Building Automation

HVAC | Lighting | Security | Safety | Energy Management

Modern building automation systems deliver multiple strategic advantages through integrated technology platforms. Primary objectives include enhancing occupant comfort, optimizing building system performance, minimizing energy consumption, and reducing operational and maintenance expenses. Additional benefits encompass strengthened security protocols, comprehensive historical performance documentation, seamless remote access and control capabilities, and extended equipment lifecycle management across all connected utilities.

Contemporary building management system technology provides sophisticated answers to complex automation and industrial process control challenges. These innovations leverage HVAC control panel technology, industrial computer infrastructure, and intuitive touchscreen interfaces to deliver real-time monitoring and adjustment capabilities. Energy monitoring systems track consumption patterns and identify optimization opportunities, while access control panel integration ensures comprehensive facility security. Advanced PC interface connectivity enables centralized oversight and computer building intelligence that transforms traditional facilities into responsive, data-driven environments capable of adapting to changing operational demands and maximizing efficiency across all building systems.

Table of Contents

Building Automation Companies Partner With Maple Systems

Schedule a call with one of our Technical Sales Representatives. We would love the opportunity to talk with you about how we can help.

Some of the Building Automation companies that trust Maple Systems

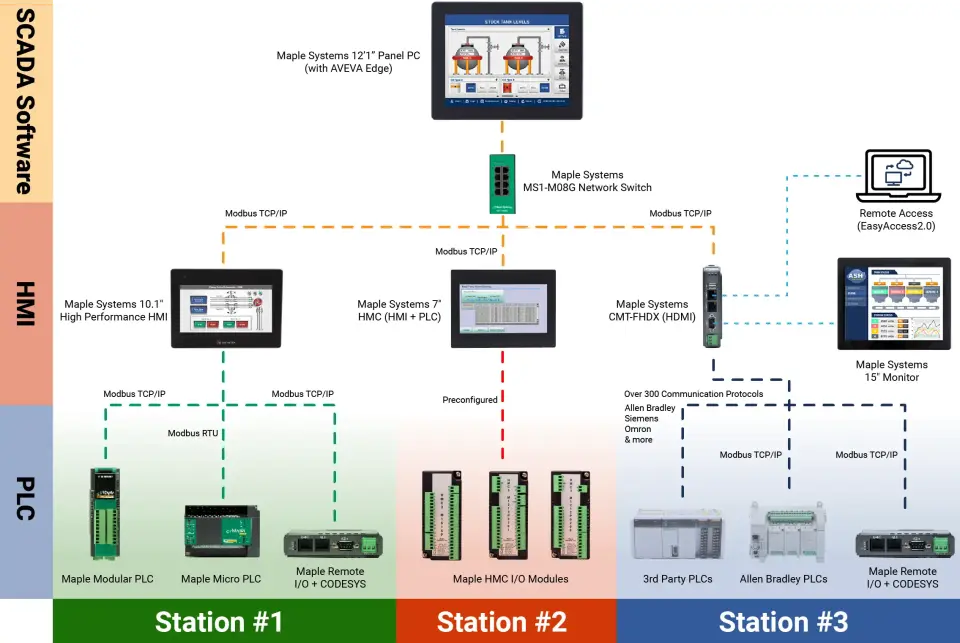

Integrated Products for Building Solutions

At Maple Systems, we have a wide selection of industrial products designed to work together, giving you confidence in any environment. From HMIs and PLCs to Industrial Panel PCs, Box PCs, Network Switches, and HMI+PLC Combo Units, our solutions combine safety, reliability, and performance.

Human Machine Interface (HMIs)

From control room to control panel, our industry-leading HMIs features include Capacitive Touchscreens, Wi-Fi, Dual Ethernet, Remote Access, IIoT protocols such as MQTT, Ignition, SparkPlug B, and more. Integrate with a Maple Systems HMI using BACnet. Additionally, our HMIs support over 400 PLC and controllers in our free configuration software, EBPro.

Programmable Logic Controllers (PLCs)

Maple Systems’ PLCs offer position control, PWM, PID with auto-tuning, High-Speed Counter (HSC), and more features to aid you in your control’s solution. Our PLCs adapt to a wide variety of applications, which makes them ideal for complex control systems, ensuring your automation setup grows alongside your business. Get your control system up and running in no time with our easy-to-implement PLCs. Reliable replacements or additions to small-medium scale control systems at an affordable price.

Industrial Panel PCs and Industrial Box PCs

Our Industrial PCs can serve as an intelligent building automation terminal and come with a Windows® Operating System installed that can operate any Windows® Software, powerful SCADA software such as Allen-Bradley’s FactoryTalk® View, Ignition™, AVEVA™ Edge and Wonderware®, or configure them using programming languages such as Visual Basic, Python and C++, providing you with flexible options.

Industrial Network Switches

Our network switches provide a high level of immunity against EMI and EMS found in industrial environments; and include features such as ESD Protection, Surge Protection, and Short Circuit Protection to ensure continuous operation in unstable power conditions. Additional capabilities like dual redundant power inputs, auto-negotiation, rate limitation, reverse polarity protection, flow and storm control, VLAN data forwarding, and QoS further optimize network performance and enhance security.

HMI+PLC Combo Units

Utilized worldwide to employ diverse applications, our HMI+PLCs lower costs, save space, and feature options including: Serial and Ethernet communication and numerous I/O configurations. Programmed using our Free HMI+PLC software MAPware-7000, you get access to graphs, alarms, trending, data logging, web server functionality and more, providing an affordable combination of display and control in a single package.

Remote Monitoring for Building Automation

Remote access or monitoring allows you to reach an HMI or connected device anytime, from anywhere. With our EBPro HMI configuration software and supported hardware solutions, you can connect to an HMI or Gateway device from a tablet, smartphone, or PC.

We have several remote access solutions. Keep in mind that each remote access solution will work slightly differently and have their own set of features. Depending on your specific situation, there may be several remote access solution that will work, only you can decide what is best for your specific situation.

EasyAccess2.0

EasyAccess2.0 is a secure access utility that enables remote access to Maple Systems’ HMI and cMT Series devices. View and control any remote HMI with EasyAccess 2.0 from a PC or mobile device, allowing you to resolve issues immediately as they arise from anywhere in the world.

- Control your remote HMIs like you’re standing in front of them.

- Upload/Download projects to modify and test your HMI Programs.

- Interact with connected PLCs using the PLC Passthrough mode.

cMT Viewer

cMT Viewer is remote connection software built into our EBPro HMI configuration platform that allows you to monitor and manage your devices from anywhere. It works with select Maple Systems IIoT-ready HMIs and can run on PCs, Panel PCs, iPads, and Android tablets.

Key benefits include:

- Free download for quick setup

- Monitor up to 50 HMIs at once

- Faster connections with less bandwidth (only application data is exchanged)

To learn more, read our article What is cMT Viewer?

WebView

WebView enables you to point your browser to the supported HMI’s IP address on your local network and log in. Now you have access to all the functions, data, and project screens from your HMI application. You can access system settings, navigate to any window, and fully control your HMI from anywhere. No need to download or install any additional software!

VNC

VNC (Virtual Network Computing) server is built in on all our HMIs. Any third party VNC viewer client can log into a Maple HMI to see and control exactly what’s shown on the HMI screen. Configurable options on the Maple HMI include: set a password, enable monitor mode (view only – no control), allow single connection or multiple connections.

Online Technical Resources

We’ve compiled our most common technical support topics in one place to help you find the answers you need. From hardware to software, and everything in between, we’ve got you covered.

- Free Software Downloads & Upgrades – Download full versions of our HMI (EBPro) or HMI+PLC (MAPware-7000) configuration software for FREE; access demo versions of our SCADA software, Aveva Edge; and find legacy software versions anytime.

- Manuals & Guides – Our Manuals and Guides help you learn more about our products. We have Operation Manuals, Programming Manuals, and Quick Start Guides on a variety of products and functionality.

- Controller Information Sheets – We offers support of 400+ controller protocols for our HMI series. Controller Information sheets provide instructions and settings for each protocol, allowing your Maple Systems product to communicate with a specific Controller – including Allen-Bradley, Siemens, Omron, Idec, and many more.

- Video Center – We’ve compiled all of our most useful How-To’s, Troubleshooting, Webinar videos into convenient playlists. Choose the playlist you’d like to view below, and watch from start to finish in our video player.

- Tutorials – Browse our list of tutorials for the task you’re looking for, (or use the search function). Quickly grasp the user-friendly features of our different software programs. Follow step-by-step tutorials to guide you through the process seamlessly.

- Sample Projects – We have created sample applications/projects and sample kits that demonstrate software features, give programming information for specific controllers, or demonstrate product capabilities.

- Controller/Communication Cables – We offer hundreds of custom communication cable drawings for the industry’s most popular PLC manufacturers.

- Technical Notes – Find documentation for PLC connectivity, email, setting IP addresses, alarms, recipes, macros, and more.

- Solutions – Our Case Studies and Application Stories show real-life applications and how Maple Systems can help improve your company’s bottom-line. Read articles on key software features, connecting current or legacy systems to the IIoT, and improving how you collect, analyze, and manage data.

Free U.S. Based Support

If you weren’t able to find answers in our Support Center, you can ask a product or service-related question by:

- Opening a case with our Technical Support by using our online Case Logger. From this page, enter as much information as possible and a member of our Technical Support team will contact you within 2 business days.

- Reaching out to our Sales team. Email us at [email protected] or call 425-745-3229. We are here M-F 6:00am – 4:30pm Pacific Time to answer your questions.

Built-In Industry Drivers for Building Automation

Our free HMI programming software has an extensive library of built-in drivers, including support for popular industry PLCs and RTU controllers:

- Siemens SIMATIC S7 Series

- Schneider Electric

- ABB AC500 Series

- Mitsubishi Electric MELSEC Series

- Allen-Bradley ControlLogix and CompactLogix Series

Applications for Building Automation

At Maple Systems, we’ve partnered with customers across industries to deliver automation solutions that solve real-world challenges. From HVAC, lighting, other building systems, to security, energy management, and remote access systems, our technology is trusted.

Wide Product Selection

Fives Lund, a system integrator, chose one of our Industrial PC to run their SCADA software package on the Space Needle. The function of the Maple Systems Industrial PC is pretty straight-forward.

“It allows the operators to set the speed and direction of the rotating glass floor, and gives us the ability to monitor of any faults or warnings, and a view into the load-sharing by the twelve AC motors that spin that turntable,” said Ken Roach, Senior Controls Engineer, Fives Lund

Energy Management

Maple Systems has thousands of installations dedicated to energy management. Customers have noticed savings in the 20 to 50% ranges are not uncommon. Wireless and remote installations, collecting data and reporting back to a centralized facility helps customers manage many locations at once.

HVAC

Heating, Ventilating and Air Conditioning provide comfort and safe working conditions – so don’t allow unexpected failures to catch you off guard. Real-time monitoring and trending of system performance with a HVAC control panel computer, efficiency and output monitoring allows you to predict problems before they occur. Furthermore, scheduled maintenance is not easily forgotten because staff receive an email or message on their mobile phone providing notification of the exact operation to be performed. From changing a filter to lubrication, to full system tests that may be years apart, let our solutions provide the peace of mind you need.

Lighting

Commercial buildings can be mammoth-sized energy and expense wasters. And when energy is wasted, it leads to the loss of jaw-droppingly big bucks—millions nationally, according to research. A building automation system can control lighting using schedules, manual controls, occupancy sensors, and photosensors, either singly or in combination. Much of the energy savings produced by a building automation system comes from scheduling the operation of electrical loads. Our intuitive HMI configuration software and HMI products can help you reduce wasted energy and costs.

Security

This digital transformation of the building automation sector involves moving away from older proprietary systems and adopting edge-to-cloud computing architectures. Our industry solutions help you design a solution that best fits your needs now and for the future as your company demands change. The remote viewing of real-time surveillance video, logging of personnel entry/exit, door status, window sensors and dedicated security system monitoring makes our solutions an excellent choice for your building’s automation system.

Remote Access

Maple Systems can serve as your guide, making it an easy process to join the next evolution of automated control. Maple Systems HMIs, Gateways, and Industrial PCs are your gateway to the IIoT. Our products are an access point enabling operating equipment in the field or on the plant floor to connect to information technologies of the World Wide Web, databases, smart phones, analytic software, and more. Achieve better access to invaluable data and open up a world of possibilities for your business.

Customer Service / Warranty

At Maple Systems, providing exceptional customer service is our top priority. As a valued customer, you’ll work with a dedicated Account Manager who knows your business. They are ready to assist with any request: from starting a technical support case and checking order status to locating a missing invoice.

Our online customer portal makes it easy to manage your account anytime. You can view and print sales orders, track shipments, update shipping addresses, and access invoices or our secure payment portal 24/7, plus customers with specific permission levels can buy on terms and see established discounts directly on the website. For more details, contact your Account Manager.

Support & Service Resources

- Returns / Repairs

- Warranty Statement

- Start a Support Case

- Contact Sales

- How to Place an Order

- Online Account Benefits

- FAQs

SCADA

Maple Systems offers all the components you need to build your own supervisory data acquisition and control system. This ranges from simple stand-alone machines to sophisticated multi-device networked production lines and support for enterprise-level operations and IIoT functionalities that leverage cloud connectivity.

- Log data from your devices to aid in reporting, improve efficiency, and reduce downtime.

- Use it to plan routine maintenance with ease.

- Add IIoT functionality like MQTT, OPC UA, Ignition, SQL database integration, and more.

Our products can help you standardize communications between devices, gluing different systems together for one source to your SCADA. No need to redesign your entire application.

Keep the components that are already working for you, just add Maple Systems components to grow your abilities to supervise, control, and acquire data.

To learn more about how our products work together to create scalable SCADA solutions, visit our SCADA solutions page.