Skills you’ll gain: Learn the various types of programs, special configurations, and communication configurations to set-up your program.

Software Required

Hardware Required

- Maple Modular PLC’S – Any Maple Modular PLC can be used.

- Maple Micro PLC’S – Any Maple Micro PLC can be used.

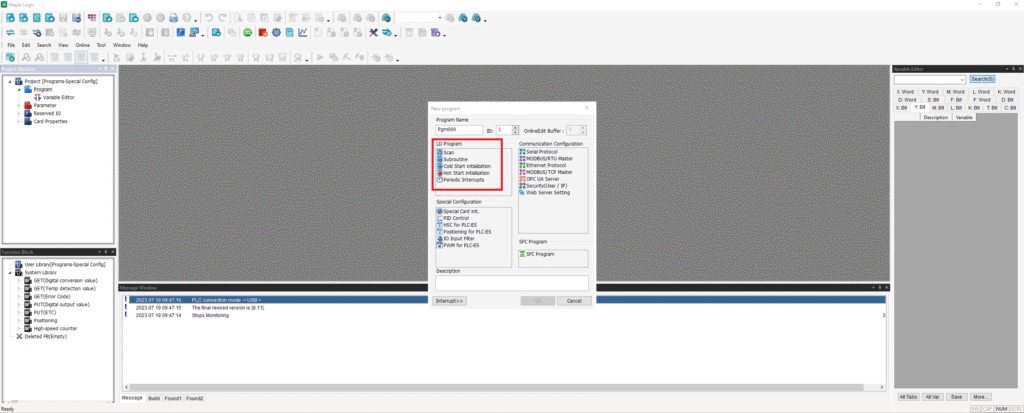

Ladder Diagram Programs

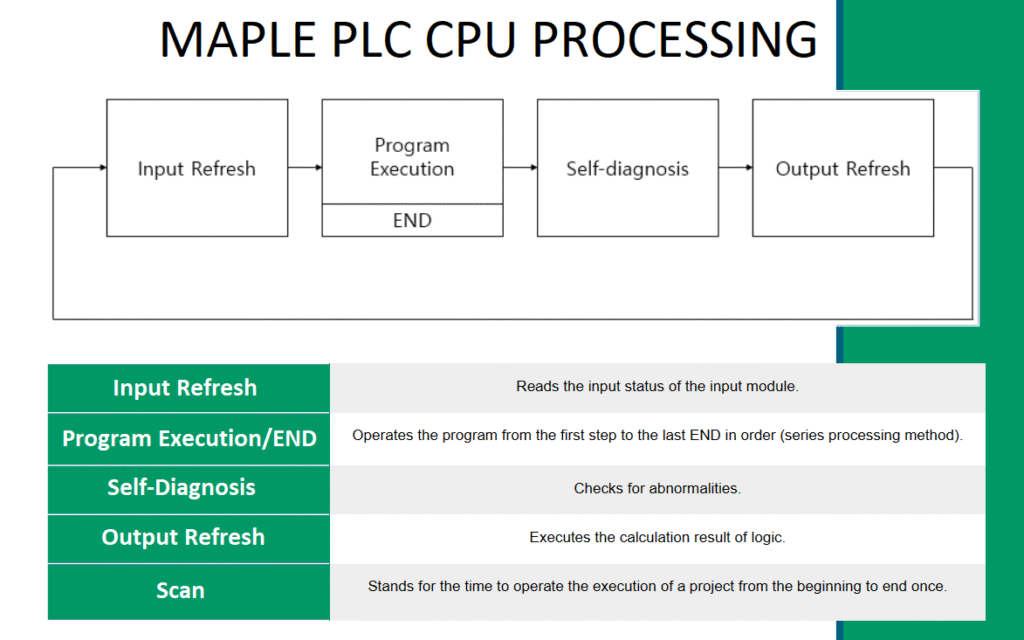

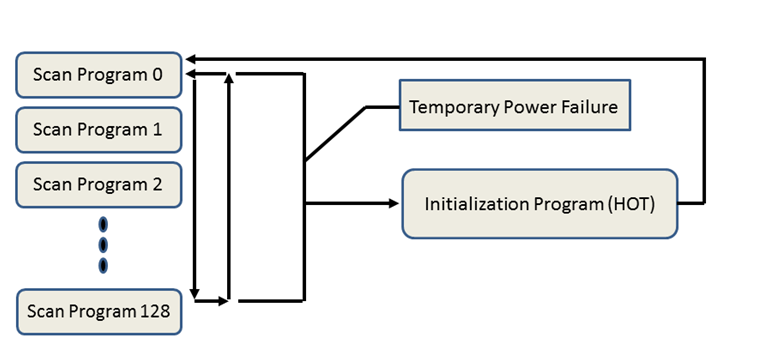

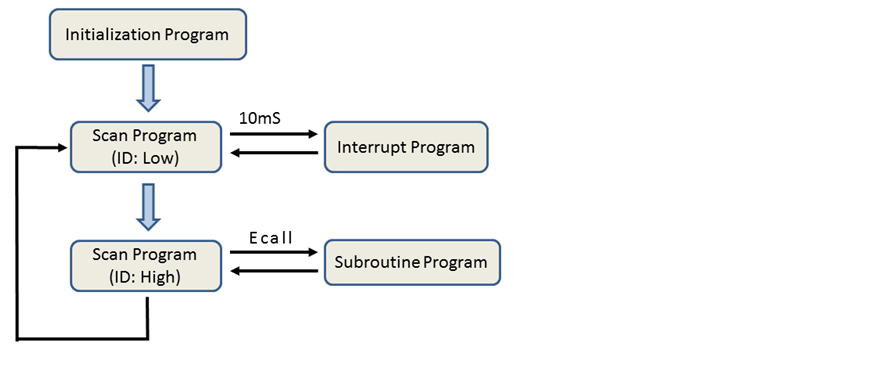

Scan Program

- Typical Program

- Depending how long the program is, this is routinely being ran every so often.

- A scan does not get told to start or stop unless the PLC is in off mode or powered off.

- When the PLC turns on, it starts to scan

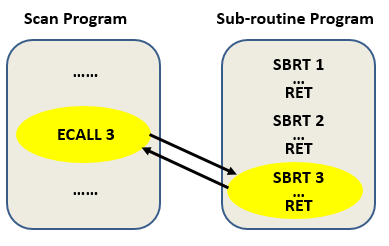

