What’s the difference between an industrial PC and a consumer PC?

The difference between an industrial PC and consumer PC can be hard to spot. Industrial PCs are built for the toughest environments where debris, moisture, temperatures, and vibrations are extremely volatile. Consumer PCs are built for basic tasks and can’t withstand harsh industrial conditions.

Industrial settings aren’t often pretty. Steel mills with powerful temperature fluctuations, offshore oil rigs battling coastal weather systems, and underground mines filled with toxic dust and gases are just a few examples of the rough environments industrial technology must endure. Without strong computers and equipment to keep these industries running, progress would grind to a halt.

Industrial PCs are at the heart of these operations, helping workers monitor and control the vital systems that keep people safe and machines running. But these aren’t the same consumer PCs you find at home. Industrial PCs are engineered for efficiency and can withstand the debris, moisture, extreme temperatures, and vibrations that would quickly wear down standard hardware. Consumer PCs are more basic machines and lack the durability to survive these conditions.

Industrial PC versus consumer PC

Think of an industrial PC as a tractor-trailer truck and a consumer PC as a passenger car. The tractor-trailer truck is a heavy-duty vehicle built for hard work, like transporting goods across long distances. A passenger car is mass-produced for day-to-day tasks, like commuting. Similarly, industrial PCs are built for heavy-duty computing in industrial settings, while consumer PCs are designed for everyday use in offices and homes.

While industrial PCs are commonly associated with extreme conditions, they are also valuable in more controlled environments like pharmaceutical manufacturing, water treatment facilities, and food processing plants. Their processing efficiency, long lifespan, and expandability make them a good option for any industry that requires reliable computing.

View the table below for a side-by-side comparison of industrial PCs’ and consumer PCs’ features and benefits.

| Industrial PC | Consumer PC | |

|---|---|---|

| Purpose | Built to last | General purpose |

| Cooling | – Passive (fanless) | – Air cooled – Liquid cooled |

| Cost | – Lower upkeep cost | – Higher upkeep cost |

| Durability | – Dust resistant – Moisture resistant – Shock resistant – Vibration resistant – Temperature resistant | – No standard resistances |

| Expandability | – Standard ports (USB, HDMI, PCIe, Ethernet…) – Specialized ports (GPIO, DIO…) – Legacy ports (RS-232, CAN Bus…) – Wi-Fi – Bluetooth | – Standard ports – Wi-Fi -Bluetooth |

| Efficiency | – Low maintenance – Optimized for high-speed processing | – High maintenance – Optimized for general performance (typically) |

| Operating system | – Windows – Windows IoT – Linux – RSOT | – Windows – macOS |

Benefits of an industrial PC

Durable

Industrial PCs often have robust, IP-rated aluminum or steel housings reinforced to protect against shocks and vibrations. They also use passive cooling systems, meaning they don’t rely on fans or pumps that could pull in debris and damage hardware. Some industrial PCs can even withstand massive temperature shifts ranging from -40°F to 280°F. And others have fully sealed seams for computing in wet or wash-down environments.

Efficient

Industrial PCs can regularly maintain heavy workloads and often run high-intensity software applications 24/7. Their specialized hardware and software mean they have longer lifecycles, reducing the need for frequent updates and replacements that consumer PCs require. Many industrial PCs have a compact design and take up much less space. This can help system engineers to integrate new computing requirements into already-crowded control environments.

Expandable

Some industrial PCs have fixed designs, but many are highly modular so operators can tailor them for their specific system needs. Modularity varies, but industrial PCs typically come with a mix of Ethernet, USB, HDMI, or DisplayPort connections. Industrial PCs also support many legacy communication protocols no longer standard on consumer PCs, like RS-232 or CAN Bus. More specialized industrial PCs include general-purpose I/O and digital I/O ports for adaptable communication.

Choosing an industrial PC

Just like consumer PCs, industrial PCs come in many shapes and sizes. The primary types include touchscreen panel PCs, embedded box PCs, Class 1 Div 2 PCs, and stainless steel PCs. Many features overlap from one to the other, but each industrial PC type has specific advantages suited for different automation and control scenarios.

Touchscreen

Touchscreen industrial PCs, also called panel PCs, have a built-in touchscreen interface, making them good for human-machine interface (HMI) applications. Factory automation, food processing, and pharmaceutical industries commonly use panel PCs, where intuitive touch controls improve efficiency. The biggest benefit of touchscreen industrial PCs is that they’re easy to interact with, allowing controllers to manage tasks quickly.

Embedded box

Embedded box industrial PCs are compact, rugged devices designed for space-constrained environments. Like consumer PCs, embedded box PCs come with most standard inputs and outputs and sometimes run on Windows or Linux operating systems. The major differences are box PCs’ fanless design and tough exteriors, making them perfect for applications requiring low power consumption, high reliability, and minimal maintenance.

Class 1 Div 2

Class 1 Div 2 industrial PCs are specialized for hazardous environments with flammable gases or vapors. Sealed closures, fanless designs, and spark-free and low surface temp materials make these some of the most resilient PCs available. Class 1 Div 2 PCs have strict safety standards and must be ignition and explosion proof. They’re often found in oil refineries, chemical plants, and mining operations. Class 1 Div 2 is a classification and can come as a touchscreen or an embedded box.

Stainless steel

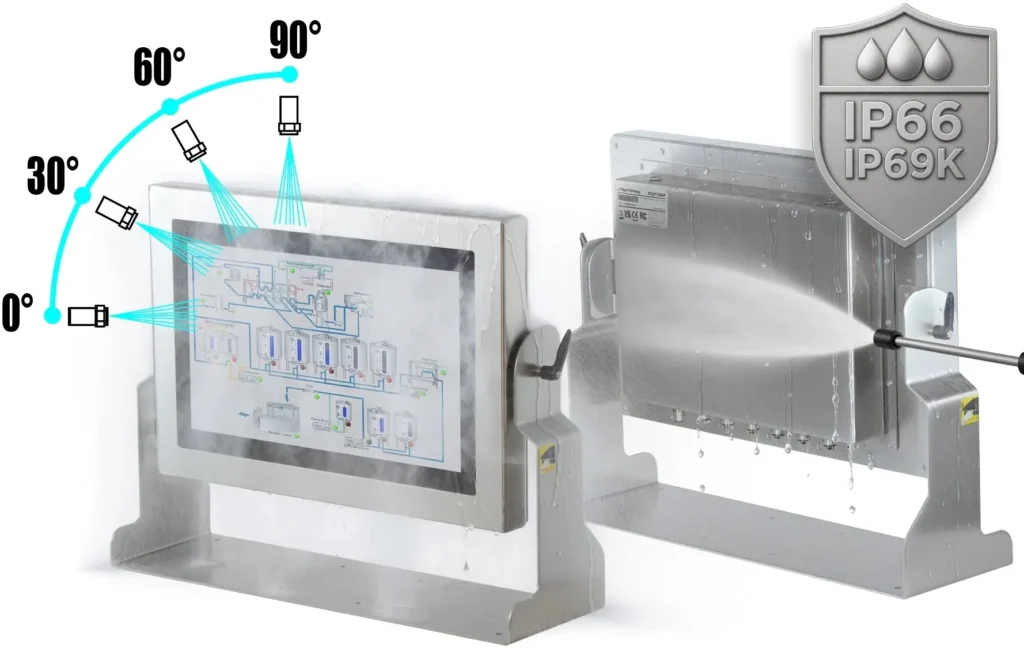

Stainless steel industrial PCs are highly resistant to corrosion, water, and contaminants, making them perfect for food and beverage processing, pharmaceuticals, and marine applications. They often have IP66- or IP66K/IP69K-rated enclosures that can withstand high-pressure washdowns, high temperatures, and chemical exposure. Stainless steel industrial PCs, just like Class 1 Div 2 industrial PCs, can come as a touchscreen or an embedded box. Not all stainless steel industrial PCs are classified as Class 1 Div 2 PCs.

Waterproof

Waterproof panel PCs will feature the same corrosion resistance and stainless steel construction as the stainless steel industrial PCs, but will also include a fanless design with full M12 connectors to achieve a full IP66 and IP69K rating from all sides. This will allow it to stand up to and remain functioning through high pressure water jets at 80°C and 30 bar of pressure. They also usually feature full 304 stainless steel construction for corrosion resistance and durability.

If you want more information on choosing an industrial PC, view our 10 Things to Consider When Choosing an Industrial PC article. For more general information on industrial PCs, head to our knowledge base. And if you want to learn more about the specific benefits or other features of industrial PCs, view our case studies. You can also browse our full range of industrial PCs if you’re ready to upgrade your system today.

Contact us

Contact our sales team for pricing, availability, and support.

Email [email protected] or call (425) 745-3229.

About the Author