Can I use Ethernet to Read and Write Values to my HMI?

Technical Note 1084

Applicable Model(s)

HMI500 Series

Title

Can I use Ethernet to Read and Write Values to my HMI?

Date

01/23/2004

Rev

00

P/N

0907-1084

Summary

The HMI 500 Series now has Ethernet ports on the backs of the displays, allowing users to connect an HMI to another HMI via Ethernet in a master/slave relationship. The master HMI may be directly connected to a PLC via RS-232 or RS-485. The slave HMI then communicates through the master HMI to get data from the PLC. No additional communications modules are required which provides an effective and inexpensive way to connect multiple OITs to a single PLC.

Ethernet may also be used to connect a PC to an HMI, where the PC functions as a slave HMI. This format enables you to run an Easy Builder program on your PC which (via Ethernet) communicates with HMI’s elsewhere.

Solution

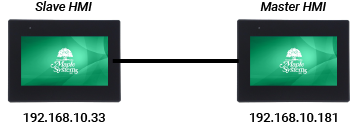

HMI (Master) to HMI (Slave)

Before Ethernet was available, multiple HMI’s needed to be daisy chained together via RS-232 (see Tech. Note 1075). With the addition of Ethernet ports however, one HMI may be connected to another via Ethernet, providing a faster response time and ability to go farther distances (100m). Currently, only one slave HMI can be connected to one master HMI using Ethernet. To set up each HMI, follow the instructions below:

Hardware Connection

It is necessary that a crossover Ethernet cable is used between the two HMI’s.

Software Connection

You must configure the OIT that connects to the PLC as the master. The other OIT should be configured as a slave OIT.

To Configure the Master OIT

1.

In the Master OIT’s project, click on Edit, System Parameters and select the PLC tab.

2.

Select Master from the Multiple HMI box.

3.

Select Ethernet in the Connect I/F box directly under the Multiple HMI “Master” box.

4.

Select a unique Local IP address to assign to this Master HMI. In the diagram above, 192.168.10.181 was selected. Also assign a Subnetwork Mask (i.e. 255.255.255.0). Note that if you have a router in the setup, the router’s IP address goes in the “Default Route IP address” section. If you don’t have a router it may be ignored.

To Configure the Slave OIT

1.

In the Slave OIT’s project, click on Edit, System Parameters and select the PLC tab.

2.

Select Slave from the Multiple HMI box.

3.

Select Ethernet in the Connect I/F box directly under the Multiple HMI “Slave” box.

4.

Select a unique Local IP address to assign to this Slave HMI. In the diagram above, 192.168.10.33 was selected. Type the IP address you assigned to the Master in Server IP Address. Also assign a Subnetwork Mask and Default Route IP address to match those of the master.

5.

Select a unique station number in the HMI station no. box for the slave HMI and click OK.

Skip to the section entitled “Sharing Data between the Master, Slave, & PLC” of this document to determine how to address PLC and Master HMI memory from your slave HMI.”

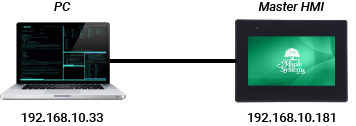

HMI (Master) to PC (Slave)

Hardware Connection

A crossover Ethernet cable is used directly between the HMI and the PC as shown below.

Software Connection

You must configure the OIT that connects to the PLC as the master. The Computer will be

configured as a Slave.

To configure the Master OIT

1.

In the Master OIT’s project, click on Edit, System Parameters and select the PLC tab.

2.

Select Master from the Multiple HMI box.

3.

Select Ethernet in the Connect I/F box directly under the Multiple HMI “Master” box.

4.

Select a unique Local IP address to assign to this Master HMI. In the diagram above, we have selected 192.168.10.181. Also assign a Subnetwork Mask (i.e. 255.255.255.0). Note that if you have a router in the setup, the router’s IP address goes in the “Default Route IP address” section. Otherwise, it may be ignored.

To configure the PC (serving as the Slave OIT)

1.