Subroutine

- This is a manual scan

- Does not routinely run on its own, it’s what you call upon.

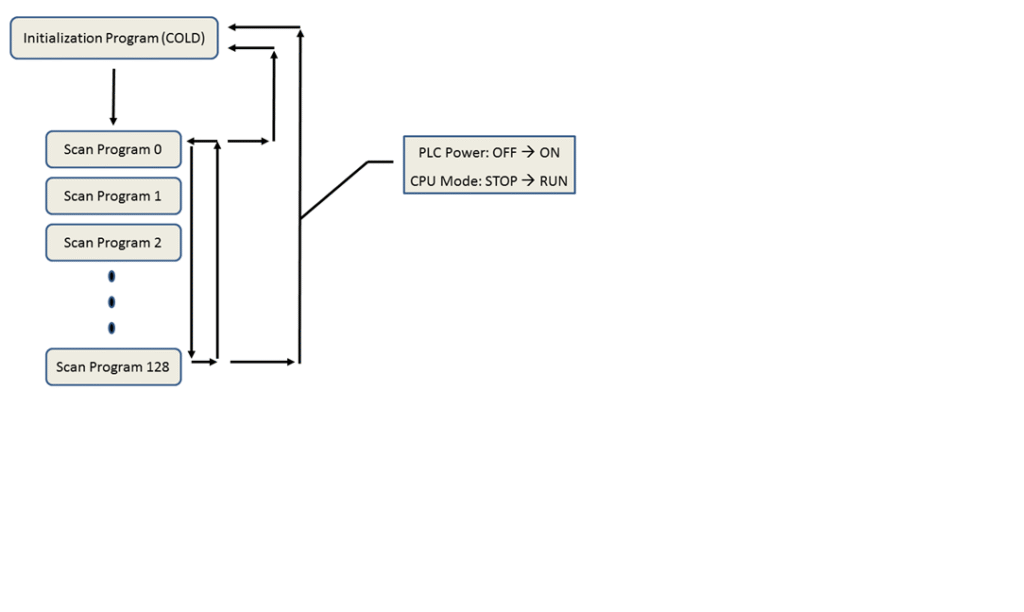

Cold Start Initialization

- Buffers values into data registers before the first scanned program begin.

Hot Start Initialization

- Only use if you are experienced.

- Used for expected time frame and only used during this time.

- If you go over the expected time frame, you will lose all your data.

Periodic Interrupts

- A manual scan

- Told by a timeframe to turn on and off

- Example: 10 milliseconds to 60 seconds or sometime after 45 minute it will run after that time.

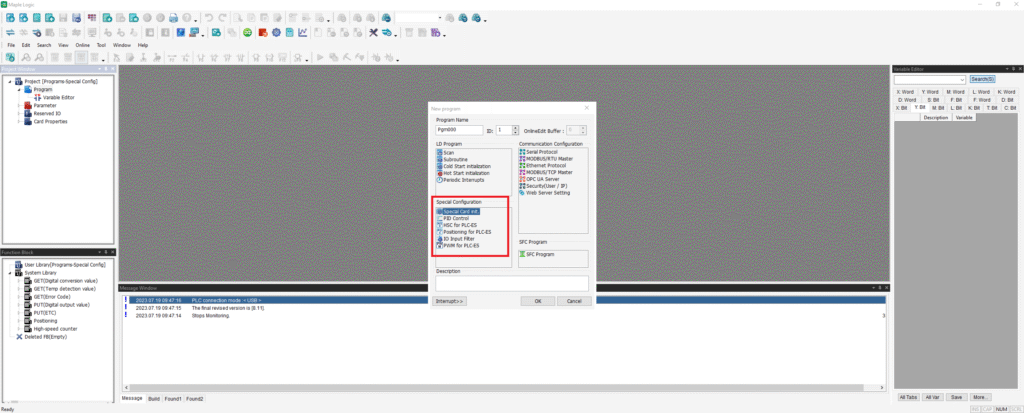

Special Configuration

Special Card Initialization

- Saves the setting values of a special card as a scanned program.

- Provides stored information automatically when there is a special card replacement that requires a reset without any additional operations connecting to the MapleLogic software.

- You DO NOT need the physical I/O card. You can still configure the special card settings.

To get a more detailed description on I/O Allocation please visit the “I/O Allocation and Online Communication” Tutorial Page.

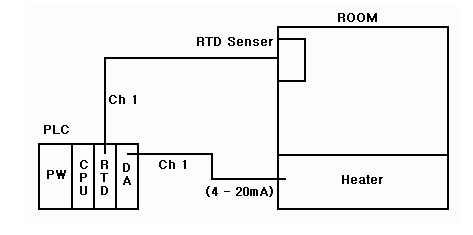

PID Control

- 32 Loops

- Auto-tuning

- Trend View

- Converts parameters to ladder diagram

Positioning (or Pulse Output)

- 1:1 ratio

- Up time is the same as the down time.

PWM (Pulse Width Modulation)

- Need a PWM expansion module SD0032PPWM front

- Up and down time is not the same

- Example 3:1 or 2:3 ratio

- Changing the width of the pulse PWM graph

I/O Input Filter

- Configures the I/O for the Maple Modular PLC’s

- Up to 11 available I/O Modules ca be configured

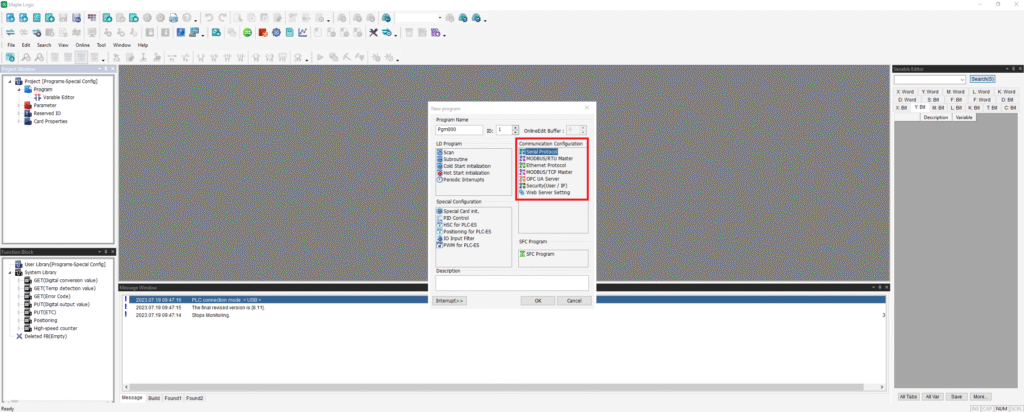

Communication Configuration

Serial Protocol (User Protocol)

- Serial Communication (RS-232 and RS-485)

- Example: Can be used with barcode scanners

Modbus Communication

- The Maple Modular and Maple Micro PLC’s can communicate with ANY device that has Modbus RTU and TCP/IP capabilities.

Ethernet Protocol

- A TCP/IP User Protocol

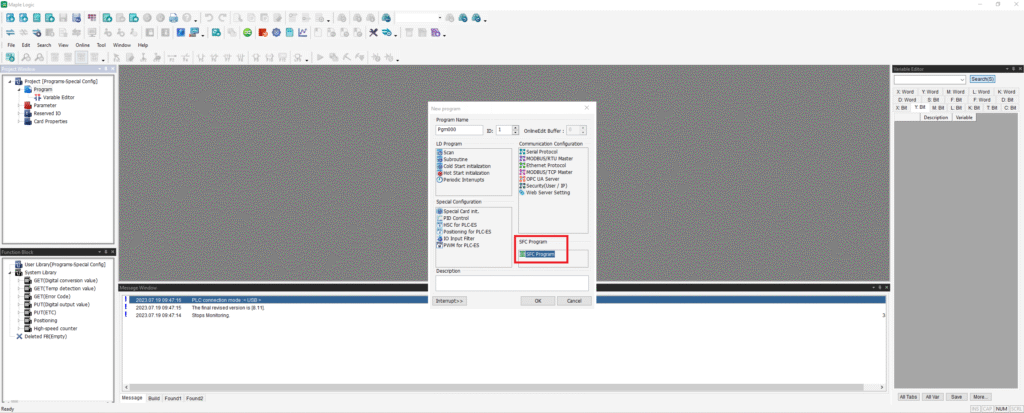

SFC Program

- Sequential Function Chart

- Allows for parallel processing

Resources & Documentation

Maple PLC/MapleLogic Resources

More Tutorials Sample Projects

See our Support Center for a complete list of Quick Start and Installation Guides

About the Author

Trusted source for industrial automation & control solutions

Follow Maple Systems: