M12 Connectors in Industrial Automation

M12 connectors are circular connectors featuring a 12mm locking thread, which is where their name originates. Engineers design these connectors for environments where reliability is crucial. M12 connectors resist moisture, dust, and vibration, originally serving sensor and actuator connections in automation. Today, they power a wide range of sectors, including automotive, manufacturing, and process control.

Industrial connectivity goes beyond simply making connections; it ensures your systems operate smoothly and reliably. To achieve this, you need solutions that are as dependable as the equipment they support. The automation industry relies on the rugged durability and versatile design of M12 connectors, making them the industry standard. Whether you’re wiring sensors on a high-speed assembly line or creating a robust Modbus network, choosing the right M12 solution guarantees that your systems remain online and perform efficiently. They are the backbone of reliable industrial communication.

What is an M12 Connector?

M12 circular connectors secure cable connections in rugged industrial environments. Their name derives from the 12mm metric locking thread, distinguishing them from the smaller 8mm M8 connectors. M12 connectors allow for power or data connections to remain completely water-proof and dust-proof without compromising on connection quality.

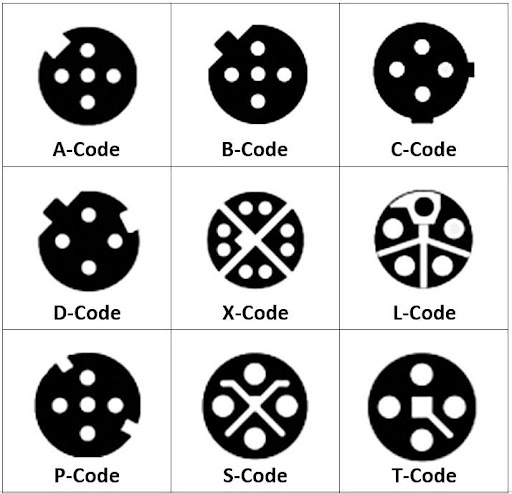

A standardized letter code assigns each M12 connector to a specific function, such as power, signal, or data transmission. For instance, Maple Systems’ panel PCs use S-Code connectors to route power to the device, and A-Code connectors for everything from USB to Ethernet to Serial connections.

Key Features of M12 Connectors

The standardized design of M12 connectors ensures compatibility, simplifies maintenance, and supports scalable industrial architectures. While re-wiring a cable connection introduces some up-front time investment, configuring your connections to fit an M-12 connector comes with various benefits like:

Durability:

The enclosed nature of an M-12 connection ensures the connected cable is built to withstand extreme industrial conditions; such as shock, temperature swings, chemicals, and UV exposure. An M-12 connection also allows the device and cable to maintain an IP rating of 67 or 69K to keep out dust and water. If you’d like more info on IP ratings, check out our FAQ on IP ratings

Secure & Reliable Connection:

A threaded screw-locking mechanism ensures a stable, vibration-resistant connection, preventing accidental disconnections and maintaining signal integrity. M-12 connectors also ensure a highly performant and low contact resistance connection, allowing for Gigabit Ethernet speeds suitable for IIoT connections.

Easy and Compact Design:

M-12 connections allow for smaller cable footprints when space is tight. They also offer a very simple installation. Simply screw in the cable, and you’re connected!

Ingress Protection:

M12 connectors commonly meet IP67, IP68, or IP69K ingress protection ratings. Therefore, making them well suited for environments requiring frequent cleaning with water, chemicals, or high-pressure spray. These ratings are essential for food processing, pharmaceutical manufacturing, water treatment, and outdoor industrial installations.

- P67 – Dust-tight and protected against temporary immersion

- IP68 – Protected against continuous immersion

- IP69K – Resistant to high-pressure, high-temperature washdown

Material Design:

Material selection ensures long-term durability and compatibility with washdown and sanitation requirements. To meet the demands of industrial environments, M12 connectors are available in:

- Nickel-plated brass for corrosion resistance and mechanical strength

- Stainless steel for hygienic and chemical-resistant applications

- Industrial-grade polymers for lightweight and corrosion-resistant designs

High-Density I/O:

M12 connectors facilitate high-density I/O on waterproof panel PCs without sacrificing enclosure integrity. As a result, designers can maximize connectivity while ensuring robust environmental protection and simplified cable routing.

Applications for M12 Connectors

M12 connectors are primarily used in industrial automation, robotics, and manufacturing for robust, reliable connections in harsh environments, linking sensors, actuators, and PLCs, but also power and Ethernet. They are also critical in transportation, medical devices, and agriculture for data/power transmission in demanding conditions, from low-power sensors to high-power drives and 1Gb Ethernet.

Key Application Areas:

- Factory Automation: Connecting sensors, encoders, valves, and controllers for machine control, vision systems, and PLCs.

- Industrial Ethernet: Supporting high-speed networks (like Ethernet/IP, Profinet) with D-coded (100Mbit) and X-coded (10Gbit) versions.

- Robotics: Linking robotic arms and mobile robots due to their compact size and vibration resistance.

- Transportation: Used in railway systems for passenger information, surveillance, and control systems.

- Medical Technology: Found in imaging systems (MRI, CT), diagnostic tools, and patient monitoring devices for reliable data.

- Power Distribution: S-coded and K-coded for AC power (drives, converters) and T-coded/L-coded for DC power (LEDs, drives).

- Smart Agriculture: Connecting GPS, sensors, and automation in outdoor, demanding conditions.

Use Cases of M12 Connectors

Different applications require different M12 coding types. Each coding prevents mis-mating and is optimized for specific electrical requirements, ensuring signal integrity, safety, and long-term reliability in industrial PC systems.

Factory Automation & Robotics: Connecting PLCs to I/O blocks, robotic arms, and conveyor systems where constant vibration would disconnect standard RJ45 ports.

Transportation: Used in railway signaling, rolling stock communication (PIS), and commercial vehicle electronic systems because they withstand extreme shocks and weather.

Food & Beverage Processing: Stainless steel, IP69K-rated versions are used in facilities that require high-pressure, high-temperature washdowns for sanitation.

Renewable Energy: Integrated into solar farms and wind turbine sensors to ensure stable data and power transmission in remote, outdoor settings.

Medical Equipment: Employed in imaging devices (MRI, CT scanners) and patient monitors for secure, reliable connectivity in critical diagnostics.

Final Thoughts

M12 connectors are not just a cabling choice—they are a reliability strategy. By delivering secure connections, environmental protection, and standardized compatibility, M12 solutions help industrial systems stay online, reduce downtime, and scale confidently as automation and IIoT demands grow.

This is why Maple Systems’ Waterproof panel PCs and C1D2 rated AEx PCs are equipped with M-12 connectors, to ensure that they not only stay connected, but also safe and reliable.

About the Author