Choosing the Right Waterproof Panel PC

For facilities that rely on strict sanitation, outdoor operation, or heavy washdown procedures, choosing the right waterproof panel PC can make or break your operation. Discover the key features to look for when choosing a waterproof computer, and dive into some industry-specific use-cases.

In industries where equipment is exposed to constant washdowns, high-pressure cleaning, corrosive chemicals, or outdoor weather conditions, a standard panel PC simply won’t survive. That’s why waterproof industrial PCs have become essential across any industries that do work in, or create these harsh environments.

Choosing the right waterproof panel PC ensures not only long-term reliability, but also compliance, safety and uninterrupted productivity. In order to make an informed decision, there are various key factors of panel PCs such as IP ratings, construction materials, and processing power that will help you decide on which panel PC is right for you.

What Makes a PC Waterproof? IP Ratings Explained

First off, defining Ingress Protection (IP) ratings is essential for understanding the importance of a waterproof panel PC.

An IP rating of 66 means that the device is dust-tight and protected against powerful cold water sprays or jets. This rating shields the device from natural weather ingress such as rain, snow, and general washdown, but will not protect the device against full submersion or harsh chemicals.

An IP rating of 69K on the other hand, means that the device is not only dust-tight, but the device can also withstand high-pressure, high-temperature water or corrosive cleaning agents. IP69K devices can resist water up to 80°C at 30 bar of pressure, making them suitable for hygiene-critical industries.

For more info, feel free to check out this FAQ on IP ratings. On top of Ingress Protection, there are several other key features to consider when choosing the right waterproof panel PC.

Waterproof Panel PC Key Factors to Consider

When selecting a panel PC, you’ll need to consider the specific environmental, performance, and mounting requirements of your application.

1. Environmental Protection

A good first question to ask yourself is what kind of environmental protection you’ll need for your panel PC. Do you need resistance to water splashes or jets? Will the PC be exposed to dust, fine particulates, or heavy airborne contaminants? How often will the device undergo washdowns, and what kind of cleaning chemicals will be used?

[Maple Systems’ waterproof panel PCs] sport an IP66 and an IP69K rating

Another factor in environmental protection is the operating temperature range. For example, Maple Systems’ waterproof stainless-steel panel PCs support temperatures from 0–50°C, ensuring reliable performance in both chilled rooms and hot production areas with their fanless design.

2. Material and Construction

The panel PC’s construction and material directly influence durability and corrosion resistance, especially in environments with frequent chemical exposure.

304 stainless steel offers excellent corrosion resistance and stands up well to washdowns, salt exposure, and food-grade cleaners. Which allows our waterproof panel PCs to maintain structural integrity while protecting internal electronics from harsh conditions.

3. Performance and Processing Power

Whether you need your PC to simply display PLC/HMI values, or if you need it to run resource-intensive SCADA, database, or programming tools, or if you simply need instant access to your data.

Maple Systems’ waterproof panel PCs excel in this department with an Intel Celeron Quad-Core 2GHz Processor, Intel UHD graphics, and a selection of 8, 16, or 32 GB of DDR4 RAM, our waterproof panel PCs are equipped to handle visualization, logging, diagnostics, and control applications with ease.

4. Connectivity and Expansion

A panel PC would be incomplete if it weren’t able to communicate with other devices. The number and types of connections your waterproof PC includes is also a large factor to consider. Typically, you’ll want a panel PC that supports M12 connections.

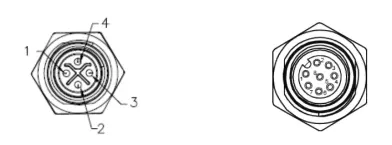

What is an M12 connection?

An M12 connection is a 12mm circular cable connection that’s threaded for screwing the cable connectors together, allowing for a fully protected electrical connection.

Our waterproof panel PCs feature exclusive M12 wired connections, including 2 USB connectors, 2 serial ports, 2 Ethernet ports, and an optional kit that includes Wi-Fi and Bluetooth 5.2 connectivity. In addition, Maple Systems offers M12 USB cables with 2 female USB ends, allowing for up to 4 USB connections on one PC.

5. Mounting Flexibility

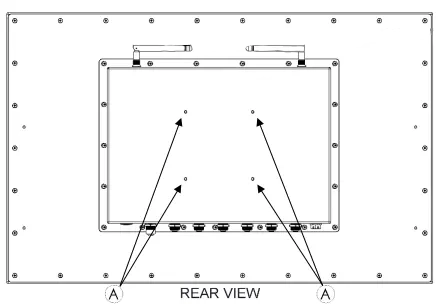

Another aspect to consider is where and how you’ll mount your panel PC. The typical go-to solution is using a VESA mount, especially for displays that need to be pivotable and moveable.

What is a VESA mount?

a VESA mount is a family of standards defined by the Video Electronics Standards Association for mounting monitors, televisions, and other display technologies. It typically includes 4 screw holes at equal distances on the back of the device.

With VESA and U-stand mounting options, our waterproof panel PCs follow the industry standards for equipment mounting. Allowing for either static mounting, or full-motion mounting arms, allowing you to mount the panel PC wherever and however you need it.

6. Display Features

And finally, you’ll want to think about the display options, like size, brightness, and touchscreen options.

Maple Systems’ line of waterproof computers feature 15″-23″ TFT LCD screens with projected Capacitive touchscreens, meaning you’ll be able to use our PCs touchscreens through a variety of gloves or liquid.

How to Choose the Right Waterproof PC for Your Industry

Waterproof panel PCs play a critical role in any operation where moisture, chemicals, or sanitation demands can damage traditional hardware. Let’s take a look at some common examples of industries that require high IP ratings for their panel PCs.

Food & Beverage Manufacturing

In food and beverage manufacturing, you frequently need to wash down your equipment to uphold USDA and FDA sanitation standards. So instead of taking the time to shut down equipment controllers and properly protecting them before a washdown. You could simply use an IP69K panel PC, which will withstand high-pressure, high-temperature water sprays, as well as corrosive cleaning materials, allowing you to keep your project and assembly line moving.

Pharmaceutical Production

For Pharmaceutical production environments, maintaining GMP compliance and sterile environments while simultaneously tracking batch processes can be a challenge. But with a sealed waterproof monitor, you won’t have to worry about contamination in cleanroom environments, giving you instant access to real-time data without compromising on GMP compliance.

Marine and Offshore Operations

If you find that your marine and offshore operations are coming to a standstill due to saltwater corrosion of electrical equipment, you’d need marine-grade stainless steel computers with fully sealed I/O ports to minimize equipment replacements, and maximize your navigation system reliability.

Chemical Processing Plants

With the many corrosive fumes and liquids damaging control systems in chemical processing plants, and many protective barriers limiting visibility and usability of those control systems. Chemical-resistant waterproof panel PCs from Maple Systems can serve as a rugged replacement that will stand up to the unique environmental hazards of chemical processing, while maintaining continuous monitoring.

Outdoor Kiosks and Transportation

Rain, snow, dirt, mud, dust, and extreme temperatures are all rather unkind to traditional monitoring and POS systems. But using an IP69K stainless-steel waterproof panel PC from Maple Systems helps ensure 24/7 operation on sunlight-readable displays that can handle temperatures between 0–50°C, eliminating the need for any sort of weather-related service interruptions.

Summary: The Right Waterproof Panel PC Choice

Choosing the right waterproof panel PC vs a water-resistant PC ensures long-term reliability, regulatory compliance, and maximum uptime, especially in industries where equipment is exposed to moisture, corrosive materials, heavy washdowns or extreme weather.

By evaluating IP ratings, material construction, processing power, mounting options, and connectivity, you can match your PC exactly to your application’s demands and avoid premature failures or costly downtime.

Find the Best Waterproof Computer Manufacturer

When it comes to waterproof computer systems and high-durability panel PCs, look no further than Maple Systems. We’ve been a trusted name in industrial automation since 1983, and our IP69K stainless steel waterproof panel PCs will stand up to any environment or programming need you can throw at it!

About the Author