Using Online/Offline Simulation in EZWare-500

Technical Note 1078

Applicable Model(s)

HMI500 Series

Title

Using Online/Offline Simulation in EZWare-500

Date

07/20/2005

Rev

01

P/N

0907-1078

Summary

You can save time when creating and testing a project by using EZware’s Simulation feature. Online/Offline simulation saves time because it does not require downloading a project to the HMI touch screen. In ‘Simulation’ mode, the PC computer displays a screen that simulates what is seen as if the HMI were executing the project file. You can use the mouse on your computer to simulate the touch operation of the touch-screen on the HMI. Simulation is also an easy way to distill screen shots for manuals and documentation.

Solution

Offline Simulation

Off-line simulation allows a project engineer to view their project look and operational ‘feel’ quickly without having to spend time downloading the project to the HMI. This simulation is great for visually seeing how the screen may look, or how the numeric keypad operates, etc. In this simulation mode, the PC acts as the HMI brain. The PC creates a dummy memory-map of all PLC registers used in the project, so there will never be a “PLC No Response ” generated with the off-line simulator. All the dummy-PLC registers are initialized to {0} when the simulation is started. Some actions are not possible within off-line simulation such as:

1.

The real time clock can be displayed (It uses the PCs time clock), but it cannot be changed. Changing the clock settings from within the off-line simulation mode is disabled.

2.

Some functionality of the project may not work as expected because it requires some pre-initialized values within the PLC registers. Since all registers in the PC start at value {0} they may produce unwanted results, such as alarms that occur when the bit is clear {0}.

Offline Simulation from within EasyBuilder:

1.

The project must be saved and compiled before the simulator can start.

2.

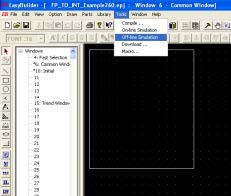

From the Tools menu, click Off–line Simulation or click the Off-line Simulation icon in the Standard toolbar.

3.

The ‘Simulation’ screen should appear on the PC monitor and display the start-up screen.

4.

To end off-line simulation, right click within the screen and click Exit or press the Space bar.

Offline Simulation from within EasyManager:

Simulation mode can also be started from EasyManager. EasyManager requires only the compiled project file (*.eob). This can be useful in situations in which you want to demonstrate changes made to a project for a client without giving them access to your project file.

1.

Start the EasyManager software.

2.

Click Offline–Simulator. The Open Project box appears.

3.

Browse for the compiled project file that you wish to simulate.

4.

Click Open. The simulation screen should appear.

5.

To end off-line simulation, right click within the screen and click Exit or press the Space

bar.

Online Simulation

On-Line simulation mode is similar to the Off-line simulation except that the PC tries to communicate with the PLC instead of creating dummy-PLC registers in memory. On-line simulation has two modes, ‘Normal’ mode and ‘Direct’ mode. In the Normal mode, the PC computer requires an HMI touch screen. The configuration cable is attached from the PC to the HMI screen, and the communication cable is attached between the HMI and the PLC. When the on-line simulation is started it will attempt to communicate to the PLC using the HMI’s communication port(s). The HMI will switch to a text mode and display polling information during simulation.

In the ‘Direct’ mode, the PC acts as the HMI and does not require the physical touch screen. The PC

will directly connect to the PLC using the PC’s COM port(s). If the PLC I/F port selected in the

project is for RS232, the simulation will then utilize the PC’s COM port selected in the Easy

Manager software. The communication parameters will be initialized the same as what the project

dictates. NOTE: This ‘direct’ mode will only operate for 10 minutes at a time, and then it will

disconnect communications. You may immediately run it again. Because the on-line simulation

mode communicates to a real PLC, the simulation will show actual bit register states and word

register values. Also, if there is a problem in communicating with the PLC, the same error will show

up on the simulator screen as if the project were downloaded to the HMI. If an error pops up, such

as “PLC No Response”, the problem could be due to:

- The communication cable is not correct (check wiring, opens & shorts)

- The communication parameters are not correct (check baud, parity, stop/start bits, and

PLC station address, be sure they match between the project and the PLC) - Register addressing is incorrect format or is trying to access registers in the PLC that are

not available. To help with troubleshooting a register problem, see the “Troubleshooting

tools during simulation” section below.

On-line simulation (Normal mode):

1.

Be sure all cables are connected between the PC and the HMI, and also, between the HMI and the PLC.

2.

Start the EasyManager software.

3.

Clear the ‘Direct’ Online–Simulator box if checked.

4.

From EasyManager, Click Online–Simulator. Browse and open the project file that you wish to simulate.

-OR-

5.

From EasyBuilder, go to the Tools menu, click On–line Simulation or click the On-line Simulation icon in the Standard toolbar.

On-line simulation (Direct mode):

1.

Be sure you have a correct cable connected between the PC and the PLC. If the PLC has a download cable that is meant to be used from the PC’s COM port for downloading ladder logic, then this cable can be used, just set the I/F Port in the project for RS232.

2.

Start the EasyManager software.

3.

Check the ‘Direct’ Online–Simulator box if not checked.

4.

From EasyManager, Click Online–Simulator. Browse and open the compiled project file

that you wish to simulate.

-OR-

5.

From EasyBuilder, go to the Tools menu, click On–line Simulation or click the On-line

Simulation icon in the Standard toolbar.

Troubleshooting Tools During Simulation

Simulation mode allows additional functionality. By placing the mouse anywhere on the simulation screen and doing a right click, a new menu comes up with additional features.

Search

Allows searching the entire project for a particular PLC address. Check PLC and type the address. Searching can also be done by parts. Check Part and select the type of object.

PLC Monitor

Allows monitoring of the polling communication between the HMI and the PLC. This monitor can help troubleshoot register fault problems. Click on the “Block Capture” check box to view each time the HMI polls the PLC to grab a single, or a block of, register(s). Each poll tells from what window called it (Win000 are background tasks such as alarm scan objects), how long it took to get the data, what the address is, how many 16-bit words it grabbed, what the register type was, and if it failed to get the data, it will say “-FAIL” to the far right.

System Resource

Displays information about the availability of HMI resources, namely RAM memory, timers and

queues.

Data Monitor

Shows live PLC data polling based on individual object types.

Emulator Setting

Sets up how the Simulator appears and operates.

Print Screen (Preview) & (Save To File)

Prints a picture of the current screen displayed. To preview before printing, select Screen Preview. “Print screen to a file” will create a bitmap image of the screen.

Print Window (Preview) & (Save To File)

To print object/address information within a window, select Window printing and select the “Table” radio button. To preview, select Window Preview. “Print window to a file creates a bitmap image of the screen data.

Capturing Simulation Screens to Use as Documentation

To capture screen pictures for creating documentation, run the simulator (either on-line or off-line) and when you are displaying the window you wish to capture, hold the ALT key down and push the PRINT SCREEN key on your keyboard. This will send a bitmap image of the simulation window only to the clipboard. Now open a word document or your publishing software and PASTE the image from the clipboard.

More Information

For more information regarding Simulation Mode, please refer to Chapter 3, Simulator Mode in the

HMI500 Series Installation and Operation Manual that is supplied on CD ROM with the

EZware-500 configuration software.