMI and cMT-SVRX-822 Package

- Headless HMI – cMT-SVRX-822

- 2 Ethernet, 1 USB, 1 Serial Port

- EasyAccess 2.0 Included

- 1GB RAM, 4GB Flash

- cMT-SVRX-822 Data Sheet

- 4.3″ HTML5 Web HMI Touchscreen

- High Brightness 1000 nits

- Free Programing Software

- WP4043AP Data Sheet

-

7.0″ High Brightness Web HMI Display, HTML5 Powered, UL C1D2 Rated

WP4070AP- Capacitive Touchscreen Technology

- Built-in Chromium Browser Version 75

- Pair with our Industrial Embedded Box PCs or our Headless HMIs

- UL Class 1 Division 2 Hazardous Location Rated

- IP66 Rated for Washdown Environments

- 1024 x 600 Pixel Resolution, 1000 nits

$725.00Quantity Discounts Available -

7″ High Brightness Web HMI and cMT-SVRX-820 Package

- Headless HMI – cMT-SVRX-820

- 2 Ethernet, 1 USB, 1 Serial Port

- 1GB RAM, 4GB Flash

- cMT-SVRX-820 Data Sheet

- 7″ HTML5 Web HMI Touchscreen

- High Brightness 1000 nits

- Free Programing Software

- WP4070AP Data Sheet

-

7″ High Brightness Web HMI and cMT-SVRX-822 Package

- Headless HMI – cMT-SVRX-822

- 2 Ethernet, 1 USB, 1 Serial Port

- EasyAccess 2.0 Included

- 1GB RAM, 4GB Flash

- cMT-SVRX-822 Data Sheet

- 7″ HTML5 Web HMI Touchscreen

- High Brightness 1000 nits

- Free Programing Software

- WP4070AP Data Sheet

-

10.1″ High Brightness Web HMI Display, HTML5 Powered, UL C1D2 Rated

WP4101AP- Capacitive Touchscreen Technology

- Built-in Chromium Browser Version 75

- Pair with our Industrial Embedded Box PCs or our Headless HMIs

- UL Class 1 Division 2 Hazardous Location Rated

- IP66 Rated for Washdown Environments

- 1024 x 600 Pixel Resolution, High-Brightness 1000 nits

$940.00Quantity Discounts Available -

10.1″ High Brightness Web HMI and cMT-SVRX-820 Package

- Headless HMI – cMT-SVRX-820

- 2 Ethernet, 1 USB, 1 Serial Port

- 1GB RAM, 4GB Flash

- cMT-SVRX-820 Data Sheet

- 10.1″ HTML5 Web HMI

- High Brightness 1000 nits, Capacitive Touchscreen

- Free Programing Software

- WP4101AP Data Sheet

-

10.1″ High Brightness Web HMI and cMT-SVRX-822 Package

- Headless HMI – cMT-SVRX-822

- 2 Ethernet, 1 USB, 1 Serial Port

- EasyAccess 2.0 Included

- 1GB RAM, 4GB Flash

- cMT-SVRX-822 Data Sheet

- 10.1″ HTML5 Web HMI

- High Brightness 1000 nits, Capacitive Touchscreen

- Free Programing Software

- WP4101AP Data Sheet

-

10.4″ High Brightness Industrial Monitor and cMT-FHDX-820 Package

- Headless HMI – cMT-FHDX-820

- Full HD 1080P High Resolution Video Output

- cMT-FHDX-820 Data Sheet

- 10.4″ Touchscreen Monitor

- High Brightness 1000 nits

- Free Programing Software

- MON1010APHv2 Data Sheet

-

12.1″ High Brightness Industrial Monitor and cMT-FHDX-820 Package

- Headless HMI – cMT-FHDX-820

- HD High Resolution Video Output

- cMT-FHDX-820 Data Sheet

- 12.1″ Touchscreen Monitor

- High Brightness 1000 nits

- Free Programing Software

- MON1012APHv2 Data Sheet

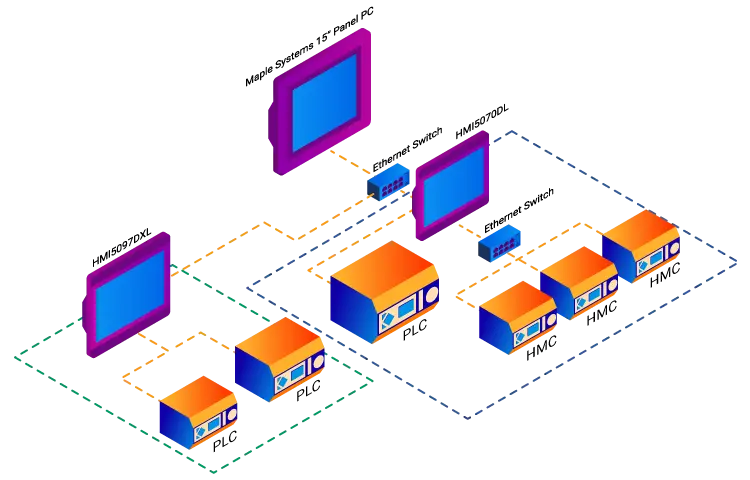

User Friendly HMI Configuration Software

Free, powerful HMI configuration software for our HMIs provides the flexibility to create and deploy custom control applications suited to your unique industrial process. With support for over +400 PLC & controller communication protocols, EBPro enables our HMIs to seamlessly integrate with your new or existing system.

Programmable Logic Controller (PLC) Connectivity

With over +400 PLC & Controller communication protocols, these HMIs will easily integrate with your preferred PLC brands, including:

- Maple Systems

- Allen-Bradley

- Siemens

- Omron

- Emerson

- GE

- Panasonic

- Mitsubishi

- …and many more

Read more about connecting a Maple Systems PLC to one of our HMIs

What are Nits?

Monitor Luminance is measured in candelas per square meter (cd/m²), sometimes referred to as “nits.” Sunlight readable displays provide higher light output, sometime double the nits of standard displays, and often feature special filters to reduce glare.

400-700 nits would be required for use in normal daylight conditions, and at least 1,000 nits is required for viewing in direct, bright sunlight. Our High Brightness/Sunlight Readable Industrial Panel PCs and Monitors come standard with 1,000 nits.

Rugged Construction

Our High Brightness Industrial Panel PCs and Monitors are IP65 rated and have a steel black chassis, making them extremely durable.

IP65 Rated

Our High-Brightness units are designed and tested for harsher environments making them ideal to withstand prolonged shock & vibration, a wide temperature range, and protection from water and dust.

What is IP65?

IP65 – IP rated as “dust tight” and protected against water projected by a nozzle (6.3 mm) against enclosure from any direction. IP65 rated panel PCs can be sprayed clean and prevent ingredients from making their way into the system and causing damage to components.

- Complete protection from dust, oil, and other non-corrosive material

- Complete protection from contact with enclosed equipment

- Protection from water, up to water projected by a nozzle against enclosure from any direction

- Silk-screening, anodizing, or engraving services available

- Custom with cutouts, insulation, hinges, latches, or locks

Industries Around the World

Improved traceability provides valuable data

Companies around the globe rely on Maple Systems products to help ensure uninterrupted production of critical resources. Whether you’re designing for a new application or updating an existing one, Maple Systems offers industrial automation and networking solutions that provide the connectivity, monitoring and control required to get the job done.

Read our Case Studies

Read how one of our customers created a high-brightness HMI by pairing our HDMI-enabled headless HMI with one of our industrial monitors

By adding the HDMI-enabled headless HMI and a high-brightness industrial monitor to the application, our customer was able to interface to the existing drives and PLC to collect production data using the HMI software communication drivers. The headless HMI also monitors for alarm conditions, creates a log file for reporting, and save the data to an attached USB stick The large, clear, bright 21.5” monitor is VESA mounted above the equipment where it can be seen from a distance around the machine. And the bright 1000nit display overcomes difficulties from the factory lighting glare and surrounding equipment, enabling workers to clearly see machine status’ and quickly resolve any alarm conditions that occur. Read more about this customer’s application.

Supervisory Control and Data Acquisition (SCADA)

Early on, these types of systems were built using proprietary hardware and software, operating in isolation without connections to other networks. Operators had to reside in a centralized control room or command center because human-machine interfaces. (HMIs) did not support remote access. Any information provided to personnel other than operators was delivered via reports, which often had a significant time lag. Once devices were connected to much larger networks, they became more complex and gained broad capabilities

To learn more about how our Class I, Division 2 products work together to create scalable SCADA solutions, visit our SCADA solutions page.

Customize Your HMI, HMI+PLC, or PC

Highlight your brand and differentiate your machine with a custom label

Company branding is a significant aspect of business marketing. By using custom labels on your products, you can create an identity to gain recognition from customers and potential buyers. It helps consumers recognize that the product was made by your company. Having this type of brand recognition can help your business stand out from competitors. Our Custom Labels:

- Fit Your Product Perfectly

- Offer Professional-Looking Packaging

- Strengthens Your Marketing Efforts

- Provides an Identity to Your Business