The Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is a system for engineers and operators to collect, share, and analyze data from connected devices on a factory floor. By linking devices to a network and sending their real-time data to local or cloud servers, teams can monitor, manage, and improve their systems more efficiently. Maple Systems products simplify bringing the Industrial IoT to life in your operation.

Everything’s connected in the Industrial IoT

Connection means everything in modern industry. But without context, even the most connected systems won’t tell you much. That’s why understanding how devices interact on a factory floor is so valuable. Today, the Industrial IoT makes connecting and understanding systems easier than ever. Like the Internet of Things (IoT), the Industrial IoT connects every device in a factory to a network. Doing this lets operators monitor activity, review historical data, and reveal patterns to guide real-time decision making. By providing engineers with always-up-to-date system information, they can reliably, precisely, and consistently tune their automation and control scenarios at a moment’s notice.

Industrial IoT infrastructure

The sensors, actuators, and field devices controlling and monitoring systems gather lots of data daily. This data provides operators with powerful insights when together. But accessing this data used to require operators to physically connect devices, often with industrial network switches, and manually compile it for insights. The Industrial IoT changed that.

Modern devices are built standard with smart capabilities, allowing them to connect directly the internet and send data in real time. This simplifies network setup and streamlines dataflow between field devices and system operators by creating a “net of things.” Operators can then immediately use this data to fine-tune their systems’ tasks.

The Industrial IoT’s key features and benefits

- Automated reports for better documentation

- Broad device support for easier scaling

- Cloud-ready for advanced analytics and insights

- Custom dashboards for tailored system views

- Edge processing to lower bandwidth and cloud costs

- Historical data tracking to spot trends and issues

- Instant email alerts for alarms and updates

- Predictive maintenance to prevent unexpected failures

- Protocol conversion for seamless hardware integration

- Real-time data transfer for faster, smarter decisions

- Remote monitoring and control from anywhere

- Secure data handling with advanced encryption

Understanding the Industrial IoT infrastructure

Industrial devices

Data in an Industrial IoT system starts with field devices: sensors, actuators, thermocouples, and VFDs that monitor and control equipment. These devices generate raw data that’s collected by IO modules and sent to control devices like PLCs or RTUs. Control devices translate raw data into standardized industrial communication protocols, like EtherNet/IP or Modbus. From there, it can be displayed on HMIs for real-time monitoring and control or passed to an edge gateway for further processing.

Edge gateways

Edge gateways sit at the boundary of factory networks, translating industrial data from control systems and HMIs into Industrial IoT-friendly protocols like MQTT or OPC UA. This translation enables seamless communication with cloud or local networks, allowing data to flow beyond the factory floor. While edge gateways can be standalone devices, many Maple Systems HMIs also function as gateways, supporting over 300 industrial protocols to connect with nearly any equipment in your setup.

The cloud

The cloud gives industrial operations a secure, scalable place to store, process, and analyze data. Platforms like AWS, Azure, and Google Cloud eliminate the cost and complexity of local servers. They also offer powerful tools for real-time processing, analytics, machine learning, and remote monitoring. The cloud links operations to enterprise-level tools that turn raw data into actionable insights.

Enterprise applications

At the end of the data flow are enterprise applications—software tools that turn all the collected and processed data into clear, useful insights. SCADA, MES, and platforms like AVEVA Edge help operators monitor performance, schedule maintenance, reduce downtime, and align production with business goals. These applications close the loop in an IIoT system, enabling smarter decisions and more efficient, connected operations.

Maple Systems’ Industrial IoT solutions

Remote access

Staying connected to your equipment is essential in the Industrial IoT, and Maple Systems makes it easy with multiple remote access options. EasyAccess 2.0 provides secure, VPN-based global connectivity to your HMI and connected PLCs with no complex setup. For local access, you can use VNC to view your HMI over the network, cMT Viewer to monitor multiple cMT HMIs from a single device, or WebView to access your HMI via any browser. We also offer Web HMIs built for HTML5-based visualization, giving you fast, app-free access to real-time control from any browser-enabled device.

Edge gateways

Maple Systems’ edge gateways connect your industrial equipment to the cloud by collecting data from sensors, PLCs, and other devices, converting it into IIoT-ready formats, and sending it to local servers, remote dashboards, or cloud platforms. With support for 400+ industrial protocols and IIoT standards like MQTT and OPC UA, they enable secure, efficient data flow between OT and IT systems. Many of our HMIs and industrial PCs include built-in gateway functionality, reducing hardware requirements and simplifying setup. Whether you’re monitoring production, energy use, or predictive maintenance, our edge gateways help you get more from your data.

MQTT

MQTT is a lightweight, open messaging protocol built for efficient, real-time communication—ideal for edge devices and remote sensors where bandwidth is limited. It uses a publish/subscribe model to handle data like temperature, pressure, and energy usage with minimal overhead. Many Maple Systems products support MQTT, making it easy to send data to cloud platforms, local servers, or remote systems and stay connected, even in challenging environments.

OPC UA

OPC UA is a widely used, secure communication protocol that organizes data into easy-to-understand objects and works on a Client/Server model—making it ideal for connecting with SCADA, MES, and ERP systems. It features built-in encryption to protect your data during transfer. Maple Systems offers products with built-in OPC UA Server support, and all our HMIs can act as OPC UA Clients, enabling smooth, secure integration across your operations.

Supervisory Control and Data Acquisition (SCADA)

SCADA software gives you full visibility and control over your industrial systems, and Maple Systems makes it easy with AVEVA Edge SCADA. This software is ideal for everything from single machines to complex, cloud-enabled IIoT setups. You can start logging data immediately to improve reporting, reduce downtime, and plan maintenance proactively. With support for MQTT, OPC UA, Ignition, and SQL databases, our products seamlessly connect devices across brands and protocols so you can enhance your system without replacing what already works.

