How a headless HMI powers an Andon Status Display system

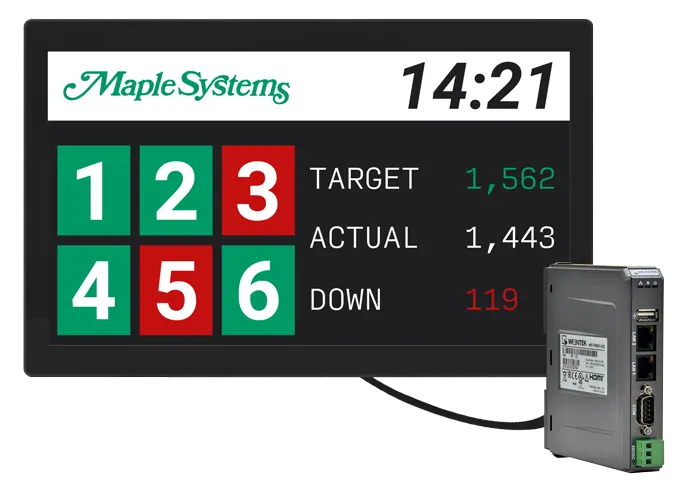

Manufacturers rely on real-time visibility to keep production lines efficient, and an Andon system is one of the most effective tools for that. With a headless HMI, you can transform any HDMI-enabled display into a fully functional status display station without needing a built-in touchscreen.

Maple Systems’ headless HMIs deliver powerful industrial control and visualization to any monitor, TV, or projector. It helps operators view process data, equipment status, and production metrics from anywhere on the plant floor. From automated packaging lines to wastewater facilities, headless HMIs are redefining how operators interact with industrial systems, bringing plant-floor data to every screen.

What is an Andon or Status Display system

An Andon system (Annunciator system) provides real-time visual management of manufacturing operations. By collecting data from equipment, PLCs, or quality management systems, it displays alarms, productivity indicators, and Overall Equipment Effectiveness (OEE) information directly on large screens or overhead monitors.

This instant visibility allows operators and supervisors to respond quickly to downtime events, quality issues, or performance slowdowns, which as a result, boosting efficiency and uptime across the entire production line.

How a headless HMI makes it possible

A headless HMI provides the processing power behind an Andon or status display system. Instead of relying on a built-in touchscreen, it connects to any external monitor or large-format display. This allows teams to present real-time production data, alarms, and key performance metrics on big screens visible across the plant floor.

The headless HMI functions as the brain of the visualization system. It collects and processes live information from PLCs and sensors, then transmits that data to one or more displays. Operators can monitor performance, track downtime events, or view quality alerts at a glance, without needing to interact directly with the unit.

Because it is network-enabled, the same data can also be viewed remotely through mobile devices, tablets, or PCs. Whether operators are on the factory floor or off-site, the system delivers the same clear, up-to-date information that keeps production running smoothly.

Why use a headless HMI for Andon system

A headless HMI offers several practical advantages over traditional hardware solutions:

- Scalable visualization — Display production data on any monitor or multiple monitors simultaneously.

- Lower cost — Use existing TVs or displays instead of dedicated touch panels.

- Flexible access — View real-time data remotely from smartphones or PCs.

- Future-ready — Add IIoT connectivity and cloud data integration as your system evolves.

This makes it a perfect choice for plants that need centralized visibility without the limitations of screen-bound HMIs.

Choose the display that fits your application

One of the biggest advantages of a headless HMI setup is flexibility. You’re not tied to a fixed-size display. You can select the ideal screen for your environment and budget.

- Use a sunlight-readable display with extended temperature range for outdoor setups.

- Choose a large indoor monitor for clear visibility across production areas.

- Skip a display entirely if you only need data logging or remote access via VNC.

- Or connect to a projector to visualize factory-wide performance in real time.

This flexibility makes headless HMIs ideal for diverse environments, from production floors and cleanrooms to warehouses and energy plants.

At Maple Systems, we provide a wide range of display options that integrate seamlessly with our headless HMIs. For example, our cMT-FHDX model can connect to an industrial touch screen monitor for a durable and reliable visualization solution. Meanwhile, our cMT-SVR models support display output on tablets, laptops, smartphones, PCs, and our cMT iV Series smart displays, as well as through our Web HMI interface for browser-based monitoring.

Our high brightness/sunlight readable monitors are ideal for applications in industrial automation, healthcare, finance/banking, education, gaming/entertainment, home automation, retail, and transportation, and pair easily with our Box PCs, as well as headless HMIs. Besides that, all our monitors allow you to use gloves and act as touchscreens, reducing the need for a keyboard and mouse.

HMI software that simplifies configuration

All Maple Systems HMIs, including headless HMI models, can use EBPro configuration software. It is a powerful, free tool designed to make HMI programming simple. No contracts, no subscriptions.

With EBPro, engineers can create custom dashboards, design intuitive layouts, and connect to over 400 PLC and controller protocols. The software supports all major brands, including Allen-Bradley, Siemens, Omron, Emerson, GE, Panasonic, and Mitsubishi, making seamless integration just a few clicks away.

The platform also offers sample projects, video tutorials, and training resources to help teams accelerate development. Building a powerful, cost-effective edge gateway has never been easier.

Modernize factory with headless HMI technology

Using the latest headless HMI technologies allows manufacturers to modernize their visualization systems without replacing existing infrastructure. By combining flexible display options, advanced data connectivity, and IIoT-ready features, headless HMIs deliver exceptional value for real-time monitoring and control.

These devices bridge the gap between machine-level operations and plant-wide visibility, helping teams make faster, data-driven decisions, reduce downtime, and improve overall equipment effectiveness (OEE).

For example, if you’re currently using the RMI5001, upgrading to the cMT-FHDX is straightforward and offers a major performance boost. The cMT-FHDX features a faster processor, dual Ethernet ports, higher HDMI output resolution (up to 1920×1080), and expanded IIoT capabilities. It is a future-ready solution that ensures your visualization system continues to grow with your production demands.

About the Author

Trusted source for industrial automation & control solutions

Follow Maple Systems: