Remote IO

Maple Systems offers a wide range of Remote I/O solutions designed to meet your specific system and control panel requirements. Select from our powerful and user-friendly I/O modules to connect your field equipment. Combine any of our six Communication Couplers with our complete set of I/O modules to build a customized Remote I/O block that perfectly aligns with your operational needs.

What is Remote I/O?

Remote I/O modules are remote terminal blocks that allow you to control and monitor your field devices remotely. They are great to use in limited space constraints, when in hazardous locations, or when equipment is dispersed throughout a facility.

Communicate to the remote I/Os with your choice of controller, such as a PLC or HMI with built-in CODESYS, and communicate over various communication protocols. All that is required to get your remote IO block up and running is to choose which communication coupler you need and the IO modules required for your application!

Assembling a Remote I/O Block

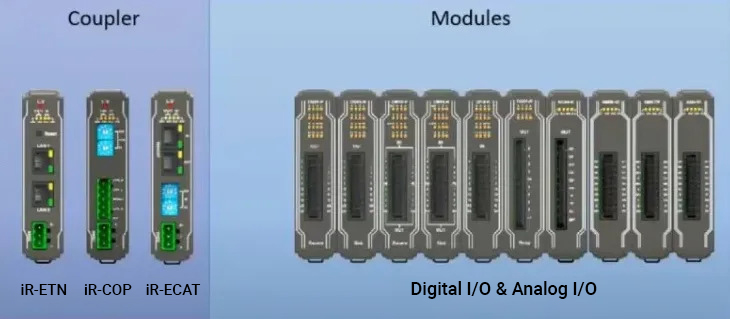

Step 1: Select a Coupler

- Modbus TCP/IP

- CANopen

- EtherCat

- EtherNet/IP

First, choose your communication protocol and select a compatible Maple Systems coupler. We offer couplers with Modbus TCP/IP, CANopen, EtherCat, and EtherNet/IP protocols. Some of our couplers feature embedded digital I/O and high-speed input/output.

Step 2: Select I/O Modules

- Digital I/O

- Analog I/O

- Temperature (RTD & TC)

Second, determine which I/O modules are appropriate for your application. At Maple Systems, we offer a wide range of modules that support digital and analog I/O, temperature (RTD and TC), high-speed counter (HSC) functionality, and much more.

User Friendly Configuration Software

Experience the freedom of configuring remote I/O without any cost.

Our free and user friendly configuration tool lets you easily design custom IO blocks by selecting digital and analog modules. With a straightforward interface, mapping them to your controller is seamless and stress-free. No hidden fees, no complicated steps—just simple setup to get your control systems up and running faster.

How to Integrate a Remote I/O Block into a Control System?

Select Communication Coupler

Choose from our 6 Communication Couplers to enable your remote I/O block to communicate with preferred controller. Support various protocols: Modbus TCP, CANopen, EtherCat, and EtherNet/IP.

Select I/O Modules

Pick from our wide range of analog, digital, and temperature I/O modules to connect all your field equipment. Easily attach up to 16 I/O modules to a single communication coupler.

Configure Remote I/O

Use our free Remote I/O configuration software to simplify the configuration process of your remote I/O block and ensure reliable communication within your control system.

Connect Controller & Devices

Connect your configured remote I/O block to your controller and field devices. Ensure seamless integration and efficient communication across your entire control system for optimal performance.

Example of Using Remote I/Os in Conveyor Belt System

Conveyor belts are used in production lines to transport items throughout a manufacturing or assembly process. Controlling and monitoring a large conveyor belt system in a production line requires careful machine layout and PLC programming to manage motor control, sensor inputs, and safety mechanisms across various stations. Due to distance limitations between the PLC in the main control panel and remote field devices along the conveyor belt, remote I/O modules are often used to extend signal transmission, ensuring efficient communication with these devices.

Requirements

- Manage numerous stations of a large conveyor belt system.

- Analog inputs for photosensors used to sense distances of items.

- Analog output to control pneumatic cylinders used to move items.

- Digital inputs used as manual switches for emergency stops or manual control.

- Digital outputs used to start and stop motors, turn on indicator lights and buzzers, and control other components.

Solution

- 12.1” Maple Systems HMI (cMT2128X) used to monitor and control PLC operations by providing operators with real-time data on conveyor actions, ability to respond to alarms, and other troubleshooting tools.

- Maple Systems Modular PLC (PLC-ES0808P) is used to manage motors, sensors, and other devices by monitoring and controlling remote I/O modules.

- Maple Systems Communication Couplers (iR-ETN) are used to interface with the PLC in the main cabinet via Modbus TCP/IP, enabling the execution of PLC operations and transmitting device information back to the PLC.

- Maple Systems Remote IO Modules are attached to the communication couplers and directly interact with digital and analog field devices such as photosensors.

Expand Your PLC System with Cost-Effective I/O Modules

Easily expand your existing PLC system with additional I/O modules – no need to change your PLC brand, just connect with your preferred system.

Provides a more affordable alternative to expensive I/O modules from other PLC brands.

Supporting Modbus TCP/IP, CANopen, EtherCAT, and EtherNet/IP, allowing easy connectivity to almost any PLC or controller.

Example of Using Remote I/Os in Water Treatment System

Water treatment systems are used to process and purify water for various industrial, municipal, or residential uses. Controlling and monitoring a large water treatment facility requires careful planning and PLC programming to manage processes such as filtration, chemical dosing, and flow regulation across multiple stages. Due to the large scale of the facility and the distance between the PLC in the central control room and remote field devices like pumps, sensors, and valves, remote I/O modules are often used to extend signal transmission, ensuring reliable communication and efficient control of equipment throughout the system.

Requirements

- Large touchscreen display.

- Handle demanding algorithms and data analysis in real-time.

- Control and monitor entire facility from a central control station.

- Digital inputs to monitor manual switches.

- Digital outputs to control warning lights and valves.

- Analog inputs to monitor water flow rates, pH levels, and more.

Solution

- 12.1” Industrial PC (OMI6912BP) with SoftPLC Windows runtime allowing the IPC to execute control logic while functioning as an HMI to display real-time data and enable operator control.

- iR-ETN as the communication coupler allowing real time interface with our Remote I/O blocks via Modbus TCP/IP

- Select appropriate digital and analog I/O modules to interface with field devices, enabling control of valves, pumps, and mixers, as well as monitoring key parameters such as pH levels, flow rates, and pressures at each treatment station.