SQL databases

Some Maple Systems HMIs can send machine data, like metrics, production totals, or recipes, straight to your SQL database without needing extra software in the middle. That means less complexity and faster setup. You can manage that data later with batch operations, making it easy to organize or analyze at scale. Plus, with the built-in database query viewer, your machines can also pull info directly from your central SQL database whenever they need it. It’s a simple way to keep everything connected and efficient.

Maple Systems’ solutions in action

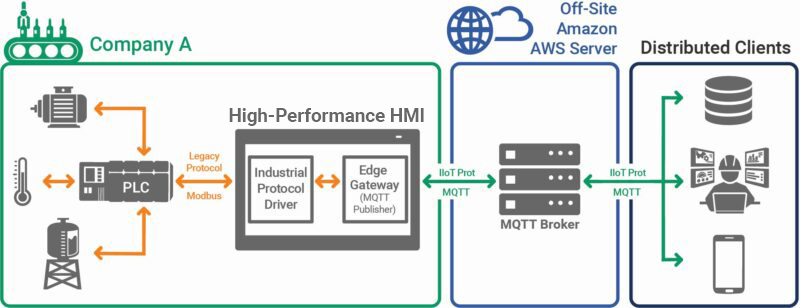

A Global Network

Company A needed a smarter way to manage machines across multiple sites without constant travel. To stay competitive, they turned to the Industrial IoT, using EasyAccess 2.0 for secure remote support and MQTT for reliable, cloud-friendly data transfer, especially with their existing AWS setup. However, their machines used different protocols and couldn’t easily communicate. Maple Systems’ cMT3092X HMI solved this. With dual-Ethernet ports and support for 300+ protocols, it acted as both a user interface and an edge gateway, connecting all systems to the IIoT. Now, Company A can monitor machines in real time, send alerts, and troubleshoot remotely without on-site IT. Data flows securely to AWS, enabling faster issue resolution, remote updates, predictive maintenance, and better business insights. The Industrial IoT helped them save time, boost efficiency, and improve customer support globally.

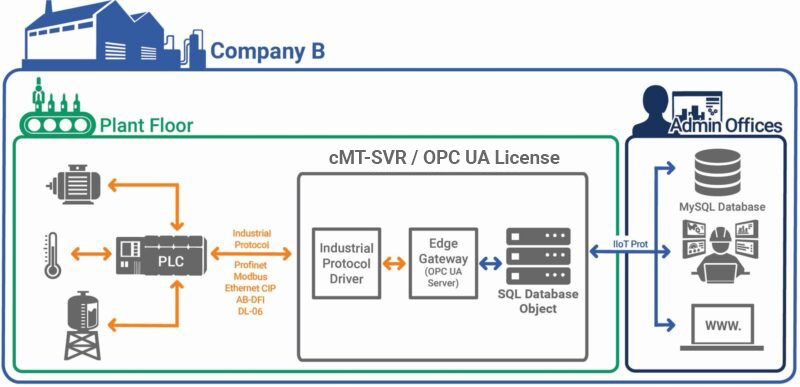

A Single Factory

Company B is a small food processing plant that faced tight budgets and incompatible systems. It already used OPC UA with a SCADA system and MySQL database but needed a low-cost way to unify its networks without buying new servers or HMIs. The company chose Maple Systems’ compact, screenless cMT-SVR with an OPC UA license. It fit into small spaces, supported both Ethernet and serial networks, and required no extra displays. With it, the company configured communication drivers and set up an OPC UA server to tag and send plant floor data to their existing SCADA and MySQL systems for real-time analytics. The cMT-SVR’s remote access features made management easier. Using the free cMT Viewer app, staff could monitor machines from any device and receive instant alerts. By centralizing data, Company B reduced costs, improved uptime, and extended machine life.

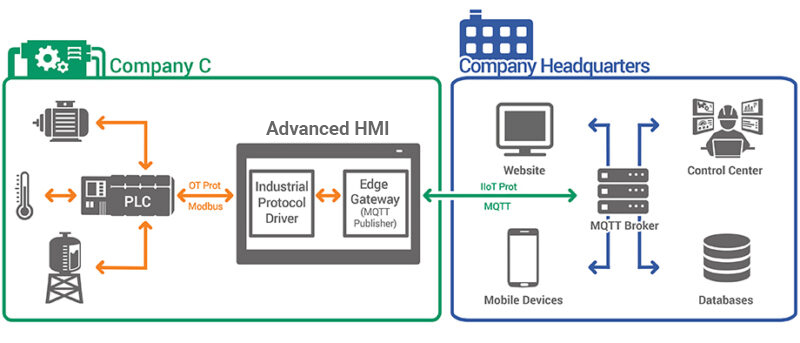

System Integrator

Company C is a small SaaS-based integrator. It needed a secure, flexible solution to manage diverse PLC brands, meet strict IT policies, and provide fast remote support to customers. Its ideal system had to support multiple communication protocols, enable secure remote access, integrate with MQTT, be reliable, and be easy to maintain. With Maple System’s help, they deployed a modern Industrial IoT setup using their in-house MQTT broker, avoiding cloud services while gaining full visibility into customer systems. This allowed real-time monitoring of energy use, performance, and maintenance needs. The result: fewer emergency calls, improved energy efficiency, and faster service. Company C became a proactive partner, not just a vendor. In the end, they delivered better support, reduced costs, and greater value for their customers.