JM Controls & Electric Solutions with Maple HMIs

Design multi-line operator stations for control and monitoring in a large agricultural processing facility

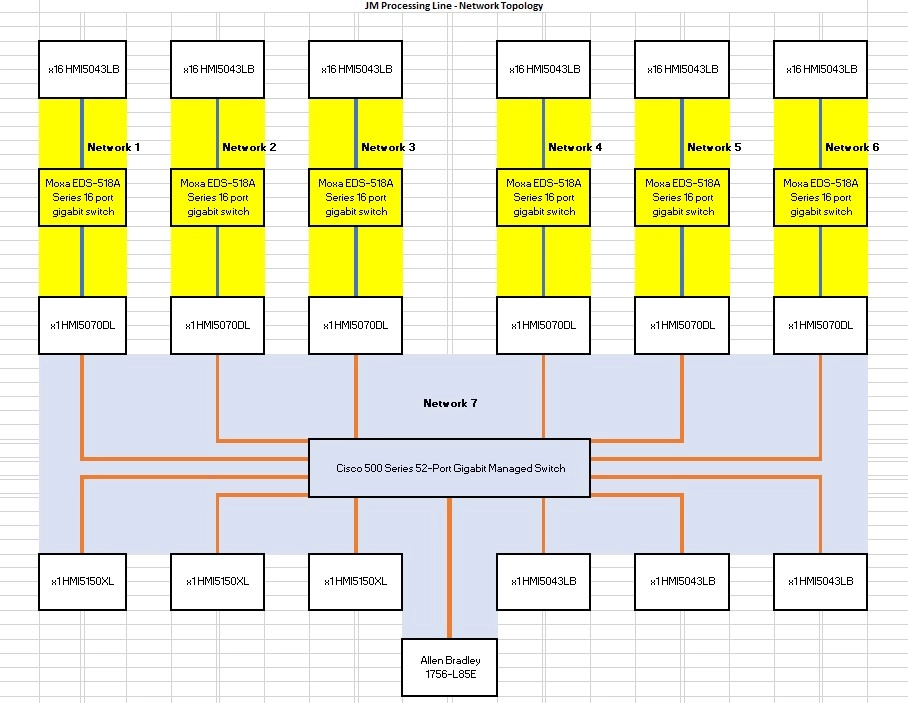

JM Controls and Electric is a System Integrator located in Ontario Canada and they were hired to engineer, layout, design, and install a large system to sort and weight marijuana buds within a multi-station facility. There would be 5 lines and each line would have 96 4.3” HMIs, 6 7.0″ HMIs, and 6 15” HMIs, communicating over ethernet via several switches to an Allen Bradley ControlLogix PLC.

JM Controls & Electric

Industry: Electronic

Location: Ontario, Canada

Company Size: 25 people

Year founded: 2014

Requirements

- Interface with an Allen-Bradley PLC

- Needed the touch screen controller to be low-cost to keep overall cost down.

- Needed the touch screen controller to be CE UL rated.

- JM Controls was looking for a control product that would act as the touch screen for the operator and control the hopper and weighed at each station.

- Show alarms on screen if mechanical equipment had issues.

- JM Controls’ engineers were not familiar with the setup on routing the data through the dual ethernet models.

- JM Controls is in a different time zone and country (Canada) which created additional consideration.

Testing

To facilitate the testing and prove out the solution, we set-up a test lab of 16 4.3” HMIs and 1 15” HMI at our facility.

Once the initial testing was validated, JM Controls shipped us the PLC, network switched, and power supplies, and we increased the test lab to 96 4.3” HMIs, 6 7” HMIs, and 6 15” HMIs.

Equipment JM Controls provided during testing:

Allen Bradley L85 PLC

(1) Main Cisco 52 port network switch

(6) Moxa 16 port switches from small sub-networks

(1) 24vdc power supply

Equipment Maple Systems provided during testing:

(99) HMI5043LB

(6) HMI5070DL (or equivalent dual ethernet model)

(3) HMI5150XL

All CAT5 cabling to connect to our switches

JM Controls’ Engineer worked with our lead Application Engineer for 2 days to prove out the system set-up. During the testing, we were able to validate communications between the HMIs and the PLC and that the project worked as expected.

Results

As a result of our combined efforts, JM Controls moved ahead with the purchase and installation of Maple Systems 500 4.3” HMIs, 18 7.0″ HMIs, and 18 15” HMIs into the production facility.

JM Controls and Electric was able to program the unit on their own, but we do offer Application Engineering services to program the unit for you if you do not have the time or resources. We can program the unit, and then train you on the real program so you can make changes in the future when integrator with your machine, if needed.

Our Value Promise

Long renowned in the Industrial Automation industry for the quality of technical support we have provided for decades, Maple Systems has a reputation for connecting customers with someone who knows our products inside and out. Whether it is one of our trusted System Integrator partners, Distributors, or our own engineering team, we are happy to connect you with a knowledgeable engineer dedicated to understanding your application.

Application Engineering

In an industry where every advantage counts, collaborating with a trusted partner will get your project where you want it to be, fast.

Supported Products

HMI Series

From basic functionality to IIoT advanced features, our touchscreen HMIs provides options worth weighing.