In the Slave OIT’s project, click the Edit, System Parameters and select the PLC tab.

2.

Select Slave from the Multiple HMI box.

3.

Select Ethernet in the Connect I/F box directly under the Multiple HMI “Slave” box.

4.

Because the PC has it’s own IP address, the Local IP Address does not matter. The PC’s IP address will be used automatically.

5.

Type the IP address you assigned to the Master HMI in Server IP Address. Also assign a Subnetwork Mask and Default Route IP address to match those of the master.

6.

Save and compile your project. Open Easy Manager and make sure the Direct Online Simulation Box is checked. Also change the Com port to COM 1 (if it’s not already selected). Unplug the configuration cable from the Master HMI.

7.

Press the Online Simulation button and browse for your slave project. You may now read/write to the values in the Master HMI (or the PLC it’s connected to), right from your computer.

Skip to the section entitled “Sharing Data between the Master, Slave, & PLC” of this document to determine how to address PLC and Master HMI memory from your slave HMI.”

Master HMI to Router to Slave HMI (or PC Serving as a Slave)

It is also possible to put a Router in between the Master and Slave HMIs or Master HMI and PC as

shown in the diagrams below. A router allows you to connect different Ethernet areas, providing a

method to have wireless communication between the devices.

-OR-

To Configure the Master OIT

1.

In the Master OIT’s project, click on Edit, System Parameters and select the PLC tab.

2.

Select Master from the Multiple HMI box.

3.

Select Ethernet in the Connect I/F box directly under the Multiple HMI “Master” box.

4.

Select a unique Local IP address to assign to this Master HMI. In the diagram above, we have selected 210.66.120.179. Also assign a Subnetwork Mask (i.e. 255.255.255.0). The router’s IP address goes in the “Default Route IP address” section therefore we set ours to 192.168.10.1.

To configure the PC (serving as the Slave OIT)

1.

In the Slave OIT’s project, click the Edit, System Parameters and select the PLC tab.

2.

Select Slave from the Multiple HMI box.

3.

Select Ethernet in the Connect I/F box directly under the Multiple HMI “Slave” box.

4.

You may enter the address of the Slave HMI in the Local IP address. In this project, we have selected 192.168.10.181. If you are using a PC as the slave HMI, the Local IP Address does not matter since the PC has it’s own IP address. The PC’s IP address will be used automatically.

5.

Type the IP address you assigned to the Master HMI in Server IP Address. In this case, we would enter 210.66.120.179. Also assign a Subnetwork Mask and Default Route IP address to match those of the master.

6.

Save and compile your project. If you are using a Slave HMI, download the slave project to the HMI. If you are using a PC serving as a slave, open Easy Manager and make sure the Direct Online Simulation Box is checked. Also change the Com port to COM 1 (if it’s not already selected). Unplug the configuration cable from the Master HMI. Press the Online Simulation button and browse for your slave project.

7.

You may now read/write to the values in the Master HMI (or the PLC it’s connected to), from your slave HMI or computer.

Sharing Data Between the Master, Slave, and PLC

Master – PLC

The master OIT will be programmed just as if it were the only OIT connected to the PLC.

Master – Slave

Any local word registers (LW) or local bits (LB) located in the Master OIT can be accessed and

written to by the Slave. Do this by using the Ms_LW and Ms_LB memory. For example, if the

master OIT is storing data in LW10, the slave OIT can access that data by using Ms_LW10.

Slave – PLC

The slave OIT’s may access data in the PLC in 2 ways:

1.

It may read/write directly to the PLC addresses (as though it were the only OIT connected to the PLC).

2.

It may write to the local words/bits in the master OIT (via Ms_LW, & Ms_LB registers) and those values may be transferred to the PLC by setting up a data transfer object in the master OIT program.

NOTE: If the master and the slave OIT’s are all accessing the same areas of memory in the PLC, this method is more efficient because the time required to get information from the PLC is reduced.

More Information

For more information regarding Ethernet connections, please contact Maple Systems Technical Support.